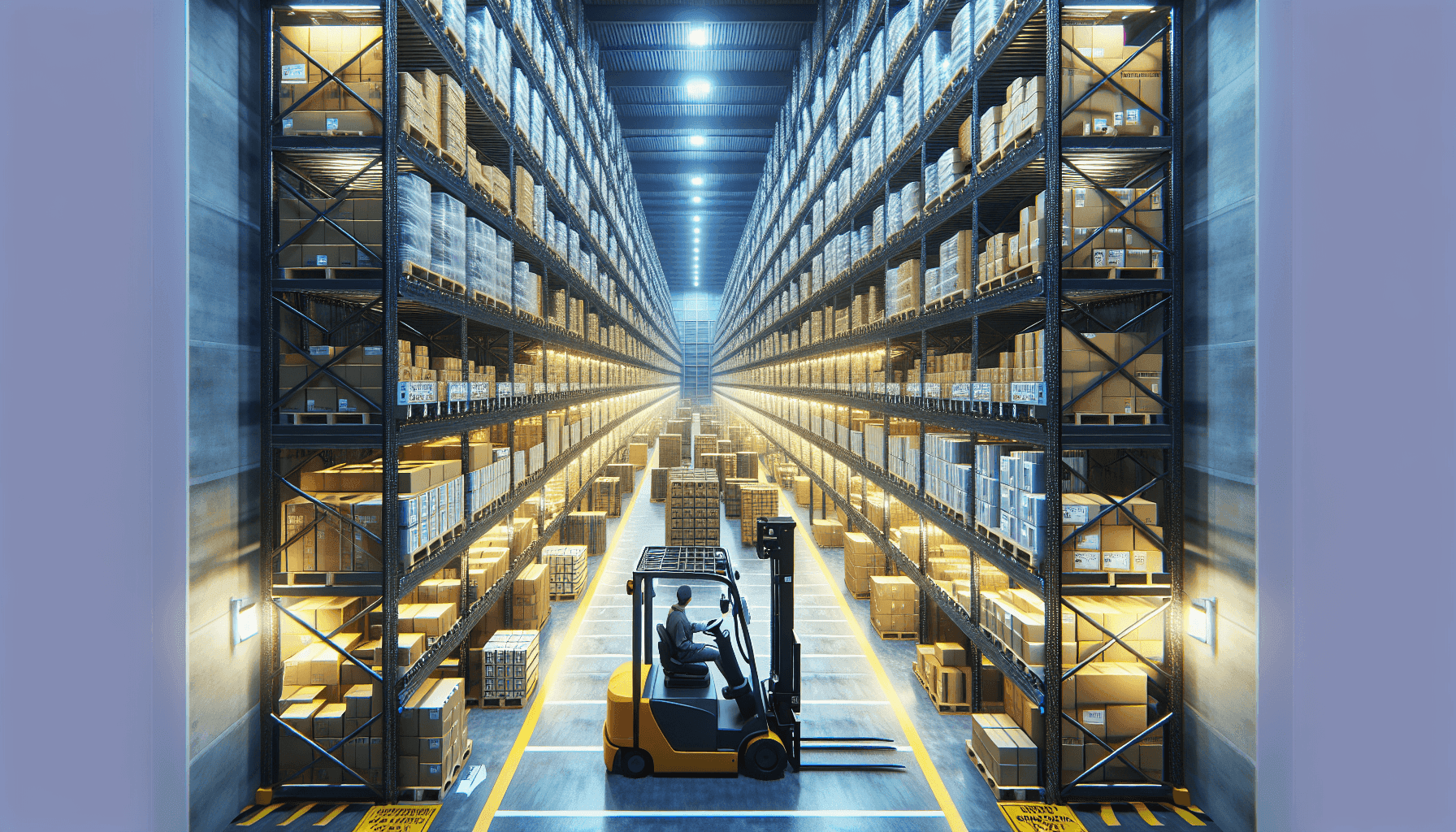

When it comes to running a warehouse efficiently, optimizing the layout is a crucial factor. A well-designed warehouse layout can significantly improve order picking efficiency, reduce errors, and enhance overall productivity. In this article, we will explore some key strategies to help you improve order picking efficiency with a better warehouse layout.

1. Analyze Your Current Warehouse Layout

The first step in improving order picking efficiency is to analyze your current warehouse layout. Take the time to thoroughly evaluate the existing layout and identify any bottlenecks, congested areas, or inefficient processes. This assessment will provide valuable insights into areas that need improvement.

Consider the flow of materials within your warehouse. Are there long travel distances between picking areas and shipping stations? Are aisles wide enough for forklifts or other equipment to navigate comfortably? Are high-demand items located close to the shipping area for faster access? Look for any potential areas where order picking efficiency can be enhanced.

2. Optimize Aisle Widths

Aisle width plays a crucial role in determining how efficiently your order pickers can navigate through the warehouse. Narrow aisles can save space but may slow down order picking operations, especially if you have larger equipment or pallet racks. On the other hand, wider aisles may provide ease of movement but can reduce your overall storage capacity.

It’s essential to strike a balance between aisle width and storage capacity. Consider implementing narrow aisles where possible and use narrow aisle forklifts or automated guided vehicles (AGVs) to optimize space. This will allow for faster and more efficient order picking while maximizing your storage capabilities.

3. Implement Efficient Slotting Practices

Slotting refers to the process of assigning products to specific locations in the warehouse. Proper slotting can have a significant impact on order picking efficiency. Analyze your product data and order history to determine which items are high-demand and frequently picked.

Place high-demand items in easily accessible locations, such as near the shipping area or at the front of the warehouse. This reduces the time taken to retrieve these items, resulting in faster order fulfillment. Additionally, grouping similar items together can minimize travel time and reduce the risk of errors during picking.

Investing in warehouse management software (WMS) can further optimize slotting practices. WMS can analyze order patterns and suggest the most efficient slotting locations, taking into account factors such as order frequency and product characteristics.

4. Utilize Vertical Space

Maximizing the use of vertical space is a crucial aspect of warehouse optimization. When your floor space is limited, going vertical can help you increase your storage capacity without expanding your physical footprint. Implementing tall racks, mezzanines, and multi-level shelving units can create additional storage space.

Consider using vertical lift modules (VLMs) or automated storage and retrieval systems (AS/RS) that can efficiently store and retrieve items from the height of the warehouse. These systems can significantly reduce the time taken for order pickers to access items stored at higher levels, improving order picking efficiency.

5. Invest in Warehouse Automation

One of the most effective ways to improve order picking efficiency is through warehouse automation. Automation can streamline and speed up order fulfillment processes, reducing the reliance on manual labor. By implementing technologies such as conveyor systems, robotic pickers, and automated sorting systems, you can significantly improve order picking speed and accuracy.

Automated systems can also integrate with your warehouse management system, allowing for better inventory control and real-time tracking of order status. This reduces the chances of picking errors and enhances overall order fulfillment efficiency.

6. Continuous Improvement and Training

Improving order picking efficiency is an ongoing process. It’s crucial to continually evaluate your warehouse operations, gather feedback from your team, and make necessary adjustments. Implement a continuous improvement program that encourages employees to provide suggestions and ideas for enhancing efficiency.

Regular training and cross-training of warehouse staff are also essential. Proper training ensures that employees are familiar with picking strategies, equipment operation, and safety protocols. This can significantly reduce errors, optimize workflows, and improve overall efficiency.

Conclusion

Improving order picking efficiency starts with a well-designed warehouse layout. Analyzing your current layout, optimizing aisle widths, implementing efficient slotting practices, utilizing vertical space, investing in automation, and continuously improving through training and feedback are key steps to enhance efficiency and productivity.

To streamline your warehouse layout evaluation process and get professional assistance in optimizing your warehouse, consider partnering with HCO Innovations. Our warehouse optimization solutions can help enhance safety, increase productivity, improve efficiency, and ensure cost-effectiveness. Contact HCO Innovations today to schedule a warehouse layout evaluation.

Click here to schedule a warehouse layout evaluation with HCO Innovations.