When it comes to warehouse operations, optimal performance is crucial for businesses to stay competitive and maximize their profitability. One essential aspect of warehouse operations is the management of the forklift fleet. Forklifts play a vital role in material handling and logistics within the warehouse, and their performance directly impacts overall efficiency and cost-effectiveness.

The Importance of Forklift Fleet Performance Metrics

By monitoring and analyzing forklift fleet performance metrics, warehouse managers can identify areas for improvement, make informed decisions, and implement effective strategies to optimize their operations. These performance metrics provide valuable insights into the productivity, safety, and maintenance requirements of the forklift fleet.

One of the key benefits of tracking forklift fleet performance metrics is the ability to identify and address inefficiencies. With accurate data on metrics such as productivity, utilization, and downtimes, warehouse managers can identify bottlenecks, reduce idle time, and increase throughput. This optimization of operations leads to improved overall efficiency and productivity.

Another important aspect of monitoring forklift fleet performance metrics is safety. Forklift operations can be hazardous if not properly managed. By tracking metrics related to safety incidents, near misses, and operator compliance, warehouse managers can identify areas of concern and take proactive measures to address them. This helps create a safer working environment for employees, minimizing the risk of accidents and injuries.

Furthermore, monitoring forklift fleet performance metrics helps businesses achieve cost savings. By analyzing metrics such as fuel consumption, maintenance costs, and equipment utilization, warehouse managers can identify opportunities to reduce expenses. For example, if certain forklifts consistently require more maintenance, it may indicate the need for preventive maintenance or replacement. This proactive approach can save costs in the long run by preventing breakdowns and expensive repairs.

In addition to cost savings, optimizing forklift fleet performance also contributes to environmental sustainability. By monitoring metrics such as fuel consumption and emissions, warehouse managers can identify opportunities to reduce carbon footprint and promote eco-friendly practices. For instance, by replacing older forklift models with newer, energy-efficient ones, businesses can minimize their environmental impact while also reducing fuel costs.

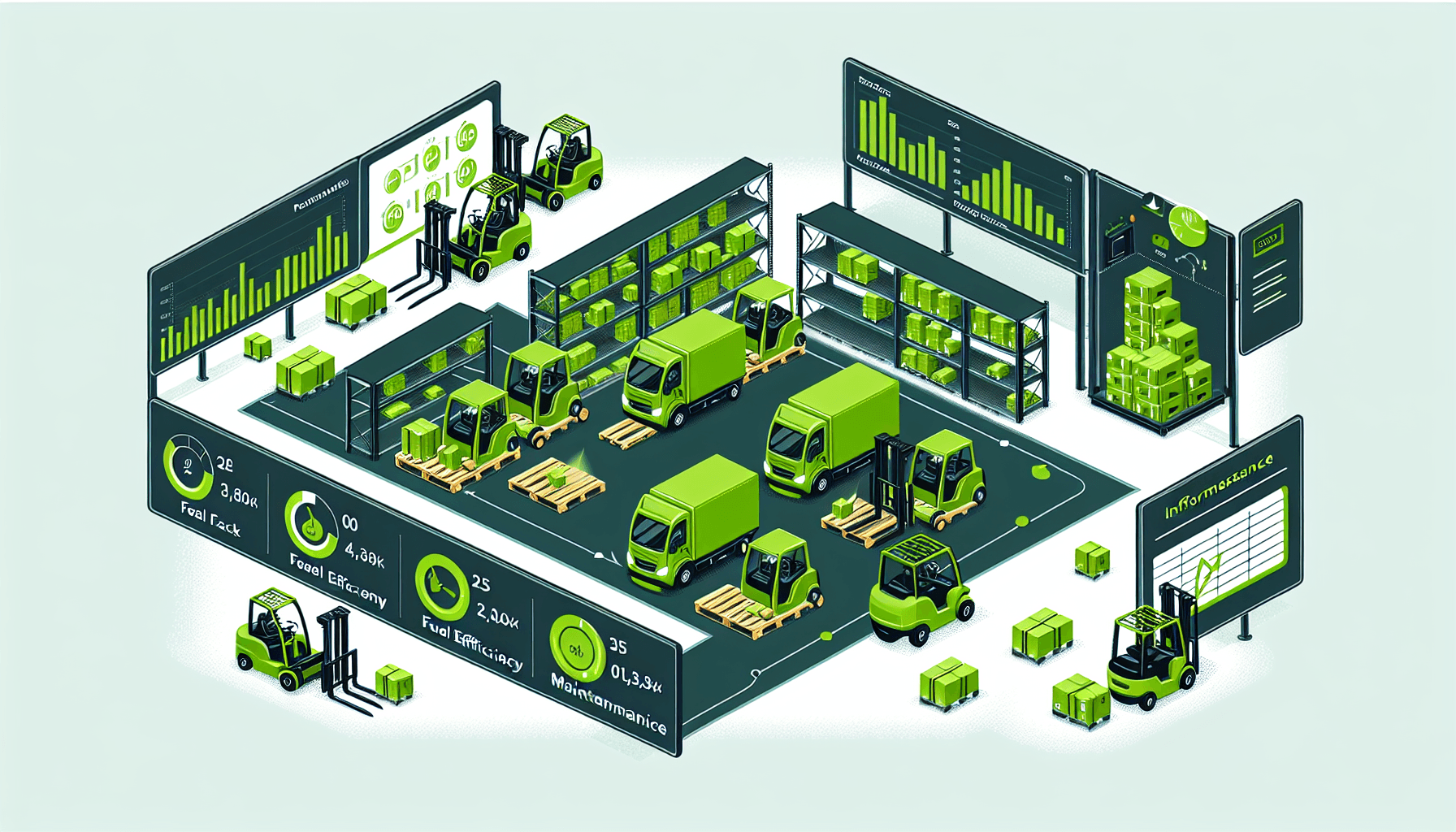

One effective way to track and manage forklift fleet performance metrics is through the use of advanced fleet management systems. These systems collect real-time data on various metrics, such as vehicle utilization, maintenance needs, and operator performance. The data is then analyzed and presented in easy-to-understand dashboards and reports, allowing warehouse managers to make data-driven decisions.

Forklift fleet management solutions offered by HCO Innovations are designed to help organizations optimize their forklift fleet performance. With their expertise in warehouse optimization, HCO Innovations provides innovative solutions that enhance safety, productivity, efficiency, and cost-effectiveness within warehouse operations.

Conclusion

Efficient management of the forklift fleet is crucial for achieving optimal performance, cost savings, and safety in warehouse operations. By monitoring and analyzing forklift fleet performance metrics, businesses can identify areas for improvement and implement strategies to enhance productivity, reduce costs, and ensure a safer working environment. Investing in advanced fleet management systems, such as those offered by HCO Innovations, can provide valuable insights and enable businesses to make data-driven decisions for better overall warehouse performance.