Improving forklift safety is crucial for warehouse operations to ensure enhanced performance and productivity. Forklifts are integral to the smooth functioning of warehouses, facilitating the movement of heavy materials and goods. However, poor forklift safety practices can lead to accidents, injuries, and damage to products and property. To avoid such incidents, it is essential for businesses to prioritize and implement effective forklift safety measures.

Training and Certification

A well-trained and certified forklift operator is key to maintaining a safe working environment. Companies should invest in comprehensive training programs that cover all aspects of operating a forklift, including proper handling techniques, load capacity understanding, and awareness of safety procedures. By providing regular training and certification programs, businesses can ensure that their forklift operators possess the necessary skills and knowledge to operate the machinery safely.

It is also important to conduct refresher training courses to reinforce safety practices and educate operators about new technologies and regulations. Continuous learning and updating knowledge is vital, as it helps operators stay informed about the latest safety standards and best practices.

Regular Equipment Maintenance

Well-maintained forklifts are less likely to malfunction and cause accidents. Implementing a regular maintenance schedule for all forklifts within a warehouse is essential. Routine inspections should be carried out to check for any signs of wear and tear, damaged parts, or potential issues that may affect the safe functioning of the machinery.

Additionally, it is necessary to follow the manufacturer’s guidelines for maintenance and servicing. This includes regular oil and fluid checks, battery examination, tire inspections, and proper lubrication. By adhering to a strict maintenance regimen, businesses can ensure that their forklifts are operating at optimal levels, reducing the risk of accidents caused by mechanical failures.

Implementing Safety Measures

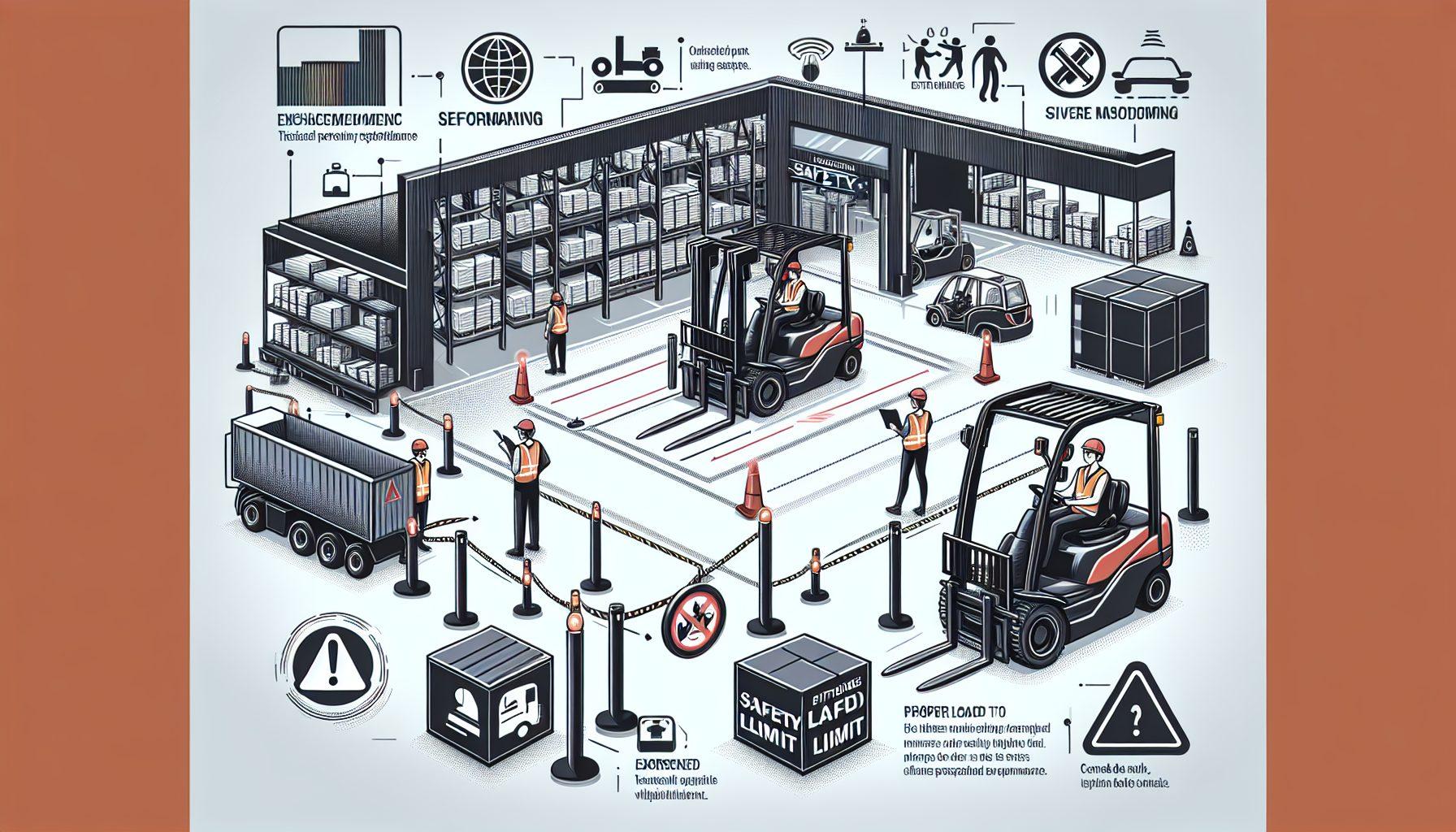

In addition to training and maintenance, warehouses should also implement specific safety measures to enhance forklift operations. Some key safety measures include:

- Clearly marked pedestrian walkways and forklift lanes to separate foot traffic and machinery movements.

- Installing mirrors and warning signs at blind spots and intersections to improve visibility.

- Ensuring proper lighting in the warehouse to facilitate clear visibility.

- Implementing speed limits for forklifts and enforcing strict adherence.

- Using seat belts and other safety devices to protect operators in case of accidents.

- Regularly monitoring and inspecting the warehouse layout to identify potential hazards and make necessary improvements.

By implementing these safety measures, businesses can significantly reduce the risk of accidents and create a safer working environment for forklift operators and other warehouse personnel.

Encouraging a Culture of Safety

Creating a culture of safety is crucial to maintain forklift safety within the warehouse. Businesses should actively encourage and engage employees in participating in safety programs and initiatives. This can be achieved by:

- Conducting regular safety meetings to discuss best practices, address concerns, and provide updates.

- Offering incentives or rewards for employees who adhere to safety guidelines and report potential hazards.

- Promoting open communication where employees feel comfortable speaking up about safety concerns.

- Leading by example, with management and supervisors demonstrating a commitment to safety protocols.

By fostering a culture of safety, businesses can create a proactive environment where employees prioritize safe practices and actively contribute to the overall well-being of the warehouse.

It is vital for businesses to constantly evaluate and improve forklift safety measures. Conducting regular warehouse safety evaluations, like the one offered by HCO Innovations, can help identify potential areas for improvement and address any safety gaps. A professional evaluation provides businesses with valuable insights and recommendations to enhance forklift safety, ensuring a safer and more productive warehouse environment. To learn more about HCO Innovations’ warehouse safety evaluation services, visit their website.

In conclusion, prioritizing forklift safety is crucial for enhancing performance and productivity in warehouse operations. By investing in training and certification programs, conducting regular equipment maintenance, implementing safety measures, and fostering a culture of safety, businesses can create a safe working environment for their forklift operators and other warehouse personnel. Remember, safety is everyone’s responsibility!