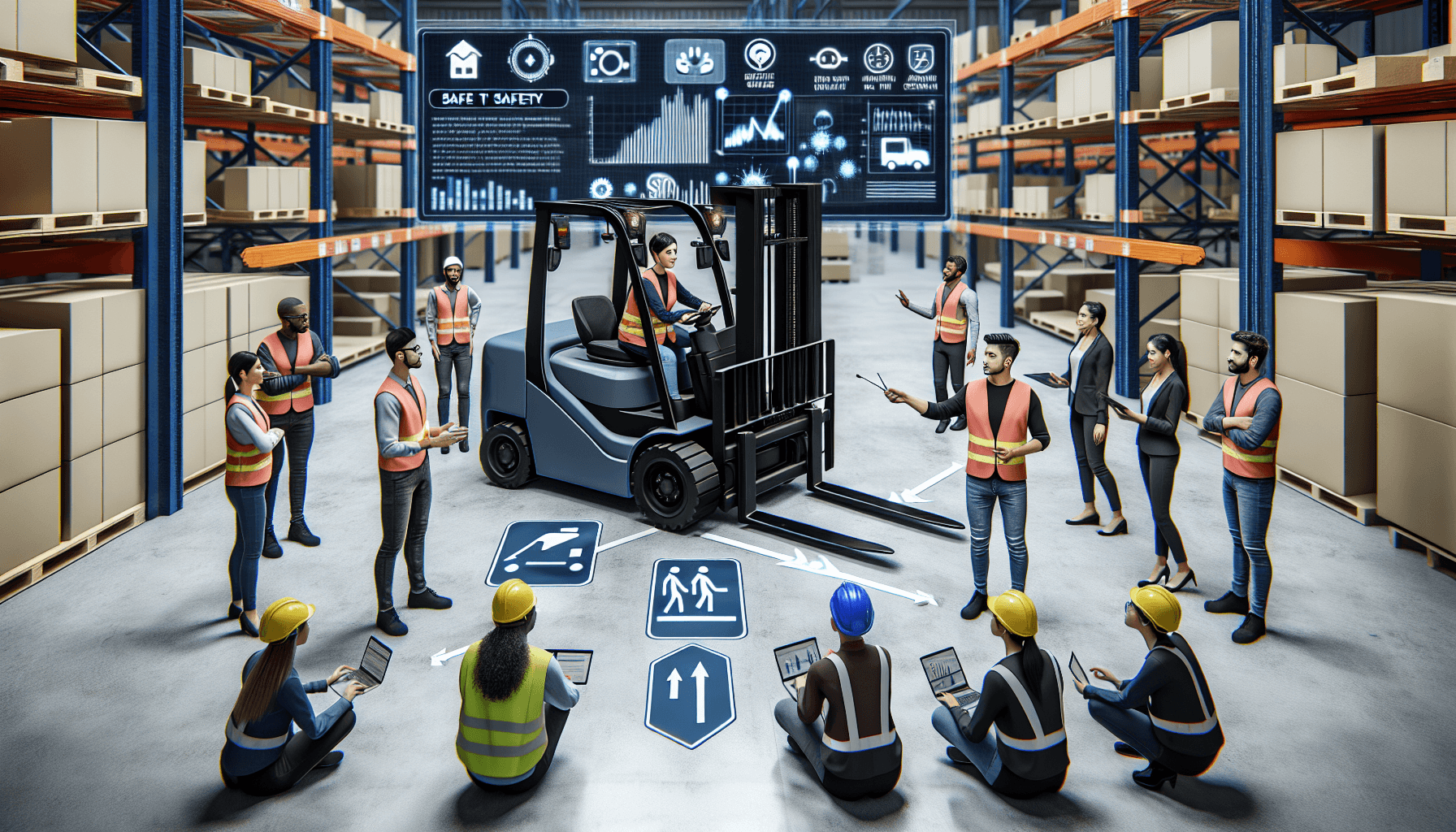

Implementing forklift safety measures in agile work environments is crucial to ensure the well-being of workers and the efficient operation of warehouse tasks. Forklifts are powerful machines used to lift and transport heavy loads, but they can also pose significant risks if not used properly. In this article, we will explore the essential steps you can take to implement forklift safety in agile work environments.

1. Provide Proper Training

The first and most critical step in implementing forklift safety is to provide comprehensive training for all operators. Forklift operators should receive training on safe operation, load handling, maneuvering, and parking. They should also be familiar with the warehouse layout, including any potential hazards such as ramps, narrow aisles, or blind spots.

It is recommended to hire a professional forklift training company to conduct the training sessions. They can provide hands-on demonstrations and practical exercises to ensure that operators are well-prepared to handle the forklifts safely. Regular refresher courses should also be conducted to reinforce the importance of safety protocols.

2. Establish Clear Traffic Management Procedures

In an agile work environment, where multiple tasks are happening simultaneously, it is essential to establish clear traffic management procedures to avoid collisions and accidents. This includes setting designated forklift lanes, pedestrian walkways, and enforcing speed limits.

Signage and markings should be used to clearly indicate these designated areas and promote awareness among workers. It is also crucial to educate all employees about the traffic management procedures and the importance of following them consistently.

3. Regularly Maintain and Inspect Forklifts

Maintaining and inspecting forklifts regularly is vital to ensure their safe operation. A scheduled maintenance program should be in place to address any potential issues or malfunctions promptly.

Operators should perform pre-shift inspections to check for any visible damage, fluid leaks, worn-out tires, or malfunctioning controls. Any identified issues should be reported and addressed immediately by a qualified technician before using the forklift.

4. Provide Personal Protective Equipment (PPE)

Personal protective equipment (PPE) plays a crucial role in forklift safety. All forklift operators and warehouse workers should be provided with the necessary PPE, including high-visibility vests, safety helmets, and steel-toe boots.

Properly fitting PPE should be worn at all times while operating or working around forklifts. Regular checks should be conducted to ensure compliance with PPE requirements and to replace any damaged or worn-out equipment.

5. Implement Safety Audits

Regular safety audits are crucial to identify any potential safety hazards and make necessary improvements. Safety audits should be conducted by trained professionals who can assess the overall safety performance of the warehouse, including forklift operations.

HCO Innovations offers a comprehensive warehouse safety evaluation service that can help identify safety gaps, provide recommendations, and assist in implementing best practices. Conducting safety audits periodically will ensure ongoing compliance with safety standards and continuous improvement in forklift safety.

Conclusion

Implementing forklift safety in agile work environments is crucial for the well-being of workers and the smooth operation of warehouse tasks. By providing proper training, establishing clear traffic management procedures, regularly maintaining and inspecting forklifts, providing personal protective equipment, and implementing safety audits, you can create a safe and productive work environment.

Remember, forklift safety is a shared responsibility, and everyone in the warehouse should be educated and aware of the protocols to ensure a safe working environment.