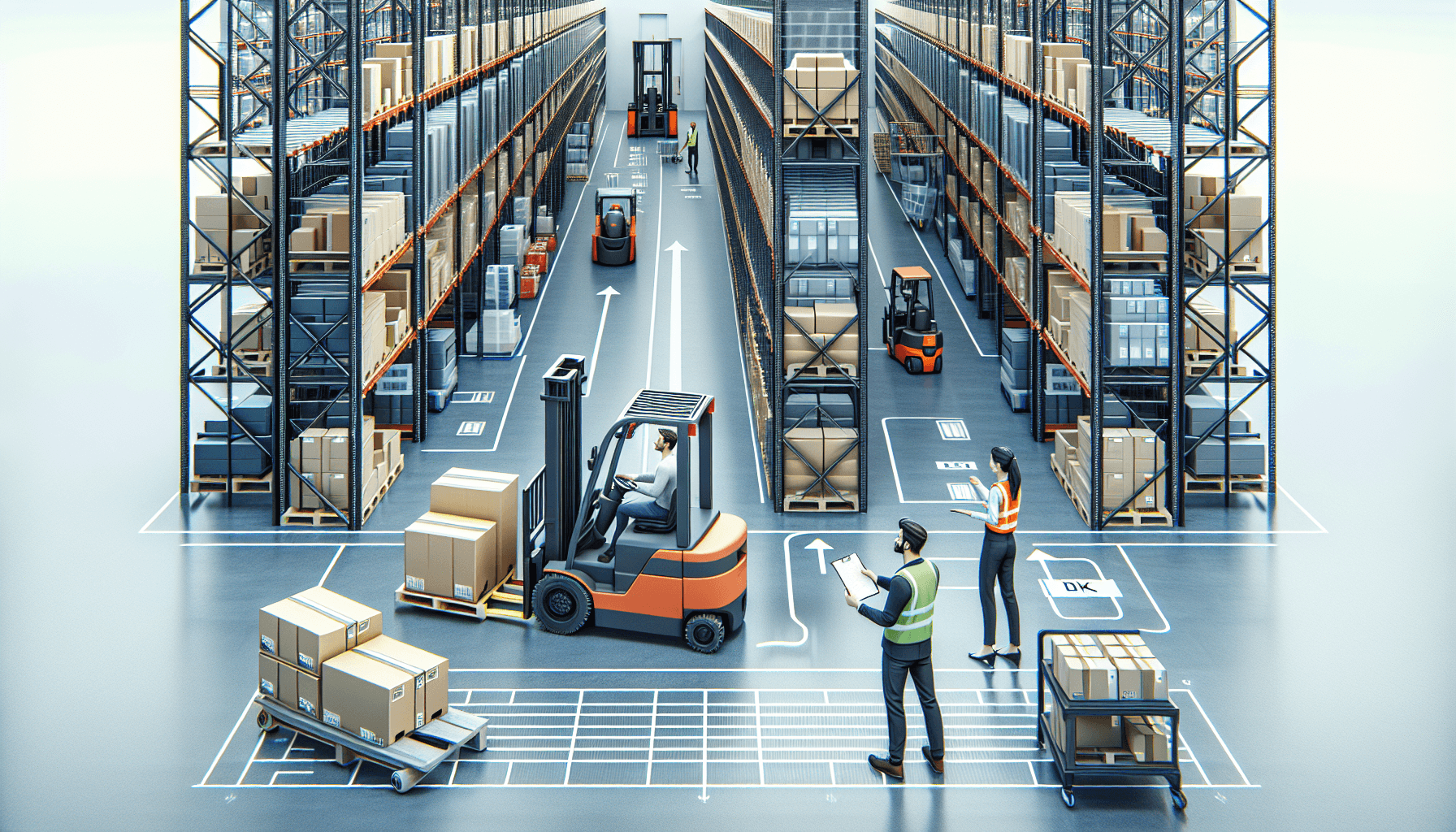

When it comes to warehouse operations, optimizing your warehouse layout is crucial. A well-optimized warehouse layout can significantly improve safety, productivity, efficiency, and cost-effectiveness. One key aspect of warehouse layout optimization is optimizing pallet storage. In this article, we will explore different strategies and best practices to optimize your warehouse layout specifically for pallet storage.

1. Analyze your current warehouse layout

The first step in optimizing your warehouse layout for pallet storage is to analyze your current setup. Evaluate how your pallets are currently stored and identify any areas for improvement. This could include inefficient use of space, overcrowding, or lack of organization.

Warehouse layout evaluation can help you gain insights into your current setup. By working with professionals who specialize in warehouse optimization, you can identify the strengths and weaknesses of your current layout and develop a plan for improvement.

2. Utilize vertical space

When it comes to pallet storage, utilizing vertical space is key. Many warehouses have high ceilings that aren’t fully utilized. Consider implementing taller storage racks or mezzanines to maximize vertical storage capacity. This can help free up valuable floor space while still allowing easy access to your inventory.

Additionally, consider investing in equipment such as forklifts or reach trucks that can safely and efficiently reach higher shelves. This will enable you to store more pallets vertically without sacrificing accessibility.

3. Implement proper labeling and organization

Proper labeling and organization play a crucial role in optimizing pallet storage. Clear and consistent labeling allows for easy identification and tracking of inventory. Implement a standardized labeling system that includes information such as product code, quantity, and location.

Organize your pallets based on factors such as product type, popularity, or expiration date to optimize picking and retrieval processes. Consider implementing color-coded systems or barcode scanning technology to streamline inventory management.

4. Optimize aisle width

The width of your aisles can greatly impact the efficiency of your warehouse operations. Narrower aisle widths can maximize storage capacity but may limit accessibility and maneuverability. On the other hand, wider aisles may be necessary for larger equipment or high-traffic areas.

Analyze your inventory and equipment needs to determine the appropriate aisle width for each section of your warehouse. Consider utilizing different aisle width configurations based on the type of products and storage systems being used.

5. Implement a FIFO (First-In, First-Out) system

For warehouses dealing with perishable or time-sensitive goods, implementing a FIFO system is vital. This system ensures that older inventory is used or shipped out before newer items, reducing the risk of product spoilage or obsolescence.

Designate specific areas or shelves for incoming pallets and implement a clear rotation policy. This will help ensure that the oldest pallets are always in the front and are the first to be picked or shipped.

6. Invest in warehouse management software

Warehouse management software can greatly facilitate the optimization of your warehouse layout for pallet storage. These software solutions offer features such as inventory tracking, order management, and real-time reporting.

By implementing a capable warehouse management system, you can streamline operations, improve accuracy, and reduce costs. It will provide you with valuable insights into your inventory levels, space utilization, and overall warehouse performance.

7. Regularly review and adjust your layout

Warehouse optimization is an ongoing process. It’s crucial to regularly review and adjust your layout to accommodate changes in inventory, customer demand, or operational requirements.

Conduct routine audits to identify any inefficiencies or bottlenecks in your pallet storage system. Seek feedback from your warehouse staff and consider their suggestions for improvement. This will help you continuously optimize your warehouse layout and stay ahead of evolving business needs.

In conclusion, optimizing your warehouse layout for pallet storage is essential for warehouse efficiency and cost-effectiveness. By analyzing your current layout, utilizing vertical space, implementing proper labeling and organization, optimizing aisle width, implementing a FIFO system, investing in warehouse management software, and regularly reviewing and adjusting your layout, you can create a well-optimized warehouse that maximizes pallet storage capacity while ensuring easy accessibility and efficient operations.

Ready to evaluate and optimize your warehouse layout? Contact HCO Innovations today to learn more about our warehouse optimization solutions!