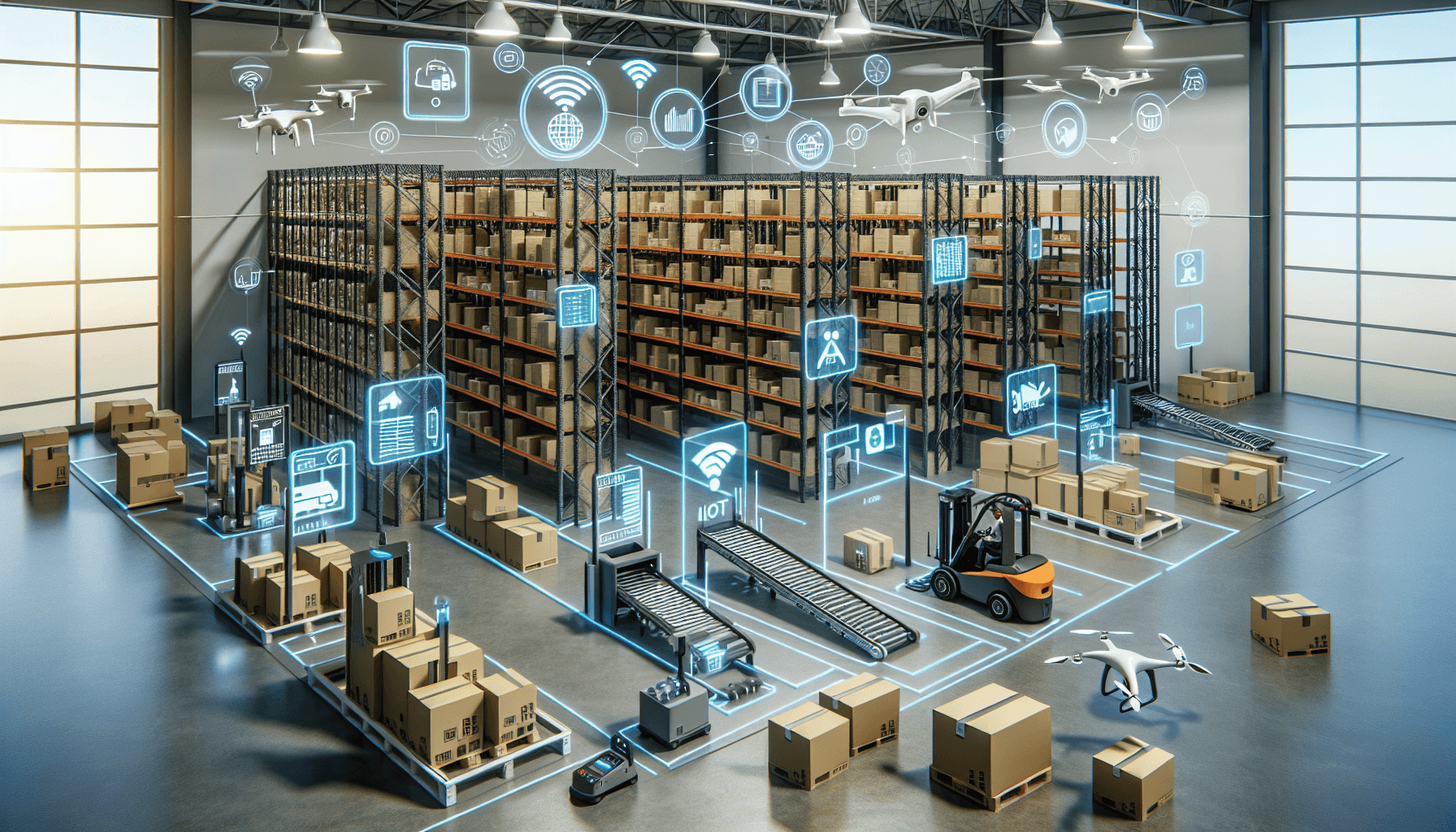

When it comes to warehouse operations, cost efficiency is key. Maximizing productivity while minimizing expenses can greatly impact the profitability of a business. In today’s digital age, one technology that has revolutionized the way warehouses operate is the Internet of Things (IoT). In this article, we will explore the role of IoT in enhancing warehouse cost efficiency and how companies like HCO Innovations are utilizing IoT solutions to optimize warehouse operations.

Improving Inventory Management with IoT

One of the biggest challenges in warehouse operations is maintaining accurate inventory levels. Manual inventory tracking methods are prone to human error, leading to discrepancies and inefficiencies. With IoT, warehouses can automate the inventory management process, leading to improved accuracy and efficiency.

IoT devices such as RFID tags and sensors can be placed on products and shelves, allowing for real-time tracking of inventory. These devices can automatically monitor stock levels, track the movement of goods, and send alerts when inventory levels are low. This not only reduces the risk of stockouts but also helps businesses avoid overstocking, which can tie up valuable resources and increase carrying costs.

Additionally, IoT-enabled inventory management systems can integrate with other software solutions such as enterprise resource planning (ERP) systems, enabling seamless data exchange and providing valuable insights into inventory trends, demand patterns, and lead times. These insights empower warehouses to make data-driven decisions and optimize inventory levels, reducing holding costs and improving overall cost efficiency.

Enhancing Operational Visibility

Warehouse operations involve a multitude of activities, from receiving and storing goods to picking, packing, and shipping orders. Ensuring optimal workflow and minimizing delays is crucial for cost efficiency. IoT plays a significant role in enhancing operational visibility, enabling warehouses to monitor and optimize various aspects of their operations.

By leveraging IoT devices such as connected sensors, cameras, and GPS trackers, warehouses can gain real-time visibility into inventory movement, equipment performance, and overall workflow. For example, temperature and humidity sensors can monitor environmental conditions in storage areas to prevent spoilage and damage to perishable goods. GPS trackers integrated with fleet management systems can track the location and route optimization of delivery vehicles, reducing fuel costs and improving delivery time.

Moreover, IoT solutions can also enable predictive maintenance by collecting data on the performance and condition of equipment such as forklifts, conveyor belts, and automated storage and retrieval systems (AS/RS). This data can be analyzed to detect potential issues or failures before they occur, allowing for proactive maintenance and minimizing costly downtime.

Optimizing Energy Usage

Energy costs can make up a significant portion of warehouse expenses. IoT offers opportunities to optimize energy usage and reduce costs through smart energy management solutions.

IoT-enabled energy management systems can monitor and control lighting, heating, cooling, and other energy-consuming devices in real-time. For example, motion sensors can detect activity in specific areas of the warehouse and automatically adjust lighting levels or HVAC settings accordingly. This ensures that energy is only consumed when and where it is needed, reducing unnecessary energy usage and lowering utility bills.

Furthermore, IoT devices can collect data on energy usage patterns, allowing for the identification of areas where energy efficiency improvements can be made. Warehouses can then implement measures such as installing energy-efficient lighting systems, optimizing insulation, or upgrading equipment to more energy-efficient models.

Streamlining Supply Chain Management

Efficient supply chain management is crucial for warehouse cost efficiency. IoT solutions can enhance visibility, traceability, and collaboration across the supply chain, leading to streamlined operations and reduced costs.

For example, RFID technology combined with IoT enables the tracking and tracing of goods throughout the entire supply chain. This real-time visibility helps warehouses optimize receiving, storage, and shipping processes, reducing errors, and improving efficiency.

Moreover, IoT devices can facilitate communication and data exchange between different stakeholders in the supply chain, including suppliers, manufacturers, distributors, and retailers. This seamless integration improves collaboration, enables better forecasting and planning, and reduces lead times. By eliminating manual communication and automating processes, warehouses can achieve significant time and cost savings.

In Conclusion

The Internet of Things is revolutionizing warehouse operations and playing a crucial role in enhancing cost efficiency. From improving inventory management to enhancing operational visibility, optimizing energy usage, and streamlining supply chain management, IoT solutions are enabling warehouses to become more productive, efficient, and cost-effective.

HCO Innovations is at the forefront of utilizing IoT solutions to optimize warehouse operations. Their expertise in warehouse cost analysis and implementation of IoT-enabled solutions has helped numerous businesses achieve significant cost savings and operational improvements. To learn more about how HCO Innovations can help your warehouse maximize cost efficiency, click here.