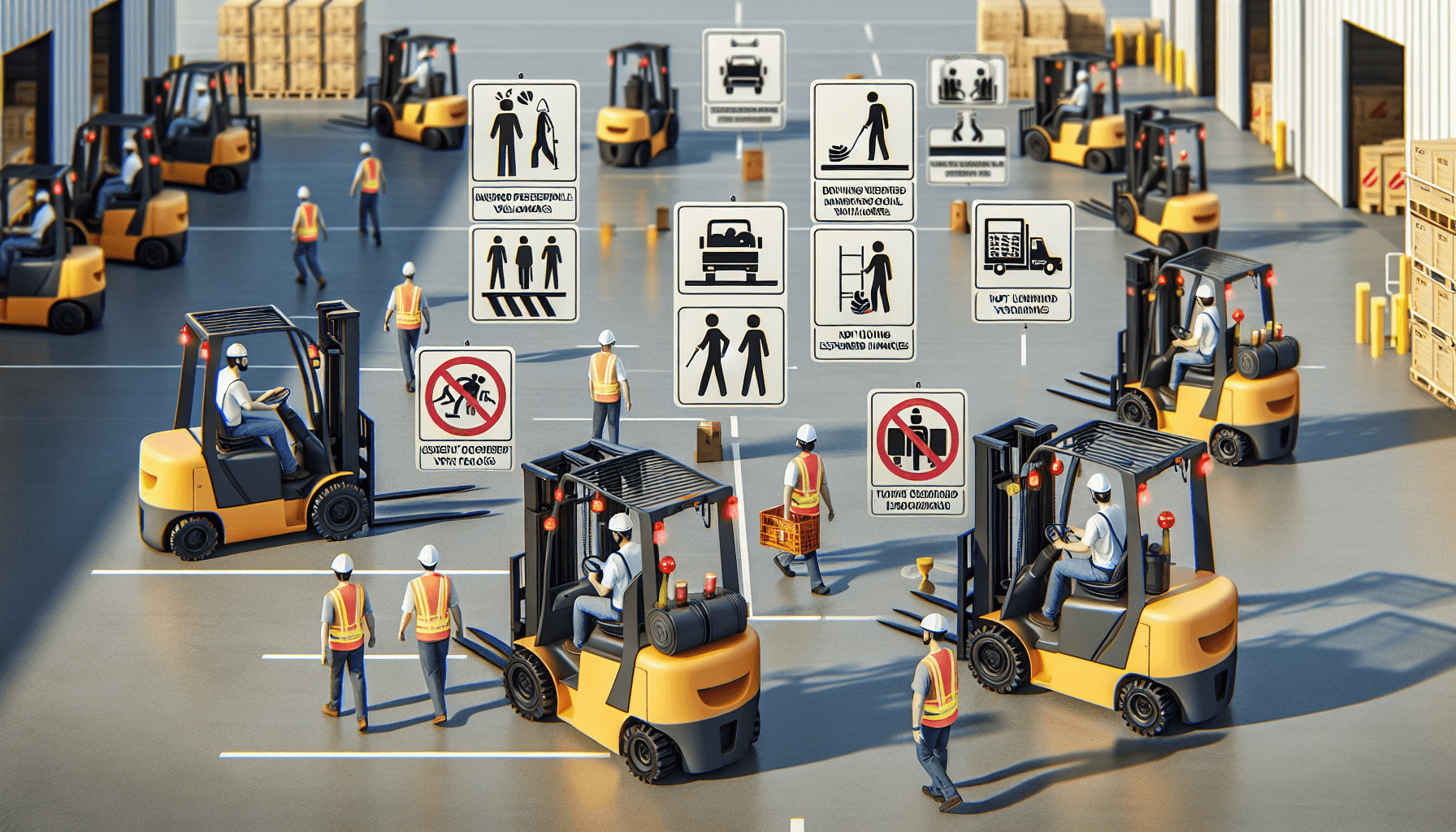

Forklifts are a critical part of warehouse operations, enabling the safe and efficient movement of goods. However, without proper adherence to forklift safety guidelines, accidents can happen, posing a risk to both employees and equipment. In this article, we will discuss some of the common forklift safety violations that occur in warehouse settings and provide guidance on how to address them.

1. Failure to Provide Adequate Training and Certification

One of the most common forklift safety violations is the failure to provide employees with proper training and certification. Operating a forklift requires specialized skills and knowledge to ensure the safe handling of materials. Without adequate training, forklift operators may not be aware of important safety measures or may not be proficient in maneuvering the equipment.

To address this violation, it is crucial for warehouse managers to prioritize comprehensive forklift training programs. This includes classroom instruction on safety protocols, hands-on practice sessions, and evaluations to assess an operator’s proficiency. Additionally, it is essential to ensure that all forklift operators hold valid certifications, demonstrating their ability to operate the equipment safely.

At HCO Innovations, we understand the importance of forklift operator training and offer comprehensive training programs tailored to warehouse operations. With our warehouse safety evaluation, we can assess your current training protocols and develop customized training solutions to address any gaps and ensure compliance with safety regulations.

2. Lack of Regular Forklift Inspections and Maintenance

Another common forklift safety violation is the neglect of regular inspections and maintenance. Forklifts are subjected to daily wear and tear, and any malfunction or defects could lead to accidents. Failing to conduct routine inspections and maintenance increases the risk of equipment failure during operational use.

To address this violation, warehouse managers should implement a robust inspection and maintenance program for all forklifts. This includes daily pre-shift inspections, where operators check for any visible damage or malfunctions before starting work. Regular maintenance schedules should also be in place, with qualified technicians conducting thorough inspections, servicing, and repairs as needed.

At HCO Innovations, we provide warehouse optimization solutions, including maintenance management systems, that can help streamline the inspection and maintenance process for forklifts. Our systems allow you to schedule and track inspections, automate maintenance tasks, and generate reports to ensure compliance with safety regulations.

3. Ignoring Load Capacity Limits and Stability Concerns

Ignoring load capacity limits and stability concerns is another significant forklift safety violation. Overloading a forklift or improperly distributing the load can result in tip-overs, causing serious injuries to operators and potential damage to the goods being transported. It is crucial to follow load capacity guidelines and ensure proper load distribution for the safe operation of forklifts.

To address this violation, warehouse managers should emphasize the importance of adhering to load capacity limits and teach operators how to properly secure and distribute loads on the forklift. Operators should also be trained on how to assess load stability before moving the forklift and avoid sudden movements or sharp turns that may compromise the stability of the load.

At HCO Innovations, we offer warehouse optimization solutions that can help improve load management and enhance forklift stability. Our advanced technology solutions provide real-time load monitoring, offering valuable insights into load distribution and ensuring operators stay within safe load capacity limits.

4. Failure to Provide Adequate Traffic Management

Inadequate traffic management is another common forklift safety violation that can lead to accidents and near misses within a warehouse. With multiple forklifts and pedestrians moving in close proximity, it is essential to establish clear traffic routes and implement effective signage and markings to prevent collisions.

To address this violation, warehouse managers should conduct a thorough assessment of their traffic management strategy. This includes clearly marked pedestrian walkways, designated forklift lanes, and the use of mirrors and warning signs to alert both forklift operators and pedestrians to potential hazards. Regular training sessions should also be held to educate employees on safe traffic practices and the importance of staying alert in high-traffic areas.

At HCO Innovations, we specialize in warehouse optimization solutions, including traffic management systems. Our expertise in designing efficient traffic flow patterns and implementing advanced safety measures can help minimize the risk of collisions and enhance overall warehouse safety.

Conclusion

Addressing forklift safety violations is crucial to maintaining a safe and productive warehouse environment. By providing adequate training and certification, conducting regular inspections and maintenance, adhering to load capacity limits, and implementing effective traffic management strategies, warehouse managers can mitigate the risks associated with forklift operations.

At HCO Innovations, we are committed to helping warehouse operations optimize safety, productivity, and efficiency. With our comprehensive warehouse optimization solutions, including training programs, maintenance management systems, and traffic management systems, we can assist you in addressing forklift safety violations and creating a safer working environment for your employees.