When it comes to warehouse operations, safety should always be a top priority. This is especially true in remote locations where additional challenges may arise. Remote warehouses are often characterized by their distance from support services and potential isolation, which can make addressing safety concerns more challenging.

The Importance of Forklift Safety

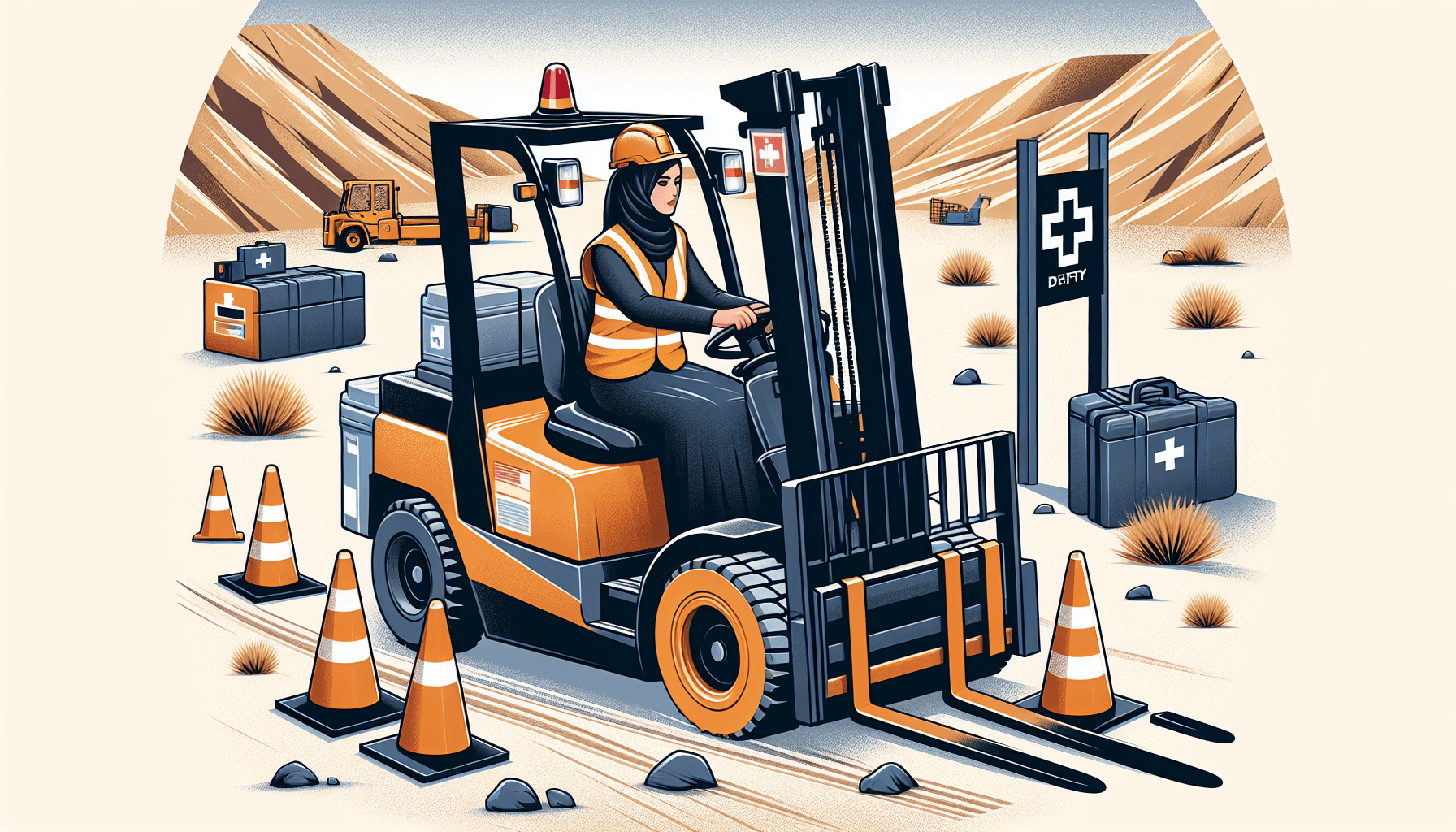

Forklifts are one of the most commonly used pieces of equipment in warehouses. They play a crucial role in materials handling and contribute significantly to productivity and efficiency. However, without proper safety measures in place, forklifts can also pose a significant risk to both operators and other employees in the warehouse.

According to the Occupational Safety and Health Administration (OSHA), forklift-related accidents account for a significant number of injuries and fatalities in workplaces each year. These accidents can result in serious injuries, such as fractures, crush injuries, or even death. It is essential for companies operating in remote locations to take proactive steps to improve forklift safety and reduce the risk of accidents.

Tips to Improve Forklift Safety in Remote Locations

1. Provide Comprehensive Training: Proper training is the cornerstone of forklift safety. Ensure that all forklift operators in remote locations receive comprehensive training that covers both theoretical knowledge and practical skills. Training should include safe operating procedures, load handling techniques, emergency protocols, and the safe operation of attachments.

2. Conduct Regular Maintenance: Regular maintenance and inspections are crucial to ensure forklifts are in good working condition. Develop a maintenance schedule and adhere to it strictly. This includes checking brakes, tires, lights, and other critical components. It is also important to address any maintenance issues promptly to avoid potential accidents.

3. Implement Clear Signage: In remote warehouses, it is important to have clear and visible signage to guide forklift operators and other employees. Signage should indicate speed limits, pedestrian walkways, and hazardous areas. Utilize bright colors and large fonts to enhance visibility, especially in low-light areas.

4. Utilize Technology: Implementing advanced technologies can greatly enhance forklift safety in remote locations. For example, using forklift monitoring systems that include features like real-time tracking, speed control, and collision detection can help prevent accidents. These systems can also provide valuable data for analyzing and improving safety practices.

5. Provide Personal Protective Equipment (PPE): Ensure that all employees, including forklift operators, have access to appropriate personal protective equipment. This may include high-visibility vests, safety helmets, protective footwear, and gloves. Regularly assess the condition of PPE and replace any damaged or worn-out items promptly.

6. Implement Traffic Management Plan: Develop a traffic management plan to minimize the risk of collisions and near-misses in remote locations. Clearly define traffic flow direction, create designated loading and unloading zones, and separate pedestrian walkways from vehicle traffic. Regularly review and update the plan as needed.

7. Encourage Reporting and Communication: Promote a culture of reporting and open communication regarding safety concerns in the workplace. Encourage employees to report any hazardous conditions or near-miss incidents involving forklifts. Conduct regular safety meetings to discuss issues, share best practices, and address any potential safety gaps.

8. Regularly Evaluate Safety Measures: Regularly evaluate the effectiveness of your forklift safety measures in remote locations. Seek feedback from forklift operators and other employees to identify potential areas for improvement. Consider conducting a comprehensive warehouse safety evaluation conducted by professionals like HCO Innovations to get an objective assessment of your safety practices. It can provide valuable insights and recommendations for enhancing safety in your remote warehouse operations.

While these tips can significantly improve forklift safety in remote locations, it is crucial to continually emphasize and prioritize safety in all warehouse operations. Regular training, ongoing maintenance, and fostering a safety-conscious culture are key elements to ensure a safe working environment for everyone.

Remember, safety should never be compromised, regardless of your warehouse’s location. By implementing these best practices and seeking expert guidance, you can minimize the risk of forklift accidents and create a safer working environment for your employees in remote locations.

Conclusion

Improving forklift safety in remote locations requires a proactive and comprehensive approach. By providing thorough training, focusing on maintenance and inspections, utilizing technology, implementing clear signage, and encouraging open communication, you can greatly reduce the risk of forklift accidents. Regularly evaluating your safety measures and seeking professional guidance can also help identify areas for improvement. Remember, a safe warehouse is a productive warehouse.

If you’re looking for expert assistance in evaluating your warehouse safety practices, HCO Innovations offers a comprehensive warehouse safety evaluation. This evaluation can provide valuable insights and recommendations for enhancing safety in remote locations and optimizing your warehouse operations.