When it comes to warehouse operations, one of the key components that plays a crucial role in productivity and efficiency is Material Handling Equipment (MHE). From forklifts and pallet jacks to conveyors and automated systems, MHE is essential for the smooth functioning of a warehouse. However, managing and maintaining MHE can be costly and challenging for businesses. In this article, we will discuss how to implement a cost reduction plan for MHE to optimize your warehouse operations and improve the bottom line.

1. Assess Your Current MHE Fleet

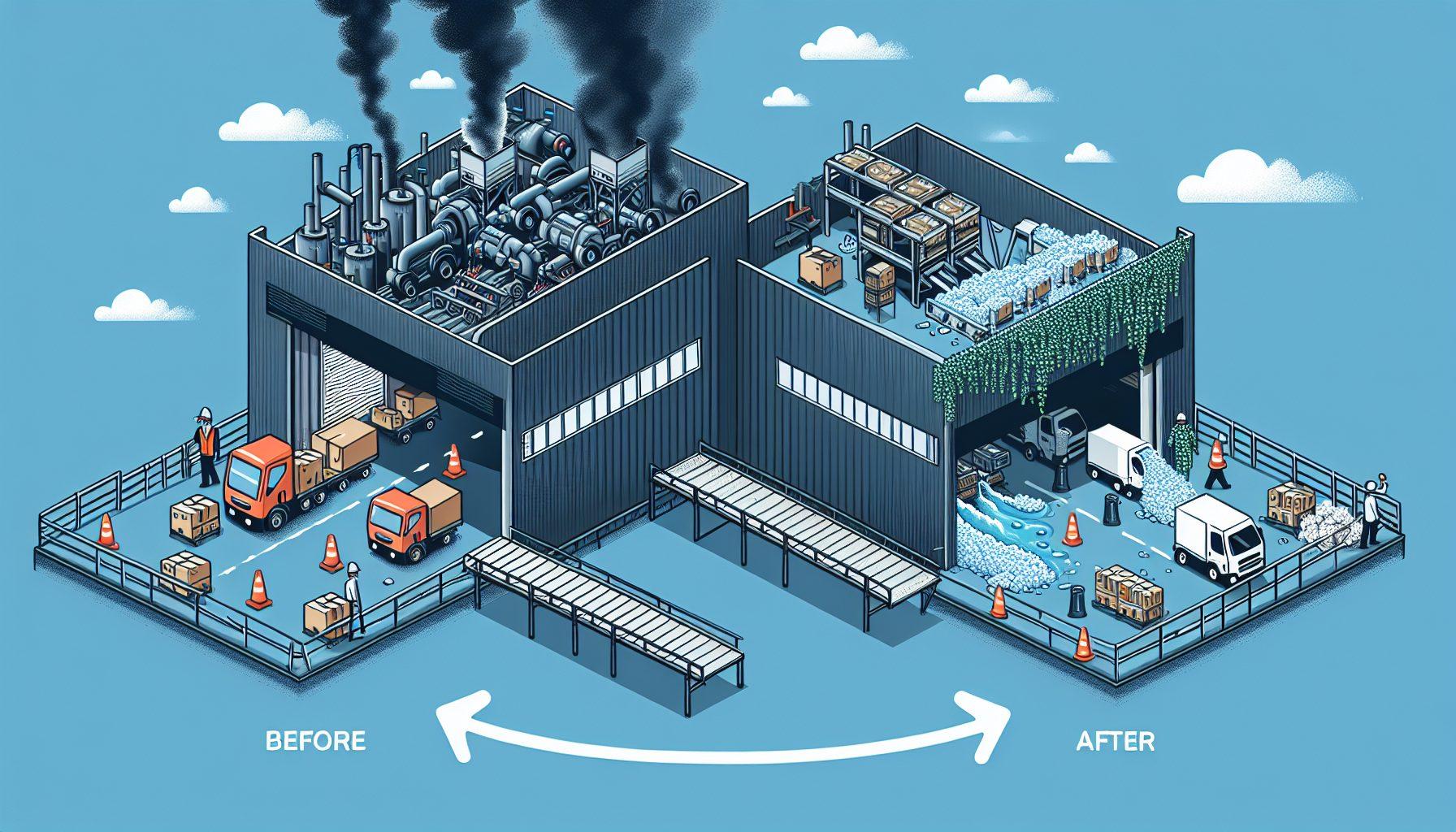

The first step in implementing a cost reduction plan for MHE is to assess your current fleet. Take stock of all the equipment you have in your warehouse and evaluate its condition, age, and performance. Identify any outdated or inefficient equipment that may be costing you more in repairs and maintenance. Consider replacing or upgrading these machines with newer, more energy-efficient models that require less maintenance. By streamlining your MHE fleet and eliminating underperforming equipment, you can reduce costs and improve overall productivity.

2. Regular Maintenance and Inspections

Regular maintenance and inspections are crucial for keeping your MHE fleet in optimal condition. Establish a comprehensive maintenance schedule that includes routine check-ups, preventive maintenance tasks, and timely repairs. This will help identify any potential issues before they escalate into major problems, minimizing downtime and costly repairs. Implementing a proactive maintenance strategy can extend the lifespan of your equipment and reduce the need for frequent replacements.

3. Training and Education

Investing in proper training and education for your warehouse staff can significantly impact the efficiency and safe operation of MHE. Provide your employees with comprehensive training programs that cover equipment operation, safety protocols, and best practices. Well-trained operators are less likely to cause accidents or damage to the equipment, reducing the risk of costly repairs and insurance claims. Additionally, educated personnel can optimize the use of MHE and increase productivity, leading to cost savings in the long run.

4. Implement Warehouse Management System (WMS)

A Warehouse Management System (WMS) is an essential tool for optimizing warehouse operations and reducing costs. This software solution helps automate and streamline various tasks, such as inventory management, order fulfillment, and equipment utilization. By integrating a WMS into your operations, you can track and manage MHE usage more effectively, minimizing idle time and maximizing productivity. Additionally, a WMS can provide real-time data and insights into your warehouse operations, enabling better decision-making and resource allocation.

5. Optimize Warehouse Layout and Workflow

The layout and workflow within your warehouse can have a significant impact on the efficiency and cost of MHE operations. Analyze your current layout and identify any bottlenecks or inefficient areas that may be causing delays and increasing equipment usage. Consider redesigning the layout to optimize the flow of goods and minimize unnecessary movement of MHE. Implementing efficient picking routes and utilizing automation where possible can help reduce labor costs and optimize the utilization of MHE.

6. Embrace Technology and Automation

Advancements in technology have revolutionized warehouse operations, and leveraging automation can provide significant cost savings in MHE management. Explore options for implementing automated systems such as conveyor belts, robotic pickers, and automated guided vehicles (AGVs). These technologies can help streamline processes, reduce manual labor, and increase overall efficiency. Additionally, implementing technologies like IoT sensors and predictive maintenance software can help monitor equipment health and proactively address maintenance needs, reducing downtime and repair costs.

7. Seek Expert Guidance

Implementing a cost reduction plan for MHE can be complex, and seeking expert guidance can be beneficial. Consult with a warehouse optimization specialist like HCO Innovations, who can provide valuable insights and tailored solutions based on your specific requirements. They have a wealth of experience in warehouse optimization and offer a range of services, including material handling equipment management, process improvement, and safety enhancements. Their expertise can help you identify areas for cost savings and implement strategies to optimize your warehouse operations.

In conclusion, implementing a cost reduction plan for MHE is crucial for optimizing your warehouse operations and improving the bottom line. By assessing your current fleet, implementing regular maintenance, providing training and education, utilizing warehouse management systems, optimizing layout and workflow, embracing technology and automation, and seeking expert guidance, you can effectively reduce costs associated with MHE management. Start implementing these strategies today and reap the benefits of a more efficient and cost-effective warehouse operation.

For more information on material handling equipment management solutions, visit HCO Innovations.