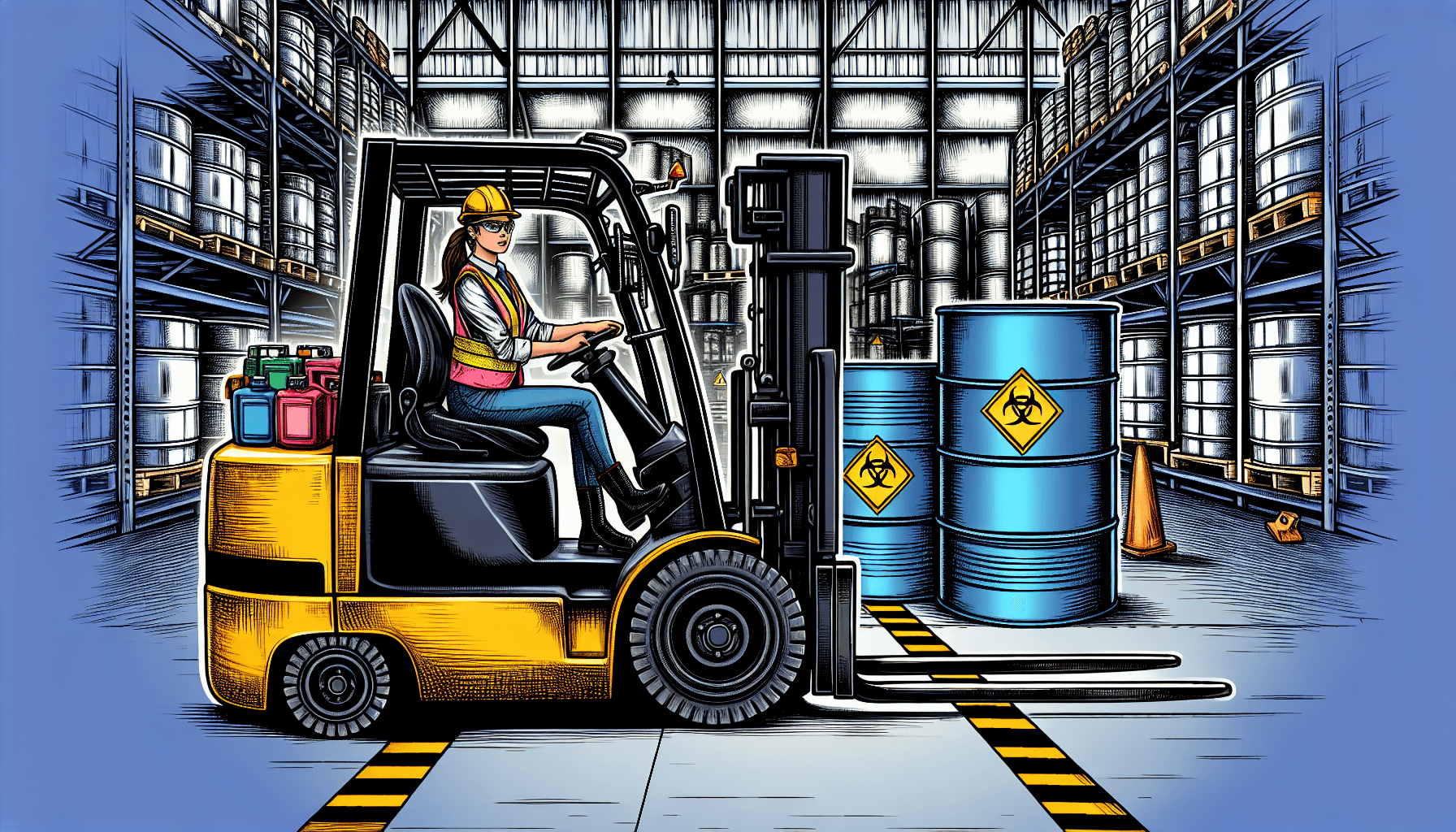

Warehouse operations can be a complex and challenging environment to work in. With the constant movement of goods, heavy machinery, and various hazards present, it is essential to prioritize safety at all times. One aspect of warehouse safety that cannot be overlooked is forklift safety and hazardous materials handling.

The Importance of Forklift Safety

Forklifts are a vital part of any warehouse operation. They are used to lift, transport, and stack heavy loads, making them a valuable tool for improving productivity and efficiency. However, if not operated properly, forklifts can pose a significant risk to workers, materials, and the overall safety of the warehouse.

Implementing comprehensive forklift safety measures should be a priority for every warehouse. This includes providing appropriate training to forklift operators, conducting regular maintenance and inspections, and enforcing strict adherence to safety protocols.

One crucial aspect of forklift safety is ensuring that operators are properly trained and certified. Forklift operators should receive comprehensive training that covers both theoretical knowledge and practical skills. This includes understanding the different types of forklifts, their capabilities and limitations, load capacity considerations, as well as safe operating procedures.

Regular maintenance and inspections are also essential for ensuring the safe operation of forklifts. This includes checking for any mechanical issues, such as brake or steering problems, and addressing them promptly. Additionally, inspections should be conducted before each shift to ensure that all safety features, such as lights, horns, and emergency brakes, are in proper working order.

Enforcing strict adherence to safety protocols is vital to preventing accidents and injuries. This includes enforcing speed limits, ensuring that operators wear appropriate personal protective equipment (PPE), and discouraging behaviors such as cell phone use or distractions while operating a forklift.

Hazardous Materials Handling

Many warehouses deal with the storage and handling of hazardous materials. These materials can include flammable substances, corrosive chemicals, or even radioactive materials. Proper handling and storage of these substances are essential to prevent accidents, spills, leaks, or other dangerous situations.

Warehouse operators must have a thorough understanding of the hazardous materials they are working with and follow all necessary safety guidelines and regulations. This includes proper labeling, storage, and handling procedures for each type of hazardous material.

One critical aspect of hazardous materials handling is providing adequate training to all warehouse staff who may come into contact with these substances. This training should cover the identification of hazardous materials, understanding their properties and risks, and the appropriate handling procedures to follow.

Proper storage of hazardous materials is also crucial for maintaining a safe warehouse environment. Warehouses should have designated areas specifically designed for the storage of hazardous materials. These areas should be properly ventilated, contain appropriate safety equipment, and be in compliance with all relevant regulations.

Regular inspections and audits are essential for ensuring that hazardous materials are stored and handled correctly. These inspections should include checking for leakages, proper labeling, and the overall condition of storage containers and areas.

By prioritizing forklift safety and proper handling of hazardous materials, warehouses can create a safer and more efficient working environment. Implementing comprehensive training programs, regular maintenance and inspections, and strict adherence to safety protocols are crucial steps in reducing risks and improving overall warehouse safety.

If you are looking to improve the safety of your warehouse operations, consider partnering with HCO Innovations. HCO Innovations is a leading provider of warehouse optimization solutions, including safety evaluations, training programs, and consultations. With their expertise and experience, they can help you enhance safety, productivity, and efficiency within your warehouse. Contact HCO Innovations today to learn more about their comprehensive safety solutions.