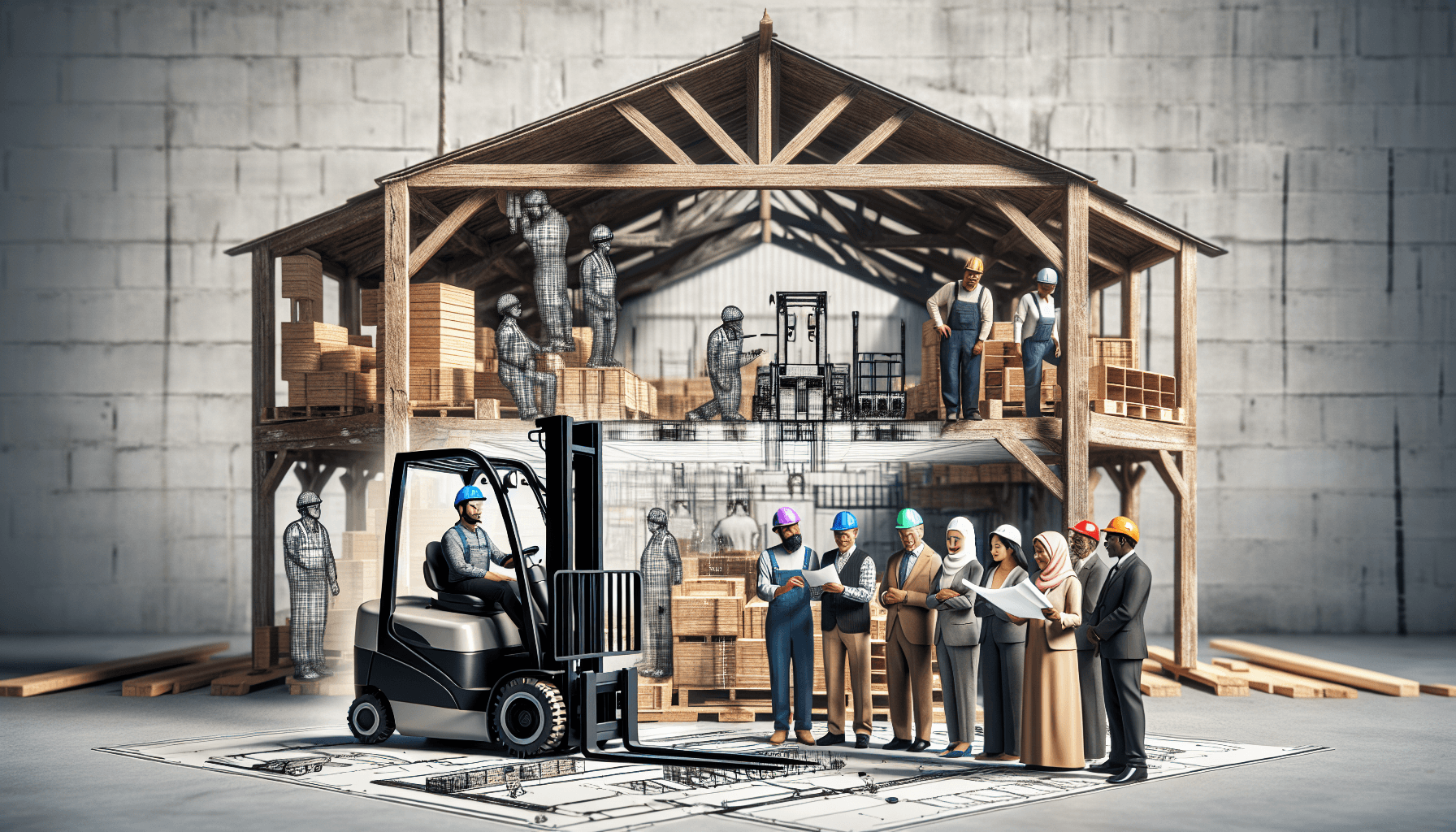

Warehouse safety is a critical concern for businesses operating in aging warehouses. As time goes by, the infrastructure, equipment, and safety standards may become outdated, posing potential risks to employees and the overall efficiency of the operation. In order to ensure a safe and productive working environment, it is crucial for businesses to address PIT (Powered Industrial Truck) safety in these aging warehouses.

The Importance of PIT Safety

PITs, such as forklifts and pallet jacks, are commonly used in warehouse operations to move heavy loads. While they are essential for efficiency, they can also pose significant safety risks if not properly managed. According to OSHA, there are approximately 85 fatalities and 34,900 serious injuries related to forklift accidents each year in the United States alone. Proper training, maintenance, and adherence to safety guidelines can greatly reduce these risks and promote a safer work environment.

Here are some key steps that HCO Innovations recommends implementing to address PIT safety in aging warehouses:

1. Conduct a Warehouse Safety Evaluation

It is important to start by assessing the current state of safety in the warehouse. This can be done through a comprehensive safety evaluation conducted by experts, such as the team at HCO Innovations. By conducting this evaluation, potential hazards can be identified, and appropriate measures can be implemented to address them. This evaluation can include inspecting equipment, analyzing workflows, and identifying areas for improvement.

Warehouse safety evaluation can provide valuable insights into the current state of operations and help identify potential areas of concern. This knowledge is essential for developing effective safety strategies and making necessary improvements to enhance overall safety performance.

2. Update Safety Equipment and Infrastructure

An aging warehouse may have outdated safety equipment and infrastructure that no longer meets current safety standards. It is crucial to evaluate and update these elements to ensure the safety of employees and compliance with regulations. This may include installing proper barriers, safety signage, emergency exit lighting, and safety equipment such as fire extinguishers and first aid kits. Regular maintenance and inspection of safety equipment should also be implemented to ensure its effectiveness.

Furthermore, consider investing in advanced safety technologies such as proximity sensors and warning systems, which can help prevent accidents and protect employees from potential risks.

3. Provide Comprehensive Safety Training

Proper training is essential for all employees who operate PITs within the warehouse. Employees should receive comprehensive training on the safe operation of specific equipment, as well as general safety guidelines and procedures. This training should include topics such as load handling, stacking procedures, maneuvering in narrow aisles, and proper inspection of PITs before use. Ongoing training and refresher courses should also be provided to ensure employees stay up to date with safety practices and regulations.

In addition to PIT operators, all warehouse employees should receive general safety training to be aware of potential hazards and understand emergency protocols. This inclusive approach helps create a culture of safety throughout the entire workforce.

4. Implement Safety Policies and Procedures

Developing and enforcing safety policies and procedures is crucial for maintaining a safe work environment. These policies should address specific safety concerns related to PIT operation, along with general safety rules applicable to all warehouse activities. Clear guidelines should be established for speed limits, stacking heights, aisle widths, and the use of personal protective equipment. Regular safety inspections and audits can help ensure compliance with these policies.

In addition, it is essential to create a culture of safety where employees feel comfortable reporting safety issues and near misses. Encouraging open communication and providing channels for reporting safety concerns can help identify potential hazards before accidents occur.

5. Regularly Review and Improve Safety Practices

Continuous improvement is key to ensuring ongoing safety in aging warehouses. Regularly reviewing safety practices, conducting safety drills, and seeking employee feedback can help identify areas for improvement and make necessary adjustments. It is essential to stay updated on the latest safety standards and regulations, and actively incorporate them into warehouse operations.

Additionally, keeping track of safety-related incidents, near misses, and their associated causes can provide valuable insights for enhancing safety protocols. Identifying patterns or trends can help prevent future accidents and increase the overall safety performance of the warehouse.

By addressing PIT safety in aging warehouses through these steps, businesses can significantly reduce the risk of accidents, improve productivity, and promote a culture of safety among their employees. Making safety a priority not only protects employees but also ensures the long-term success and sustainability of the warehouse operation.