Designing a warehouse for the seamless operation of Automated Guided Vehicles (AGVs) is crucial for maximizing efficiency, productivity, and safety. AGVs are becoming increasingly popular in warehouse operations due to their ability to automate material transport and reduce manual labor. To ensure smooth AGV operations, it is essential to carefully plan and design the warehouse layout, infrastructure, and systems. In this article, we will explore key considerations and best practices for designing a warehouse for AGV operations.

1. Analyze Warehouse Requirements

Before designing a warehouse for AGV operations, it is important to assess the specific requirements and goals of the facility. This includes analyzing factors such as the type and volume of products to be stored, the flow of goods within the warehouse, and desired throughput rates. Understanding these requirements will help in determining the optimal layout, storage systems, and AGV configurations.

Additionally, it is essential to evaluate the existing infrastructure, including the size and layout of the building, column positions, floor conditions, and ceiling heights. This analysis will help identify any constraints or modifications required for AGV integration.

2. Optimize Warehouse Layout

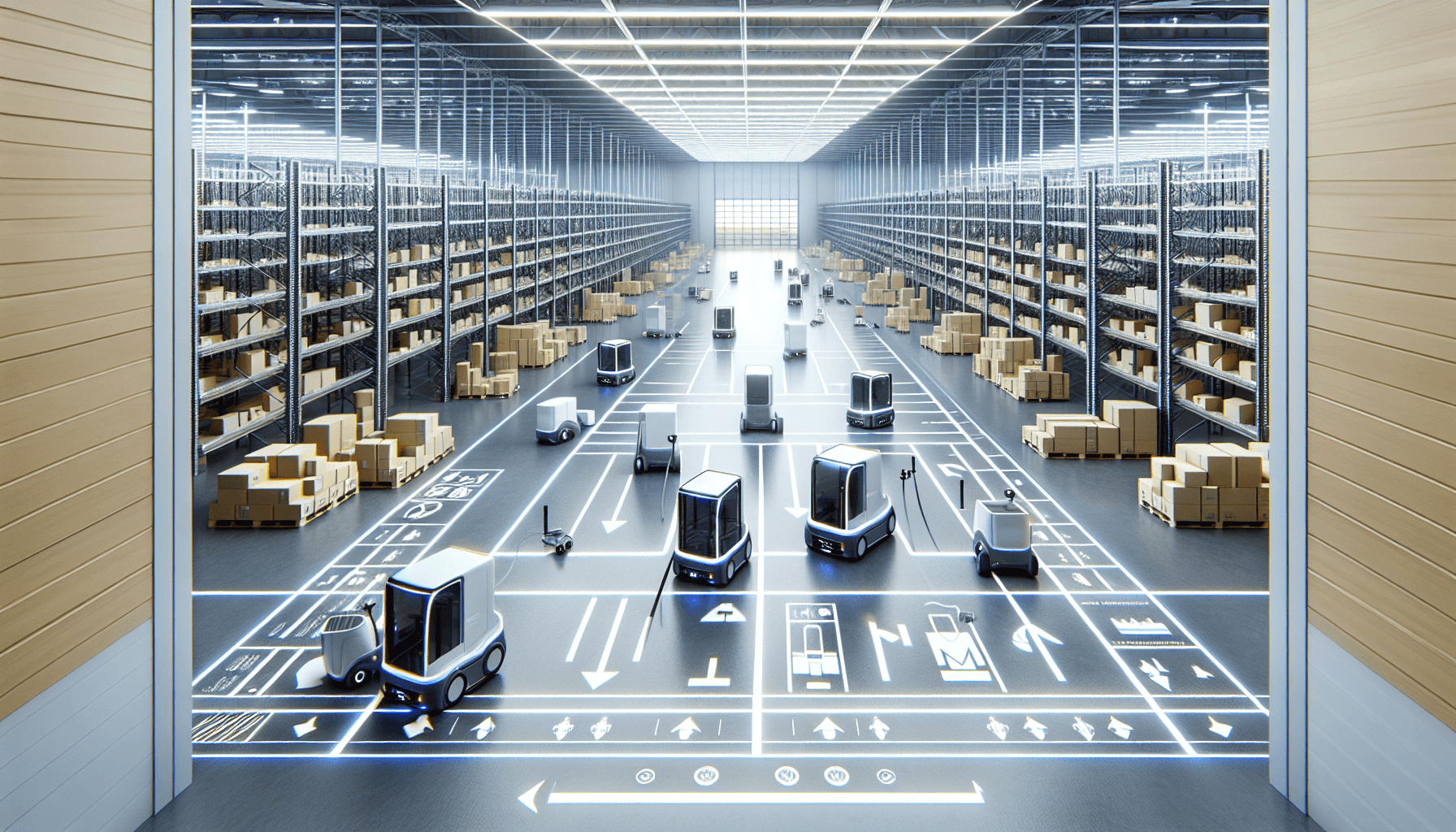

The warehouse layout plays a crucial role in facilitating efficient AGV operations. Key elements to consider when optimizing the layout include:

- Receiving and Shipping Areas: Designate separate areas for receiving and shipping, ensuring sufficient space for AGVs to maneuver and load/unload goods.

- Storage Systems: Utilize efficient storage systems such as racks, shelves, or automated storage and retrieval systems (AS/RS) to maximize storage capacity and accessibility for AGVs.

- Workstations and Pick Zones: Strategically position workstations and pick zones to minimize AGV travel time and optimize order picking processes.

- Pathways and Traffic Flow: Create clear pathways and define traffic flow patterns to prevent congestion and enable smooth movement of AGVs.

By optimizing the warehouse layout, you can minimize travel distances for AGVs, improve picking efficiency, and enhance overall productivity.

3. Implement AGV-Friendly Infrastructure

To ensure efficient AGV operations, the warehouse infrastructure needs to be AGV-friendly. Some key factors to consider when designing the infrastructure include:

- Flooring: Ensure the flooring is even, durable, and suitable for AGV navigation. Implementing floor markings or magnetic guidance systems can help guide AGVs along designated paths.

- Power and Charging: Install charging stations strategically throughout the warehouse to support AGV battery charging and maintenance.

- Lighting: Adequate lighting is essential for AGVs to navigate and detect obstacles. Install appropriate lighting fixtures to ensure optimal visibility within the warehouse.

- Communication Systems: Implement wireless communication systems to facilitate real-time communication between AGVs and the warehouse management system (WMS).

By incorporating AGV-friendly infrastructure, you can enhance safety, minimize downtime due to maintenance, and streamline AGV operations.

4. Integrate Warehouse Management System (WMS)

A robust Warehouse Management System (WMS) is essential for the seamless coordination of AGV operations. A WMS helps optimize inventory control, order fulfillment, and AGV task assignments. It provides real-time visibility into inventory levels, order status, and AGV locations, allowing for efficient inventory management and dynamic routing of AGVs.

Integrating a WMS with AGVs enables functionalities such as inventory tracking, automated replenishments, and intelligent order allocation, resulting in improved operational efficiency and accuracy.

5. Focus on Safety

Ensuring safety is paramount when designing a warehouse for AGV operations. Here are some safety considerations to keep in mind:

- Barriers and Guardrails: Install barriers and guardrails to separate AGV pathways from pedestrian walkways and prevent accidental collisions.

- Safety Sensors: Implement safety sensors on AGVs to detect obstacles and stop or reroute when necessary.

- Emergency Stop Buttons: Place emergency stop buttons strategically throughout the warehouse, allowing employees to halt AGVs if needed.

- Employee Training: Provide comprehensive training to warehouse staff on AGV operations, safety protocols, and emergency procedures.

By prioritizing safety measures, you can minimize the risk of accidents and create a secure working environment for both AGVs and warehouse personnel.

Designing a warehouse for AGV operations requires careful planning, analysis, and implementation. By considering the specific requirements, optimizing the layout and infrastructure, integrating a WMS, and emphasizing safety, you can create a warehouse that maximizes the benefits of AGV technology.

If you want to learn more about warehouse optimization and AGV deployment, visit HCO Innovations, a prominent provider of warehouse optimization solutions based in Raleigh, NC. They specialize in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations.