A well-designed warehouse layout is crucial for the efficient and effective operation of any warehouse. It plays a significant role in optimizing safety, productivity, efficiency, and cost-effectiveness within warehouse operations. In this article, we will explore the benefits of implementing a lean warehouse layout design and how it can positively impact your business.

Maximizing Space Utilization

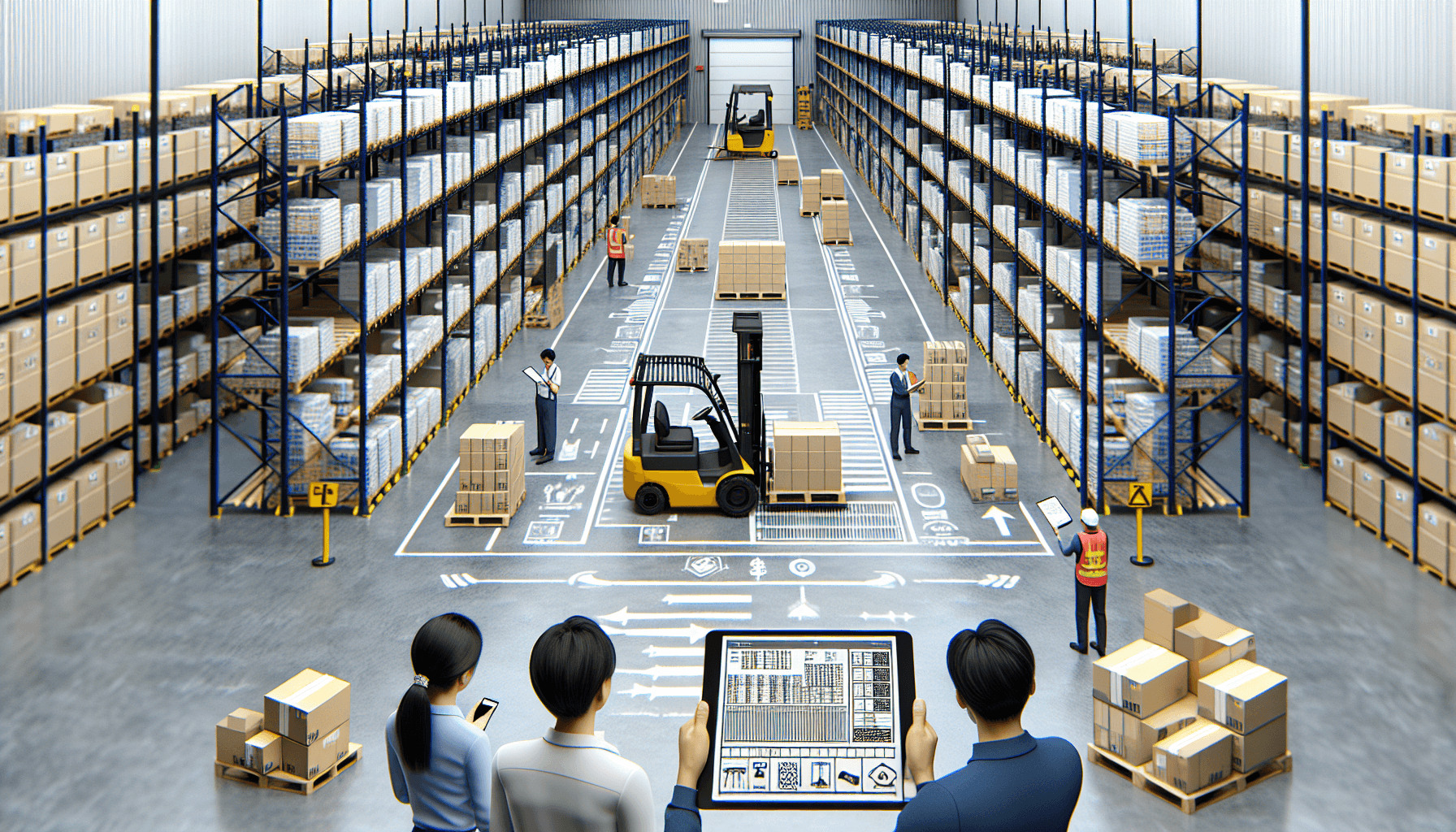

By implementing a lean warehouse layout design, you can make the most out of the available space in your warehouse. This is achieved by strategically organizing and arranging storage areas, workstations, and equipment to minimize wasted space. A well-designed layout ensures that every square footage of your warehouse is utilized effectively, enabling you to store more products and materials without the need for expansion.

One of the key elements of maximizing space utilization is the proper placement of storage racks and shelving units. By analyzing your inventory and the flow of goods, you can determine the most efficient location for each item. This reduces the need for excessive movement and minimizes the time spent searching for products, ultimately improving productivity and throughput.

Improved Workflow and Productivity

A lean warehouse layout design facilitates a smooth and streamlined workflow, leading to improved productivity. By placing storage areas, workstations, and equipment in a logical and efficient sequence, you can minimize travel distances and eliminate unnecessary movements. This reduces the time and effort required to complete tasks, enabling your team to work more efficiently.

Furthermore, a well-designed layout promotes organized and systematic workflows. Clear pathways, designated areas for specific tasks, and proper signage ensure that employees can easily locate and access the tools and resources they need. This reduces the potential for errors and delays, optimizing overall productivity levels.

Implementing lean principles, such as the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain), can further enhance productivity. By applying these principles to your warehouse layout, you can eliminate clutter, standardize work practices, and create an environment that fosters efficiency and continuous improvement.

Enhanced Safety

A well-designed warehouse layout is essential for ensuring the safety of your employees. By organizing storage areas, workstations, and traffic flow in a logical manner, you can minimize the risk of accidents, injuries, and collisions. Clear and unobstructed pathways reduce the chances of slips, trips, and falls, while proper signage and markings enhance visibility and awareness.

Additionally, a lean warehouse layout design takes into account the ergonomic considerations of employees. Workstations and equipment are positioned to minimize strain and fatigue, reducing the risk of musculoskeletal disorders. Adequate lighting, ventilation, and safety equipment are also incorporated into the design to create a safe and healthy working environment.

Optimized Inventory Management

In addition to improving operational efficiency, a lean warehouse layout design also leads to optimized inventory management. By organizing products in a logical and systematic manner, you can easily track and locate items, reducing the risk of stockouts and overstocks. This enables you to maintain optimal inventory levels, minimizing carrying costs and improving cash flow.

Furthermore, a well-designed layout allows for better visibility and accessibility of inventory. This makes it easier to conduct regular cycle counts and perform inventory audits, ensuring accurate inventory records and reducing discrepancies. By implementing lean inventory management practices, such as just-in-time (JIT) or kanban systems, you can further enhance efficiency and eliminate waste.

Are you looking to optimize your warehouse layout? HCO Innovations offers warehouse layout evaluation services to help you achieve a lean and efficient warehouse design. Our team of experts will assess your current layout, identify areas for improvement, and provide customized solutions to maximize space utilization, streamline workflows, and optimize inventory management. Contact us today at HCO Innovations to schedule your warehouse layout evaluation!