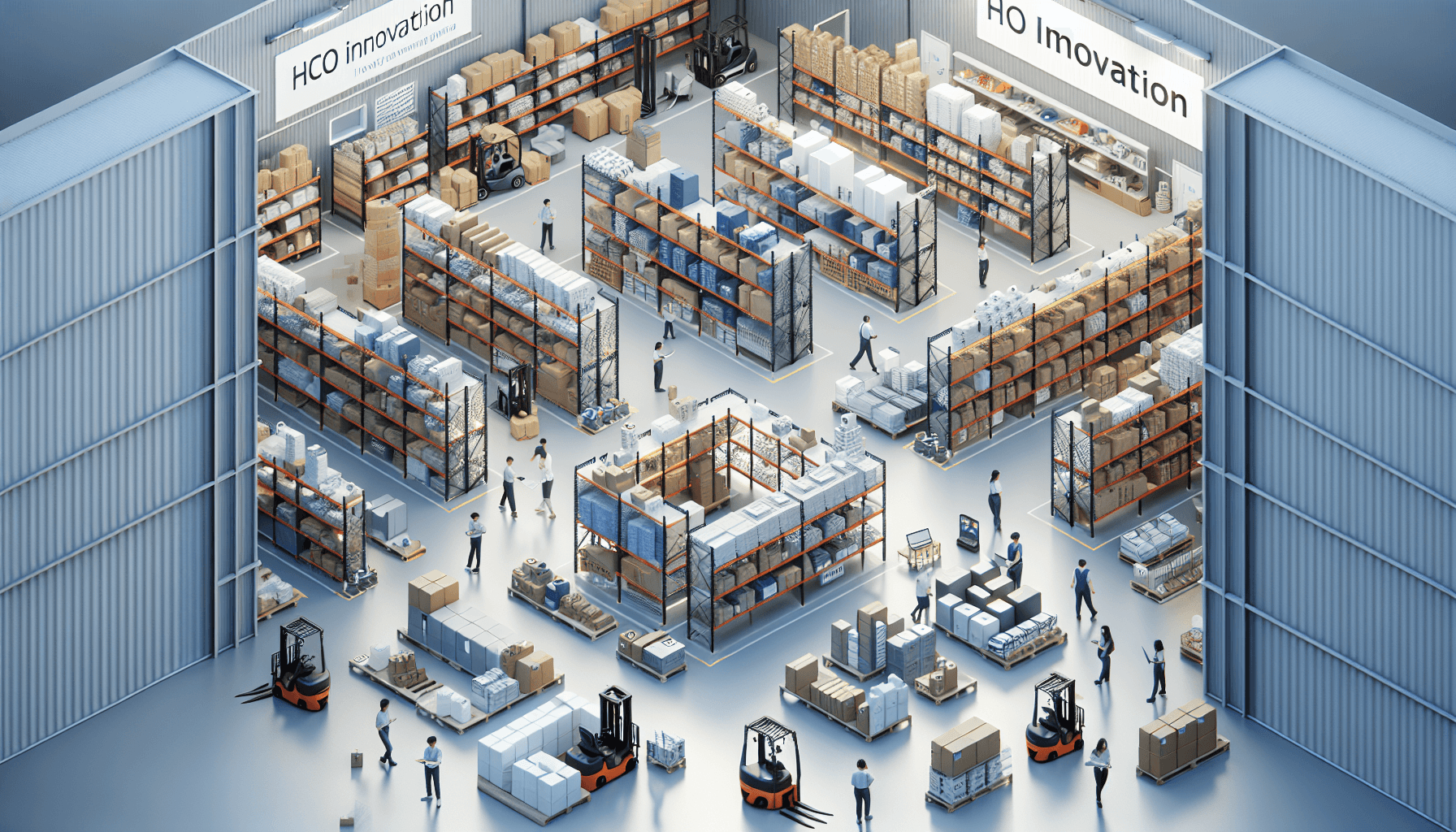

Creating an efficient warehouse layout is crucial for optimizing productivity and supporting multiple workflows. If your warehouse operations involve handling different types of products or fulfilling various orders, it’s essential to design a layout that allows for seamless movement and organization. In this article, we will share some valuable tips on how to create a warehouse layout that supports multiple workflows.

1. Understand Your Workflows

Before diving into designing your warehouse layout, it’s important to have a clear understanding of your workflows. Take the time to analyze your current processes, including receiving, storage, picking, packing, and shipping. Identify any bottlenecks or areas that can be improved.

Consider the different types of products you handle and their specific requirements. Are there different temperature zones or storage conditions needed? Are some products more fragile or have unique handling requirements? Understanding these details will help you design a layout that caters to the diverse needs of your workflows.

2. Optimize Space Utilization

Maximizing space utilization is a key aspect of creating an efficient warehouse layout. Consider both horizontal and vertical space. Use racking systems, mezzanines, and stacking techniques to make the most of the available space while ensuring easy accessibility.

Implement a systematic approach to categorize and organize your inventory. Utilize labeling, barcode scanning, and inventory management software to streamline the storage process. This will allow you to locate items quickly and reduce the time spent searching for products.

Additionally, consider implementing dynamic slotting strategies. Regularly analyze sales data and adjust the placement of frequently picked items to minimize travel time and improve overall picking efficiency.

3. Design Efficient Traffic Flow

Efficient traffic flow is critical for smooth operations within your warehouse. By designing clear pathways and separating different processes, you can minimize congestion and eliminate unnecessary cross-traffic.

Plan for separate receiving and shipping areas to prevent incoming and outgoing goods from interfering with each other. Use floor markings or signage to clearly indicate designated areas for specific workflows.

Consider implementing one-way traffic patterns to ensure a streamlined flow. This can be achieved by strategically placing designated aisles and pathways throughout the warehouse. Use barriers or guardrails to separate vehicle traffic from pedestrian walkways for enhanced safety.

4. Invest in Technology

Technology plays a vital role in optimizing warehouse operations. Consider implementing warehouse management systems (WMS) to improve inventory tracking, order fulfillment, and overall workflow management.

Utilize barcode scanning or RFID technology to streamline the picking process and reduce errors. This technology enables accurate and efficient item identification, ensuring the right products are picked for each order.

Enhance your warehouse layout with automation solutions such as conveyor systems, robotic picking systems, or automated retrieval systems. These technologies can significantly improve productivity and reduce manual labor requirements, allowing you to handle multiple workflows more efficiently.

5. Continuous Improvement and Flexibility

Creating a warehouse layout that supports multiple workflows is an ongoing process. Regularly evaluate and analyze your workflow efficiency to identify areas for improvement. Seek feedback from your employees and incorporate their insights for enhancing the layout.

Stay flexible and adapt your layout as your business needs evolve. As your product line expands or order volumes increase, consider reconfiguring your warehouse layout to accommodate these changes.

Remember that warehouse optimization is not a one-time task. It requires continuous monitoring, tweaking, and investment in new technologies as they become available. By staying proactive in your approach, you can create a warehouse layout that supports multiple workflows and drives overall operational success.

For a professional evaluation of your warehouse layout and optimization needs, contact HCO Innovations. We specialize in providing warehouse optimization solutions tailored to your specific requirements, ensuring enhanced safety, productivity, efficiency, and cost-effectiveness within your warehouse operations.