When it comes to optimizing warehouse operations, one area that often gets overlooked is the proper maintenance of forklift batteries. Forklifts are essential tools in warehouses for moving heavy loads and maximizing productivity. However, if the batteries are not properly watered, it can lead to decreased performance, reduced battery life, and potential safety hazards.

The Importance of Properly Watering Forklift Batteries

Forklift batteries operate by converting chemical energy into electrical energy, which powers the forklift. These batteries require regular watering to maintain their performance and longevity. When the water level in a forklift battery is too low, it can lead to several issues:

- Reduced battery capacity: Low water levels in the battery can result in decreased capacity, meaning that the battery won’t hold as much charge as it should. This can lead to shorter runtimes and more frequent recharging.

- Decreased battery life: Insufficient watering can cause irreversible damage to the battery plates, leading to a shortened lifespan. This means that the forklift battery will need to be replaced more frequently, resulting in higher costs for the warehouse.

- Increased risk of overheating: Proper water levels are crucial for regulating the temperature of the battery. When the water levels are low, the battery is more prone to overheating, which can cause damage to the battery and pose a safety risk to operators.

Given these potential issues, it becomes clear that properly watering forklift batteries is essential for maintaining warehouse efficiency, productivity, and safety. So, how can you ensure that you are watering your forklift batteries correctly? Let’s dive into some helpful tips:

1. Check Water Levels Regularly

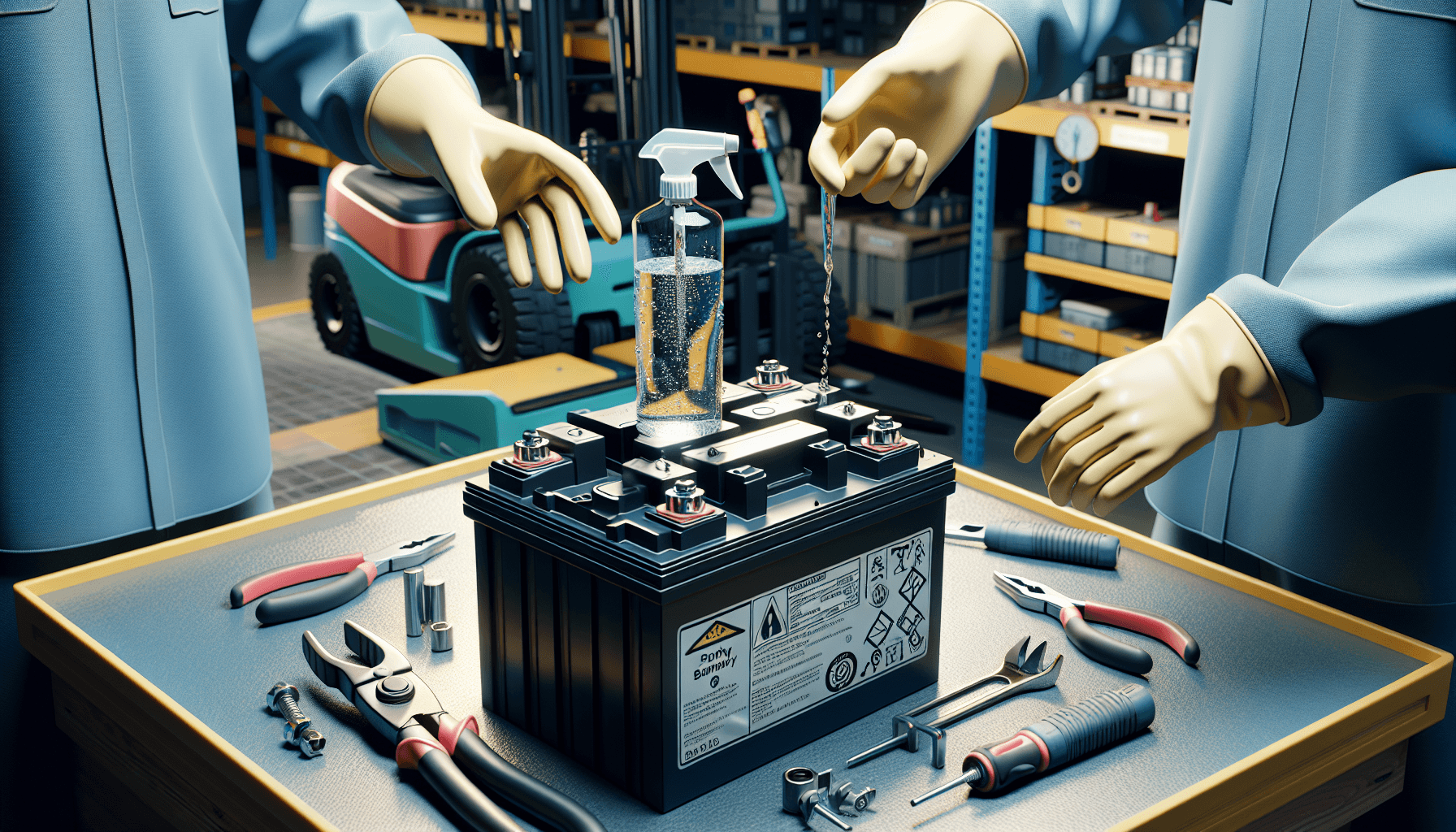

It’s important to regularly check the water levels in your forklift batteries. This should ideally be done at least once a week or more frequently if your forklifts are in heavy use. Open the battery compartment carefully and inspect the water levels in each cell. The water levels should cover the top of the battery plates, but not exceed the recommended levels.

2. Use Distilled Water

When adding water to your forklift batteries, always use distilled water. Tap water contains minerals and impurities that can damage the battery over time. Distilled water ensures that the battery is receiving pure water without any contaminants.

3. Add Water After Charging

It’s best to add water to the forklift battery after it has been fully charged. This helps prevent acid splashing during the charging process and allows you to gauge the correct water levels more accurately.

4. Fill Cells Individually

Filling each cell of the forklift battery individually ensures that the water is evenly distributed. Use a watering gun or a specific watering system designed for forklift batteries to make the process easier and more efficient.

5. Avoid Overfilling

While it’s important to maintain adequate water levels, overfilling the forklift battery can also be detrimental. Overfilling can lead to electrolyte overflow, which can damage the battery, surrounding components, and potentially create safety hazards. Follow the battery manufacturer’s guidelines for the recommended water levels.

By following these tips, you can ensure that your forklift batteries are properly watered, maximizing their performance and lifespan. Investing in a comprehensive forklift fleet power management solution can also greatly assist in maintaining optimal battery health. HCO Innovations offers innovative warehouse optimization solutions, including forklift fleet power management, that can help you streamline battery maintenance and ensure safe and efficient warehouse operations. To learn more about the benefits of forklift fleet power management, visit HCO Innovations.