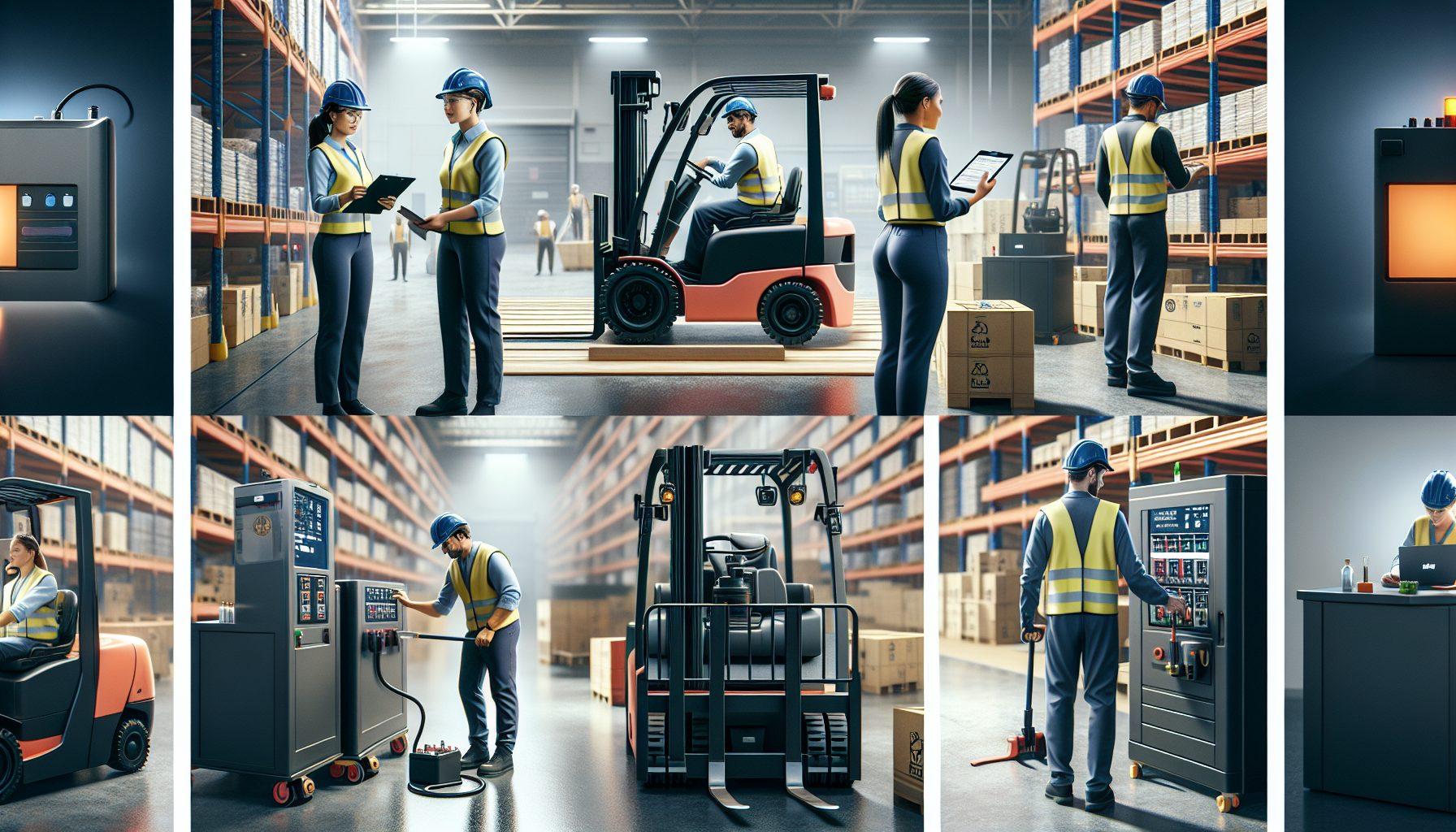

When it comes to running a warehouse, maximizing productivity and efficiency are key. One important aspect of warehouse operations that often gets overlooked is the management of forklift batteries. Forklifts are essential for moving goods within the warehouse, and ensuring that their batteries are properly maintained and optimized is crucial for keeping operations running smoothly.

The Importance of Forklift Battery Best Practices

Implementing forklift battery best practices can have a significant impact on the overall performance and cost-effectiveness of your warehouse operations. By following these practices, you can improve safety, extend battery life, increase productivity, and reduce repair and replacement costs.

1. Battery Inspection and Maintenance

Regular inspection and maintenance of forklift batteries is essential to ensure optimal performance. This includes:

- Checking the battery electrolyte levels and topping up with distilled water as needed.

- Cleaning the battery terminals and connectors to prevent corrosion.

- Inspecting the battery case for any signs of damage or leakage.

- Monitoring battery charging and discharging parameters to avoid overcharging or deep discharging.

By performing these routine tasks, you can prevent potential issues and prolong the lifespan of your forklift batteries.

2. Efficient Battery Charging

Proper charging is crucial for maintaining the health of forklift batteries. Here are some tips for efficient battery charging:

- Follow the manufacturer’s guidelines for charging times and voltages.

- Avoid interrupting the charging process as it can negatively impact the battery’s performance.

- Use smart chargers that have features like auto-shutoff to prevent overcharging.

- Implement a battery rotation system to ensure that batteries are evenly used and charged.

Efficient battery charging not only extends battery life but also reduces energy consumption and costs.

3. Monitoring and Data Analysis

Advancements in technology have made it easier than ever to monitor and analyze forklift battery performance. Implementing a battery management system can provide valuable insights into battery health and usage patterns. This data can help you identify areas for improvement and optimize battery usage.

At HCO Innovations, we offer forklift fleet power management solutions that can help streamline battery monitoring and data analysis. Our advanced software and hardware solutions allow you to track battery performance, identify inefficiencies, and make data-driven decisions to optimize your warehouse operations. Learn more here.

4. Training and Education

Another important aspect of implementing forklift battery best practices is ensuring that your employees are properly trained on battery maintenance and safety procedures. Providing comprehensive training programs can help reduce the risk of accidents and costly mistakes. It is important to educate your employees about the importance of following best practices and provide them with the necessary tools and knowledge to carry out their tasks efficiently.

Conclusion

Implementing forklift battery best practices is an integral part of optimizing warehouse operations. By prioritizing battery inspection and maintenance, efficient charging, monitoring, and data analysis, as well as training and education, you can enhance safety, productivity, and cost-effectiveness within your warehouse.

At HCO Innovations, we understand the importance of forklift battery optimization for warehouse operations. Contact us today to learn more about our forklift fleet power management solutions and how we can help you improve your warehouse efficiency here.