Are you looking to optimize your AGV navigation systems? Look no further! At HCO Innovations, we specialize in providing comprehensive warehouse optimization solutions, and today, we will guide you through the process of optimizing your AGV navigation systems for maximum efficiency and productivity.

Understanding AGV Navigation Systems

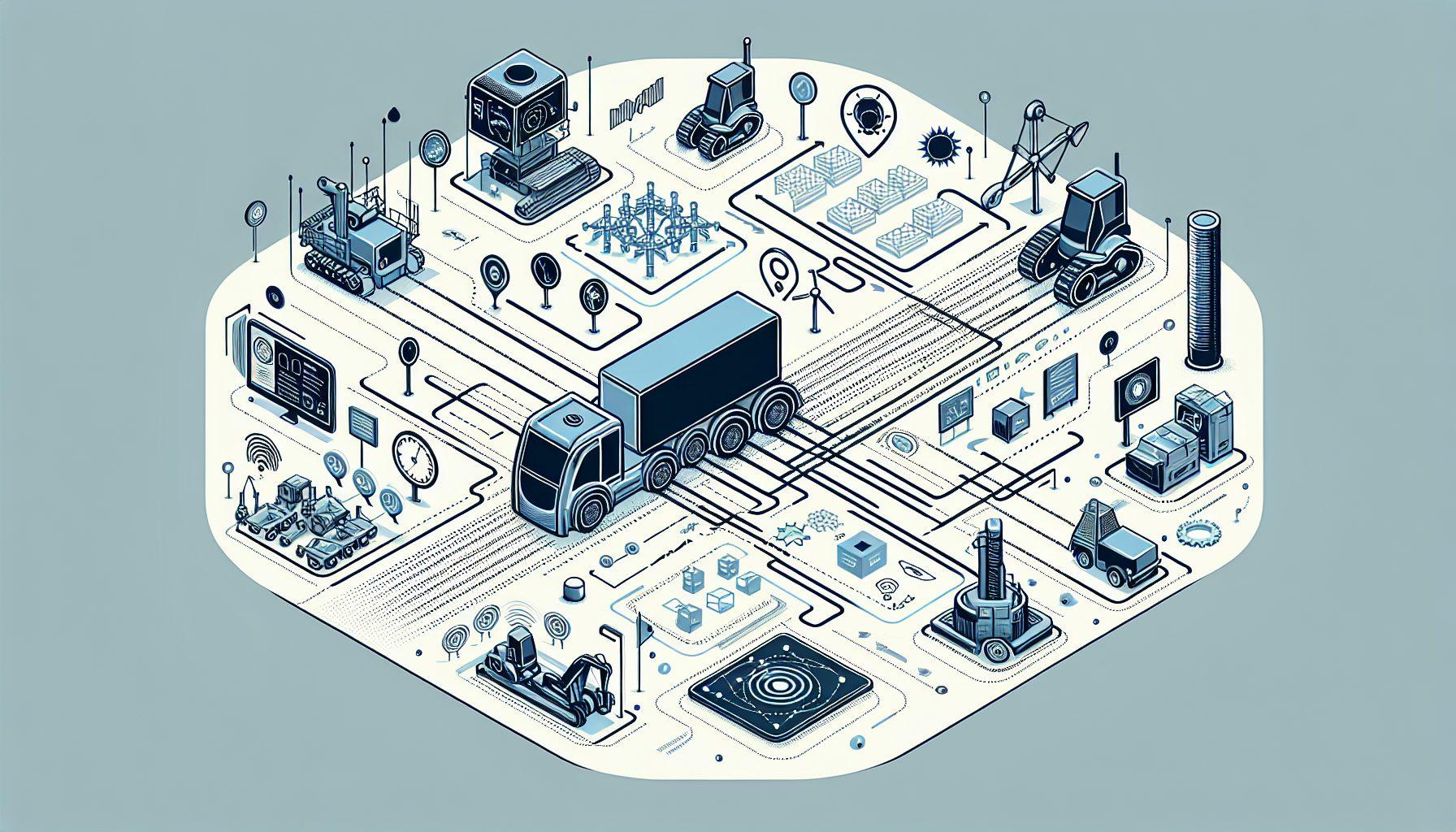

An AGV, or Automated Guided Vehicle, is a robotic material handling vehicle that operates within a warehouse or distribution center. AGVs are an essential part of modern warehouse operations, as they can perform repetitive tasks, such as picking, packing, and transporting goods, without the need for human intervention.

In order to perform their tasks efficiently and safely, AGVs rely on navigation systems. These navigation systems help AGVs determine their position within the warehouse and navigate through predefined paths and routes.

The Importance of Optimizing AGV Navigation Systems

Optimizing AGV navigation systems is crucial for enhancing overall warehouse productivity, efficiency, and safety. By fine-tuning these systems, you can minimize the risk of collisions, reduce unplanned stops, and improve the utilization of AGVs.

When AGV navigation systems are optimized, they can help streamline warehouse operations, shorten cycle times, and increase the accuracy of order fulfillment. This, in turn, leads to improved customer satisfaction and cost-effectiveness for your business.

Tips for Optimizing AGV Navigation Systems

Now that we understand the importance of optimizing AGV navigation systems, let’s dive into some practical tips to help you achieve optimal performance:

- Map your Warehouse: Start by thoroughly mapping your warehouse. This involves creating a detailed layout of the facility, including aisles, racks, and workstations. Mapping your warehouse will provide the necessary information for programming the AGV navigation system.

- Define Navigation Routes: Once the warehouse is mapped, it’s time to define the navigation routes for AGVs. Determine the most efficient paths for AGVs to travel between different areas of the warehouse, considering factors such as traffic flow, proximity to workstations, and avoiding obstacles.

- Implement Collision Avoidance: AGVs should be equipped with collision avoidance systems to prevent accidents and damages to goods or equipment. These systems use various sensors, such as cameras, ultrasonic sensors, or lasers, to detect obstacles and take evasive actions.

- Optimize Traffic Control: To minimize congestion and maximize the flow of AGVs, it’s essential to optimize traffic control. This can include implementing traffic management software that coordinates AGV movements, manages intersection priorities, and ensures smooth traffic flow.

- Continuous Monitoring and Updates: AGV navigation systems should be continuously monitored and updated to address any emerging issues or changes in the warehouse environment. Regular maintenance and software updates will ensure that your AGVs are operating at their best.

By following these tips, you can optimize your AGV navigation systems and unlock their full potential for your warehouse operations.

The HCO Innovations Advantage

When it comes to optimizing AGV navigation systems, partnering with HCO Innovations can give you a significant advantage. We have years of experience in warehouse optimization and can tailor solutions to meet your specific needs.

Our team of experts will work closely with you to analyze your warehouse layout, define navigation routes, and implement collision avoidance systems. We will also provide ongoing support to ensure your AGV navigation systems are always performing at their best.

Ready to optimize your AGV navigation systems? Contact HCO Innovations today and let us help you revolutionize your warehouse operations.