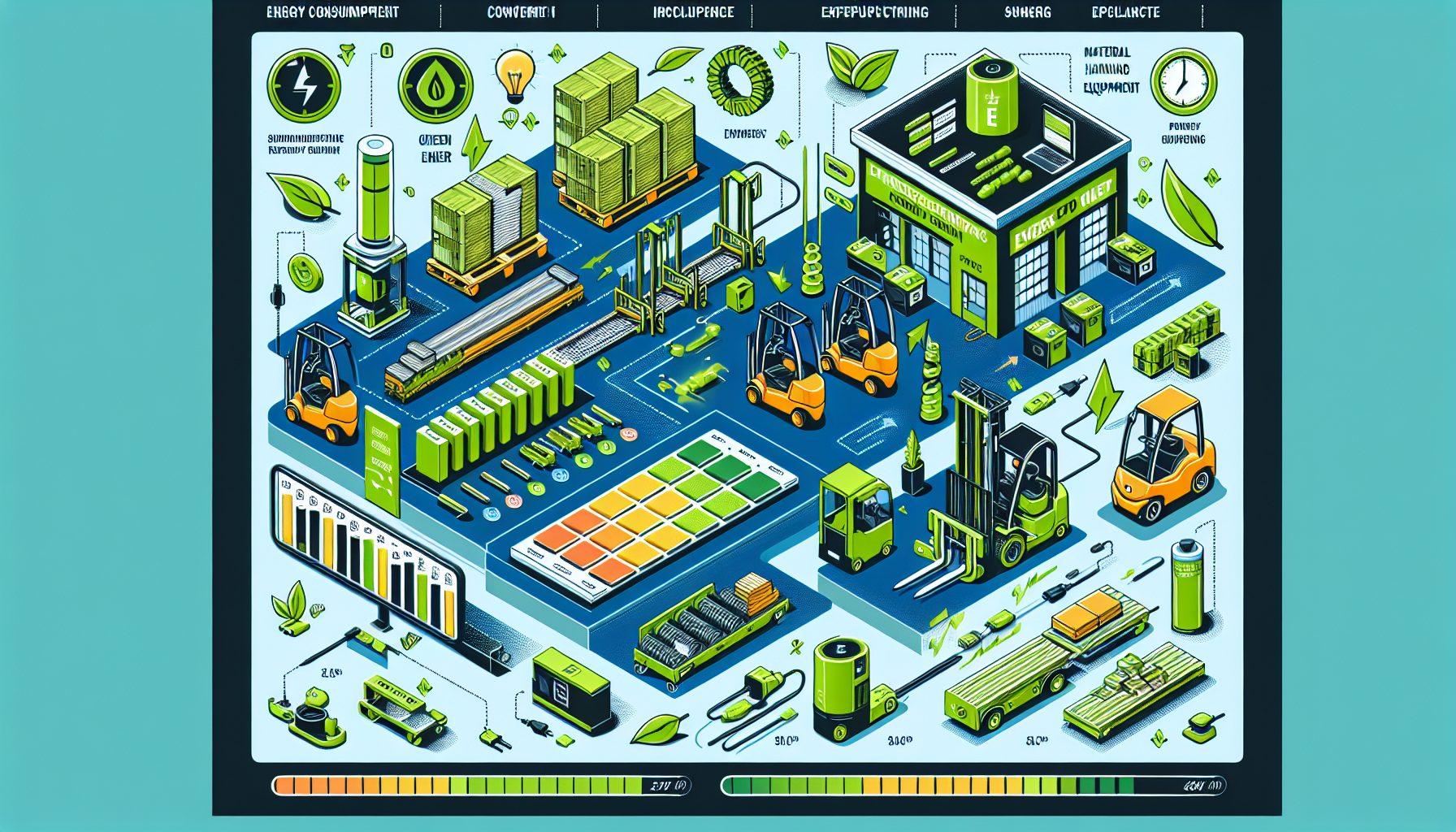

Managing energy consumption within a warehouse is a crucial aspect of optimizing operations and reducing costs. One area of focus when it comes to energy consumption is Material Handling Equipment (MHE). By adopting energy-efficient practices and technologies, warehouse operators can effectively manage MHE energy consumption and achieve significant cost savings.

The Importance of Managing MHE Energy Consumption

In a bustling warehouse environment, MHE plays a vital role in ensuring smooth operations and efficient movement of goods. However, MHE also consumes a significant amount of energy, which can result in high operational costs. Managing MHE energy consumption is essential for several reasons:

- Cost Optimization: By actively managing MHE energy consumption, warehouse operators can identify areas with higher energy consumption and implement measures to optimize efficiency, leading to cost savings.

- Sustainability: Reducing energy consumption aligns with sustainable practices, helping warehouse operations minimize their environmental impact.

- Productivity: Optimizing MHE energy consumption ensures that energy resources are efficiently utilized, resulting in improved productivity and performance.

- Equipment Lifespan: Efficient energy management practices can extend the lifespan of MHE by reducing wear and tear caused by excessive energy usage.

Now, let’s explore some effective strategies to manage MHE energy consumption for cost savings:

1. Conduct Energy Audits

Prior to implementing any energy-saving initiatives, it is crucial to conduct an energy audit of the warehouse facility. An energy audit helps identify areas of excessive energy consumption and pinpoint potential energy-saving opportunities.

During the energy audit, warehouse operators should assess the efficiency of MHE, including forklifts, conveyors, and automated systems. They should also analyze lighting systems, HVAC (Heating, Ventilation, and Air Conditioning), and other aspects that contribute to overall energy consumption.

Based on the audit findings, warehouse operators can develop a tailored energy management plan that targets specific areas for improvement.

2. Invest in Energy-Efficient Equipment

Replacing outdated and energy-intensive MHE with energy-efficient alternatives is a significant step towards managing energy consumption. Consider investing in equipment that is designed to optimize energy usage and improve overall efficiency.

For example, electric forklifts are an energy-efficient alternative to traditional internal combustion forklifts. They generate no emissions and consume less energy, resulting in long-term cost savings.

Warehouse optimization solutions providers like HCO Innovations offer a range of energy-efficient MHE options that can help warehouse operators decrease energy consumption and achieve cost savings. Their expertise and knowledge in warehouse operations make them a reliable partner for businesses seeking to improve energy efficiency.

3. Implement Energy Management Systems

Energy management systems (EMS) are tools specifically designed to monitor and optimize energy consumption within a warehouse. These systems collect and analyze real-time data to identify areas of excessive energy usage and provide insights for improving efficiency.

With an EMS, warehouse operators can track energy consumption patterns over time, detect anomalies, and implement appropriate measures to reduce energy waste. These systems often include features like smart sensors, automated controls, and energy usage reports for proactive energy management.

4. Optimize Warehouse Layout

The layout of a warehouse can greatly impact energy consumption. By optimizing the warehouse layout, warehouse operators can minimize unnecessary movements and streamline processes, leading to energy savings.

Consider organizing the warehouse in a way that minimizes travel distances for MHE. Group frequently accessed items together and place them near the shipping area to reduce unnecessary movement and energy consumption.

Additionally, strategic placement of lighting fixtures can improve visibility while minimizing power usage. Incorporating skylights or natural lighting sources can also reduce the need for artificial lighting.

5. Implement Employee Training Programs

Warehouse employees play a crucial role in managing energy consumption. By providing comprehensive training programs, warehouse operators can educate employees about energy-saving practices and encourage their active participation in energy conservation efforts.

Training programs can cover topics such as proper MHE operation techniques, energy-efficient handling procedures, and the importance of turning off equipment when not in use. Engaging employees in energy-saving initiatives fosters a culture of sustainability and ensures continuous improvement in energy management.

6. Regular Maintenance and Monitoring

Regular maintenance and monitoring of MHE are essential for optimal energy management. Warehouse operators should schedule routine maintenance checks to ensure equipment is functioning efficiently and to identify any potential energy-related issues.

Monitoring energy usage patterns and analyzing data collected from energy meters and other monitoring devices can also provide insights into areas that require further optimization. Identifying and addressing energy inefficiencies promptly can result in significant cost reductions.

Conclusion

Managing MHE energy consumption is critical for warehouse operators aiming to optimize operations, reduce costs, and contribute to sustainable practices. By conducting energy audits, employing energy-efficient equipment, implementing energy management systems, optimizing warehouse layouts, providing employee training, and conducting regular maintenance and monitoring, warehouse operators can effectively manage MHE energy consumption and achieve significant cost savings.

HCO Innovations is a trusted provider of warehouse optimization solutions, offering a range of energy-efficient MHE options. Their expertise and commitment to enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations make them an ideal partner for businesses seeking to manage MHE energy consumption and achieve cost savings.