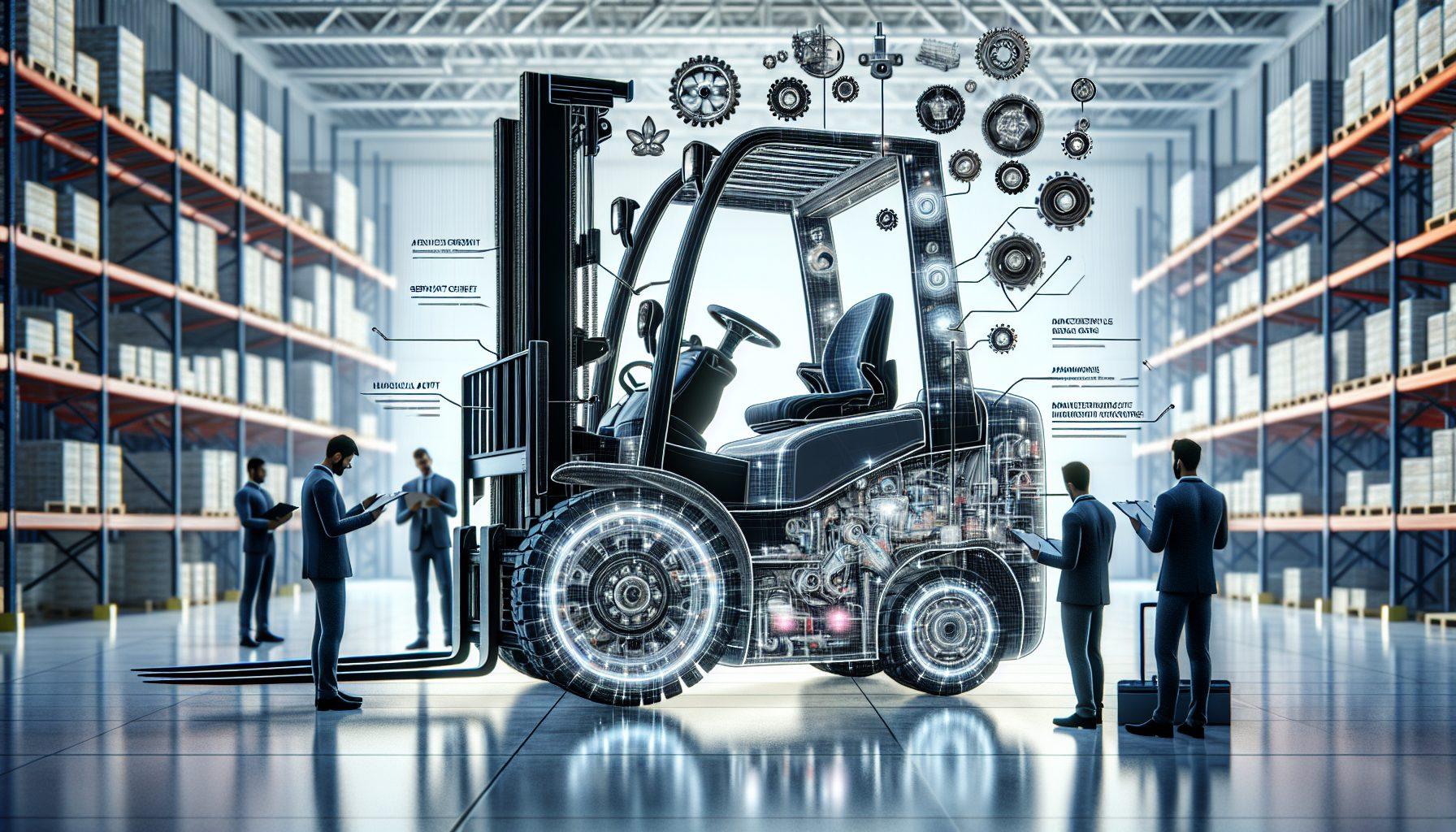

In the fast-paced world of warehouse operations, maintaining and optimizing the efficiency of forklifts is crucial. Forklifts play a vital role in moving and handling materials, which is why regular maintenance audits are imperative for the smooth running of warehouse operations. In this article, we will discuss the benefits of forklift maintenance audits and how they can contribute to enhancing safety, productivity, and cost-effectiveness within warehouse operations.

1. Improved Safety

Ensuring the safety of warehouse workers and the equipment they operate is of utmost importance. Forklift maintenance audits help identify any potential safety hazards and address them promptly. Regular checks and inspections can prevent accidents, breakdowns, and other mishaps that can occur when forklifts are not functioning optimally.

By conducting routine maintenance audits, warehouse managers can identify any issues with forklift components such as brakes, tires, lights, and other safety features. Timely repairs and replacements can be made, reducing the risk of accidents and injuries in the workplace. This not only protects the well-being of employees but also minimizes the potential for damage to products and property.

2. Increased Efficiency

Efficiency is a key factor in warehouse operations. Forklift maintenance audits play a crucial role in maximizing the efficiency of forklifts. Regular inspections and servicing help identify and address any performance issues or malfunctions that may be affecting productivity.

During maintenance audits, technicians can identify worn-out or faulty parts and replace them accordingly. This ensures that the forklifts are operating at their optimal capacity, allowing for faster and more efficient material handling. Well-maintained forklifts can also help reduce downtime caused by unexpected breakdowns, further improving overall operational efficiency.

Moreover, maintenance audits can also involve assessing operator performance and providing any necessary training or guidance. This helps operators utilize forklifts more efficiently, making the most out of their capabilities and minimizing time wastage.

3. Cost-Effectiveness

Investing in regular forklift maintenance audits can lead to significant cost savings in the long run. By addressing maintenance and performance issues early on, businesses can avoid costly repairs or complete replacements of forklifts.

Regular maintenance can help extend the lifespan of forklifts, reducing the need for premature replacements. It also helps enforce warranty requirements and ensures that the forklifts remain in compliance with manufacturer specifications. This can save businesses from potential penalties or claims due to equipment misuse or neglect.

Furthermore, well-maintained forklifts are more fuel-efficient, reducing operational costs. By keeping tires properly inflated, engines tuned, and oil changed regularly, forklifts can perform optimally, requiring less fuel for the same tasks.

HCO Innovations is a leading provider of turnkey forklift maintenance solutions that can help businesses optimize their warehouse operations. Their comprehensive maintenance audits cover all aspects of forklift performance and safety, ensuring the highest level of operational efficiency and cost-effectiveness.

Conclusion

Forklift maintenance audits are essential for warehouse operations seeking to enhance safety, productivity, and cost-effectiveness. By conducting regular inspections, businesses can identify and address any safety hazards or performance issues promptly. This helps create a safer work environment, improves operational efficiency, and reduces long-term costs. Partnering with a reliable provider like HCO Innovations can further streamline forklift maintenance and ensure optimal performance at all times.

What is a forklift maintenance audit?

A forklift maintenance audit is a comprehensive inspection and evaluation of a forklift's condition, performance, and compliance with safety standards. It involves checking various components, such as tires, brakes, hydraulics, and electrical systems, to ensure they are functioning properly and meeting required standards.

Why is forklift maintenance important?

Forklift maintenance is crucial for several reasons. First, it helps prevent breakdowns and costly repairs by identifying and addressing issues before they escalate. Regular maintenance also ensures optimal performance, efficiency, and longevity of the forklift. Additionally, proper maintenance helps fulfill safety requirements, reducing the risk of accidents and injuries in the workplace.

How often should forklift maintenance audits be conducted?

The frequency of forklift maintenance audits depends on various factors, such as the forklift's usage intensity and operating conditions. However, it is generally recommended to conduct these audits at least annually. Additionally, regular daily, weekly, and monthly inspections should be performed by operators as part of routine maintenance.

What are the benefits of conducting forklift maintenance audits?

There are several benefits to conducting forklift maintenance audits. Firstly, it helps identify potential safety hazards and allows for preventive measures to be taken to mitigate risks. Secondly, it helps minimize downtime and improves productivity by ensuring the forklift operates at peak efficiency. Thirdly, maintenance audits help extend the operational life of the forklift and reduce long-term costs associated with repairs and replacements.

Can I perform forklift maintenance audits myself, or should I hire professionals?

While operators should perform daily inspections and report any visible issues, it is highly recommended to hire qualified professionals for comprehensive maintenance audits. Certified technicians have the expertise to identify potential problems that may not be apparent to untrained individuals. Their thorough inspections and specialized knowledge ensure all aspects of the forklift are properly evaluated and serviced.

What should I look for in a forklift maintenance provider?

When selecting a forklift maintenance provider, consider their experience and reputation in the industry. Look for certifications and qualifications that indicate their expertise and adherence to industry standards. It is beneficial to choose a provider that offers tailored maintenance plans, responsive customer support, and a wide range of services, including emergency repairs.

The environmental impact of electric forklifts

The environmental impact of electric forklifts

Introduction

With the growing concern for environmental sustainability and reducing carbon emissions, industries are continually seeking ways to go green. One area that is often overlooked in this pursuit is material handling equipment, specifically forklifts. Forklifts are an essential part of warehouse operations, used for lifting heavy loads and transporting them within the facility. However, traditional forklifts powered by internal combustion engines contribute to air pollution and are not environmentally friendly.

At HCO Innovations, we specialize in warehouse optimization and forklift fleet management, and we understand the importance of sustainable practices. In this article, we will explore the environmental impact of electric forklifts and how they offer a greener alternative for businesses looking to reduce their carbon footprint.

The environmental benefits of electric forklifts

Electric forklifts are becoming increasingly popular due to their numerous environmental benefits. Let's take a closer look at how these vehicles help reduce carbon emissions and contribute to a greener future:

- Zero emissions: Unlike their internal combustion counterparts, electric forklifts produce zero emissions during operation. They are powered by rechargeable batteries, eliminating harmful pollutants such as carbon monoxide and nitrogen oxides. This not only improves air quality within the warehouse but also reduces the overall carbon footprint of the operation.

- Energy efficiency: Electric forklifts are highly energy-efficient compared to their gas or diesel-powered counterparts. They convert a higher percentage of electrical energy into mechanical energy, resulting in less energy waste. Additionally, regenerative braking systems used in electric forklifts help recapture and store energy that can be used for subsequent lifts, further improving efficiency.

- Noise reduction: Traditional forklifts powered by internal combustion engines can be incredibly noisy, contributing to noise pollution in the workplace. Electric forklifts, on the other hand, operate silently, creating a quieter and more conducive working environment for employees.

- Reduced maintenance: Electric forklifts have fewer moving parts compared to their combustion engine counterparts, resulting in reduced maintenance requirements. They do not require oil changes or tune-ups, leading to cost savings for the business and reducing the generation of hazardous waste.

- Longer lifespan: Electric forklifts typically have a longer lifespan compared to their internal combustion counterparts. With proper maintenance and battery management, electric forklifts can provide reliable operation for many years, reducing the need for frequent replacements and the associated environmental impact of manufacturing new vehicles.

Implementing electric forklifts in your warehouse

If you are considering transitioning to electric forklifts in your warehouse, it is essential to plan and prepare for the switch. Here are a few steps to consider:

- Evaluate your needs: Assess your warehouse operations and determine the number and type of forklifts required. Consider factors such as load capacity, reach, and maneuverability to ensure that the electric forklifts meet your specific requirements.

- Infrastructure requirements: Electric forklifts require charging stations, so it's crucial to assess your facility's electrical capacity and plan for the installation of charging stations strategically. This includes considering the location of the charging stations and accessibility for drivers.

- Training and education: Train your operators on how to use and maintain electric forklifts. Electric forklifts have different operational characteristics compared to combustion engine forklifts, so it's important to provide proper training to ensure safe and efficient operation.

- Battery management: Develop a battery management plan to ensure the longevity and optimal performance of your electric forklift fleet. This includes proper storage, charging, and maintenance of the batteries.

- Work closely with a trusted partner: Working with a reputable forklift fleet management company like HCO Innovations can help streamline the transition process. They can assess your warehouse layout, provide safety assessments, and offer turnkey maintenance solutions to ensure a seamless integration of electric forklifts into your operations.

By implementing electric forklifts in your warehouse, you can significantly reduce your carbon footprint while enjoying various operational and cost benefits.

Conclusion

As industries strive towards sustainability and reducing their environmental impact, electric forklifts present a valuable solution. These eco-friendly vehicles offer numerous benefits, including zero emissions, energy efficiency, noise reduction, reduced maintenance, and longer lifespan. By transitioning to electric forklifts, warehouses can reduce their carbon footprint while enhancing overall operational efficiency. If you're considering incorporating electric forklifts into your warehouse operations, HCO Innovations can provide the expertise and guidance you need. Contact us today to learn how we can help optimize and manage your forklift fleet.

HCO Innovations - Your partner in warehouse optimization and forklift fleet management.