Are you looking for ways to reduce wear and tear on your Material Handling Equipment (MHE) to save on costs? Look no further! HCO Innovations is here to provide you with valuable insights and strategies on how to minimize MHE wear and tear and maximize your cost savings.

Importance of Reducing MHE Wear and Tear

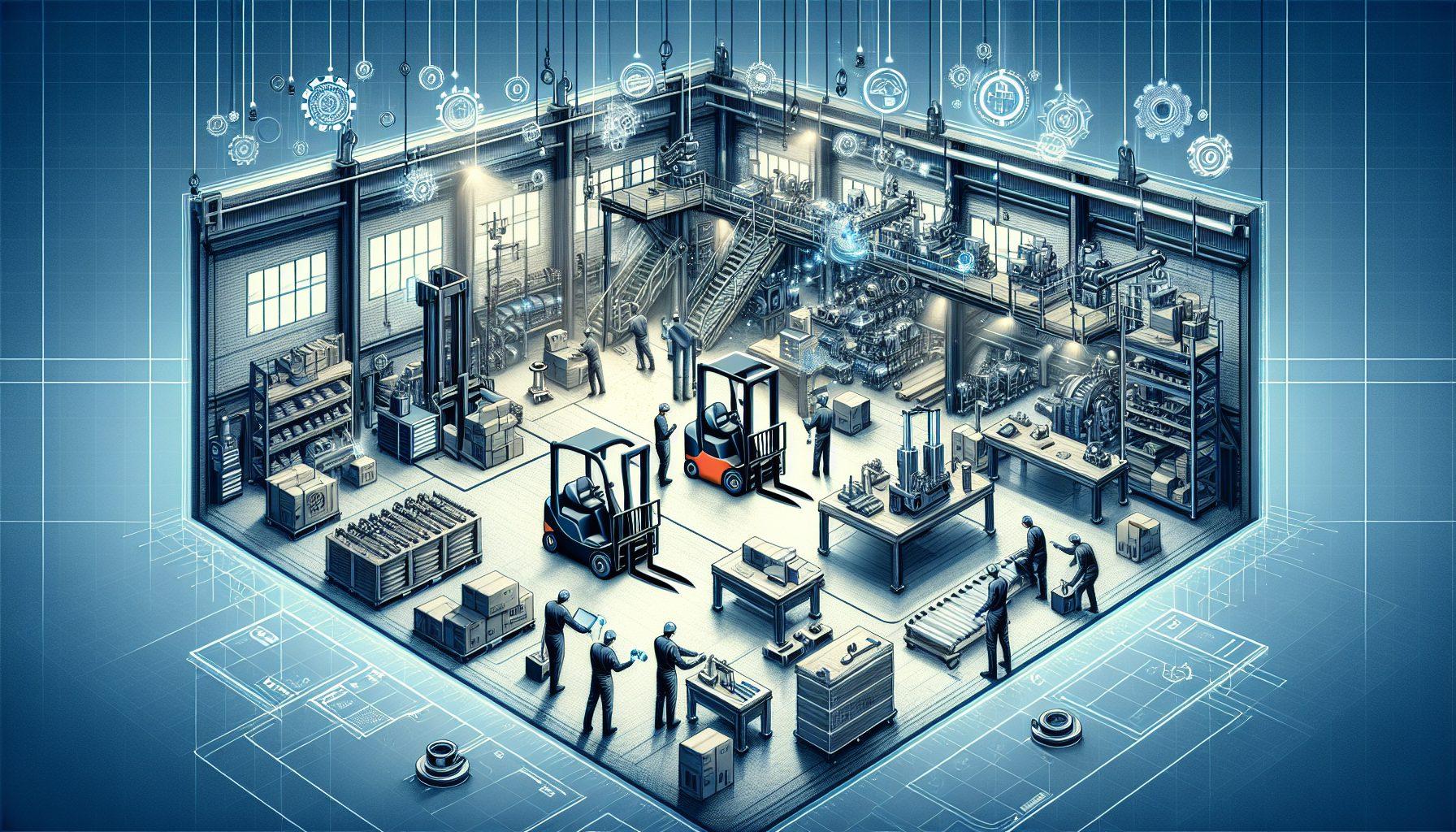

Material Handling Equipment plays a crucial role in the smooth functioning of warehouse operations. From forklifts to conveyors, these equipment are essential for transporting, storing, and organizing goods within a warehouse. However, constant usage and wear can lead to increased maintenance costs, downtime, and even equipment failure.

By implementing effective strategies to reduce MHE wear and tear, you can not only extend the lifespan of your equipment but also enhance safety, productivity, and efficiency within your warehouse operations. Let’s explore some key techniques to achieve this.

Regular Maintenance and Inspections

Regular maintenance and inspections are critical in preventing unnecessary wear and tear on your MHE. Develop a proactive maintenance schedule that includes routine inspections, lubrication, and component replacements as needed. By identifying and addressing minor issues before they escalate, you can significantly reduce the risk of equipment breakdown and prolong its lifespan.

Consider partnering with a reliable MHE services provider like HCO Innovations who can provide comprehensive maintenance and inspection programs tailored to your specific equipment needs.

Training and Education

Another key aspect of reducing MHE wear and tear is ensuring that your operators are well-trained and educated on proper equipment usage and maintenance. Proper training not only enhances operational efficiency but also minimizes the risk of accidents and damage to the equipment.

HCO Innovations offers training programs that focus on safe handling techniques, preventive maintenance, and equipment troubleshooting. Investing in operator training can go a long way in reducing wear and tear on your MHE while improving the overall efficiency of your warehouse operations.

Optimizing Workflows and Layouts

The layout and workflow within your warehouse can have a significant impact on MHE wear and tear. Poorly designed layouts can result in unnecessary distance traveled, excessive maneuvering, and increased stress on the equipment.

Consider implementing warehouse optimization solutions offered by HCO Innovations to design efficient workflows and layouts. By analyzing your current operations, they can identify bottlenecks, optimize pick paths, and reduce unnecessary movements, ultimately reducing wear and tear on your MHE.

Investing in Quality Equipment

The quality of your MHE plays a vital role in its durability and resistance to wear and tear. Investing in reliable equipment from reputable manufacturers can save you money in the long run by reducing maintenance and repair costs.

HCO Innovations can assist you in selecting the right MHE for your warehouse needs. They offer a wide range of high-quality, durable equipment that is specially designed for efficient and safe warehouse operations.

Whether you need forklifts, pallet jacks, or automated guided vehicles (AGVs), HCO Innovations has got you covered.

Utilizing Technology to Minimize Wear and Tear

Advancements in technology have revolutionized warehouse operations, providing innovative solutions to minimize wear and tear on MHE. Implementing technologies like predictive maintenance systems and asset tracking can help you identify potential issues before they cause significant damage.

Consider integrating MHE management systems provided by HCO Innovations, which allow you to monitor the performance and condition of your equipment in real-time. These systems can automatically schedule preventive maintenance, track usage patterns, and provide valuable insights to optimize equipment utilization.

In conclusion, reducing MHE wear and tear is crucial for cost savings and operational efficiency. By implementing regular maintenance, providing training to operators, optimizing workflows, investing in quality equipment, and utilizing technology solutions, you can minimize downtime, extend the lifespan of your MHE, and ultimately save costs.

If you are looking for expert assistance in managing your MHE efficiently and reducing wear and tear, partner with HCO Innovations. Visit their website for more information on material handling equipment management and how their solutions can benefit your warehouse operations.

Learn more about HCO Innovations’ material handling equipment management solutions here.