Forklifts are an essential tool for warehouse operations, helping to streamline the movement and transportation of goods within a facility. They rely on batteries to power their operations, making efficient forklift battery management crucial for maximizing productivity and minimizing downtime. In this article, we will discuss some best practices for implementing forklift battery management strategies.

Regular Maintenance and Inspections

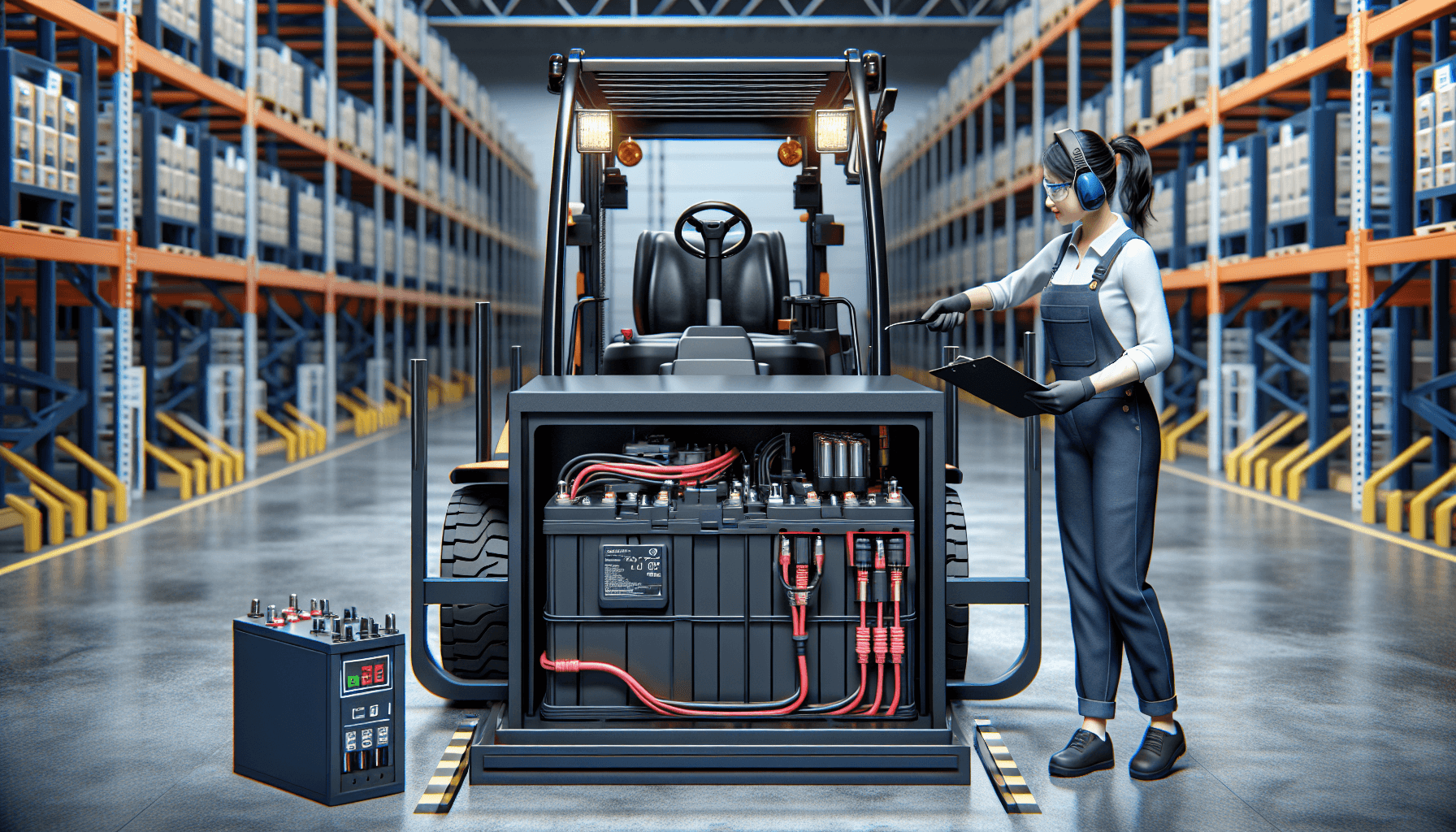

One of the key factors in ensuring optimal performance and longevity of forklift batteries is regular maintenance and inspections. Establishing a maintenance schedule and sticking to it is important in identifying and addressing any potential issues before they escalate. This includes checking for signs of wear, corrosion, or damage to the battery and its connections.

Additionally, conducting routine electrical tests and measurements can help identify any weaknesses or inefficiencies in the battery. This includes monitoring voltage levels, specific gravity, and water levels to ensure they fall within the recommended ranges. Regular maintenance and inspections are crucial for preventing unexpected battery failures and extending the lifespan of the battery.

Proper Charging and Discharging

Another important aspect of forklift battery management is implementing proper charging and discharging practices. Charging the batteries correctly not only ensures their longevity but also maximizes their performance and efficiency. It is essential to follow the manufacturer’s guidelines and recommendations for charging procedures and to use the correct charging equipment.

Overcharging or undercharging the batteries can have detrimental effects, leading to reduced battery life and decreased performance. It is important to properly monitor the charging process, avoid overcharging, and ensure that the charging cycles are completed. Implementing an automated battery management system can help monitor and control the charging process effectively.

Discharging the batteries correctly is equally important. Allowing the batteries to discharge too much before recharging can cause irreversible damage. Implementing a battery management system that monitors and controls the minimum voltage levels can help prevent over-discharge and extend the battery life.

Proper Battery Handling and Storage

Proper handling and storage of forklift batteries is crucial for the safety of employees and the longevity of the batteries themselves. When handling batteries, it is important to wear appropriate personal protective equipment (PPE) such as gloves and goggles to prevent any exposure to chemicals or acid leaks.

During storage, batteries should be kept in a clean, dry, and well-ventilated area. They should be stored in designated battery racks or on pallets, ensuring they are not in direct contact with the floor. Regularly inspecting the storage area for any signs of leaks or potential hazards is essential for maintaining a safe working environment.

Implementing a comprehensive forklift fleet power management solution can provide numerous benefits, such as optimizing charging processes, monitoring battery health, and efficient battery usage. These solutions use advanced technologies to improve the performance and longevity of forklift batteries, ultimately enhancing productivity and reducing costs.

Employee Training and Education

Lastly, providing proper training and education to forklift operators and maintenance personnel is essential for effective battery management. Employees should be trained on proper battery handling techniques, charging procedures, and recognizing signs of battery deterioration or malfunction.

Regularly conducting refresher training sessions and keeping employees up to date with the latest industry trends can help ensure consistent adherence to best practices. In addition, creating a culture of awareness and responsibility around forklift battery management can greatly contribute to the success of the overall strategy.

Implementing these forklift battery best practices can significantly enhance the safety, productivity, and efficiency of warehouse operations. By prioritizing regular maintenance, proper charging and discharging, adequate handling and storage, and ongoing training, businesses can maximize the performance and lifespan of their forklift batteries, ultimately leading to improved operational and cost-effectiveness.

Remember, HCO Innovations is your trusted partner in warehouse optimization solutions. Check out our website for more information on how we can help enhance your warehouse operations.