In today’s fast-paced warehouse environment, businesses are constantly looking for ways to optimize their operations and reduce overhead costs. One of the key factors that can significantly impact both efficiency and cost-effectiveness is the utilization of Material Handling Equipment (MHE). Effective management of MHE can have a direct impact on reducing overhead costs and maximizing productivity.

The Importance of MHE in Warehouse Operations

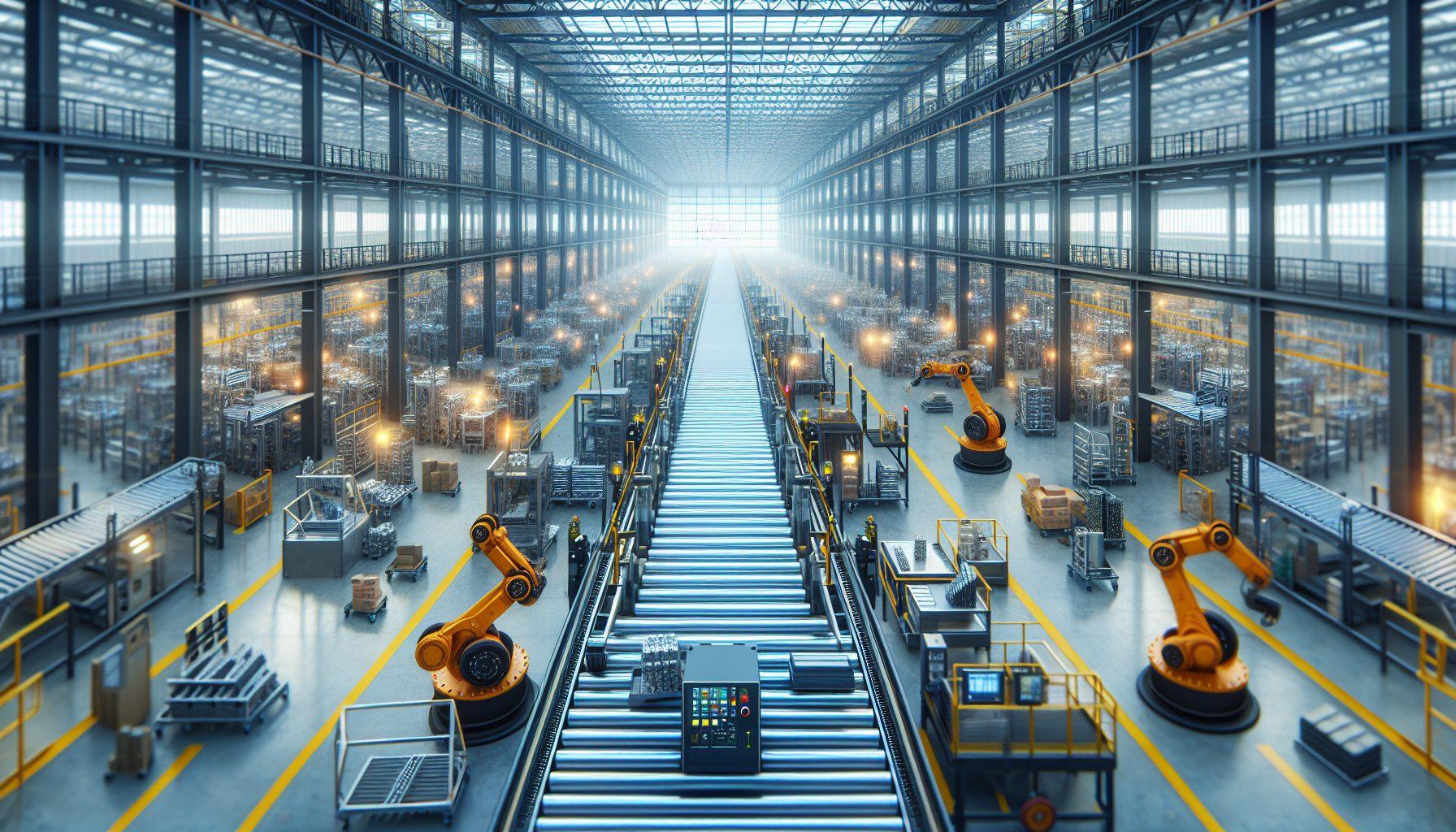

Material Handling Equipment plays a vital role in warehouse operations, facilitating the movement, storage, and handling of goods and materials. This includes equipment such as forklifts, pallet jacks, conveyors, and automated systems. These machines streamline operations and enable faster, more efficient handling of products, which directly impacts the overall productivity and profitability of the warehouse.

With the advancements in technology, modern MHE systems offer a range of features that can significantly enhance safety, productivity, and efficiency within the warehouse. HCO Innovations, a prominent provider of warehouse optimization solutions, specializes in helping businesses leverage the full potential of MHE to optimize their operations.

Reducing Overhead Costs with MHE

One of the biggest benefits of effectively managing MHE is its ability to reduce overhead costs. By implementing the right equipment and utilizing them efficiently, warehouses can streamline their processes and minimize wastage, leading to significant cost savings. Here are some ways MHE can help reduce overhead costs:

1. Improved Efficiency

Efficient handling and movement of materials significantly increase productivity and reduce labor costs. By utilizing MHE like forklifts and conveyors, warehouses can minimize manual handling, minimize errors, and complete tasks in less time. This translates into higher efficiency, increased throughput, and reduced labor expenses.

2. Enhanced Safety Measures

MHE is designed with safety features that aim to minimize accidents and injuries in the warehouse. By incorporating these safety measures into your operations, you can reduce the risk of workplace accidents, worker compensation claims, and related costs. Additionally, ensuring proper training and certification for employees operating MHE can help prevent mishaps and improve overall safety.

3. Optimal Space Utilization

MHE can help warehouses optimize their use of available space. For instance, vertical conveyor systems and high reaching forklifts enable businesses to store goods vertically, maximizing the use of warehouse height. By making the most of the available space, warehouses can reduce the need for additional storage facilities or warehouse expansion, saving costs in the long run.

4. Reduced Product Damage

Mishandling or improper storage can result in product damage, leading to financial losses. However, by utilizing MHE like automated guided vehicles (AGVs) and robotic systems, warehouses can ensure gentle and precise handling of products, significantly minimizing the chances of damage. This, in turn, reduces the need for costly product replacements and repair.

5. Streamlined Inventory Management

Efficient inventory management is crucial for minimizing carrying costs and ensuring accurate stock levels. MHE systems equipped with barcode scanning, RFID technology, and inventory management software enable real-time tracking and accurate inventory control. This helps reduce stock-outs, overstocking, and inventory losses, leading to improved cost-effectiveness.

HCO Innovations offers comprehensive MHE management solutions that address all aspects of warehouse optimization. With their expertise, businesses can achieve significant cost savings while enhancing productivity and efficiency.

Conclusion

Effectively managing Material Handling Equipment is vital for reducing overhead costs and maximizing the efficiency of warehouse operations. By leveraging advanced MHE systems and solutions, businesses can streamline processes, enhance safety, optimize space utilization, reduce product damage, and streamline inventory management. With the expertise and solutions provided by HCO Innovations, companies can unlock the full potential of MHE and achieve cost-effectiveness within their warehouse operations.

For more information about material handling equipment management, visit HCO Innovations.