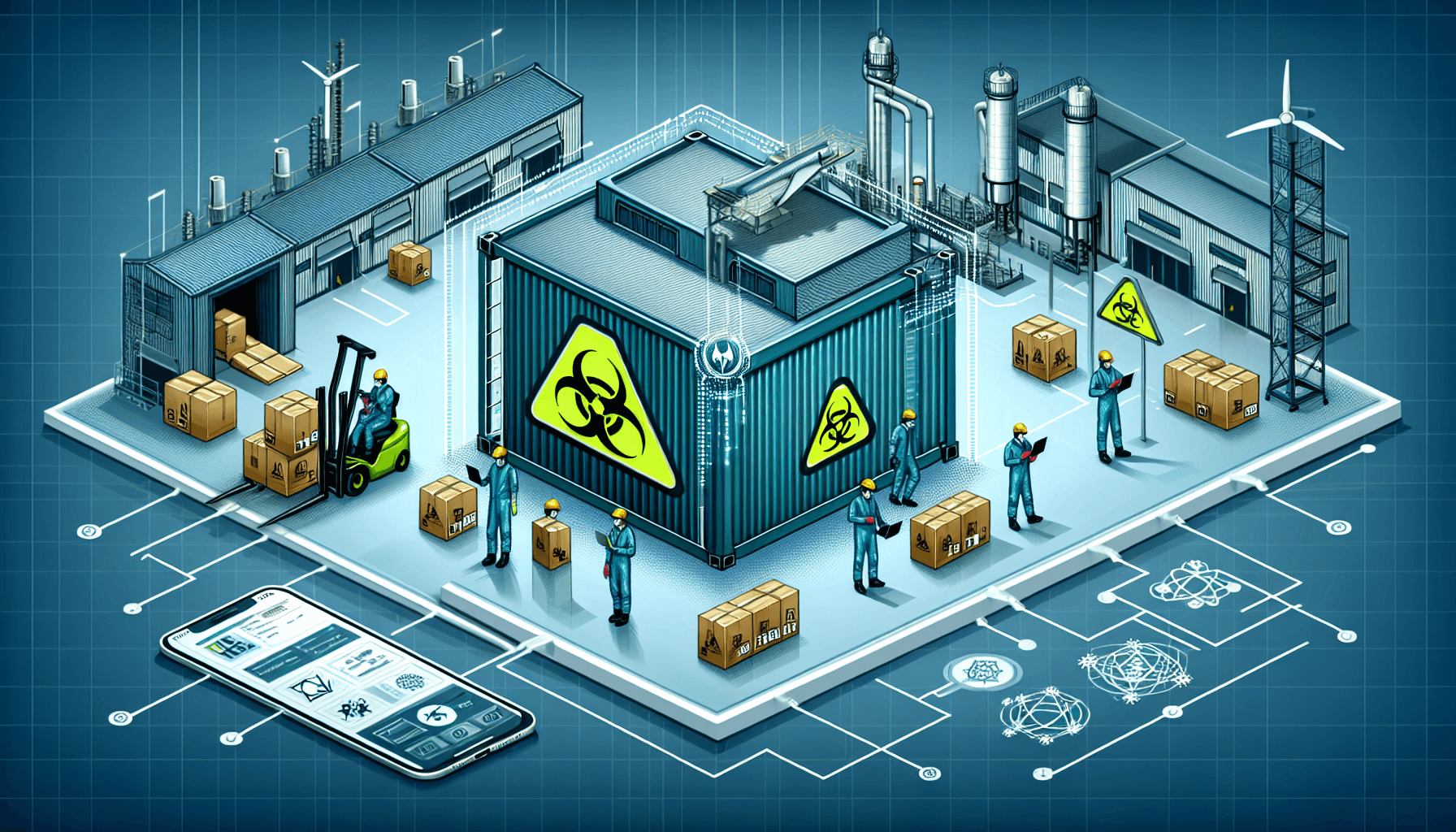

When it comes to handling hazardous materials within a warehouse, safety is of utmost importance. Ensuring the well-being of warehouse staff, protecting the environment, and complying with regulations are all critical aspects of managing hazardous materials effectively. That’s where Warehouse Management Systems (WMS) come into play.

The Importance of Hazardous Material Handling

Hazardous materials, also known as hazmat, can include various substances such as chemicals, flammable liquids, gases, or corrosive materials. These materials pose risks to people, property, and the environment if not handled properly. Warehouse operations dealing with hazardous materials need to follow strict protocols to prevent accidents, minimize the risk of exposure, and maintain compliance with regulatory standards.

From properly storing hazardous materials to ensuring their safe transportation and disposal, every step of the handling process is crucial. Warehouse managers and operators must have a comprehensive understanding of proper handling procedures to mitigate potential risks effectively.

The Role of Warehouse Management Systems in Hazardous Material Handling

A Warehouse Management System (WMS) is a technological solution that plays a vital role in optimizing warehouse operations across different industries. In the context of handling hazardous materials, WMS can add significant value by enhancing safety, productivity, and efficiency within the warehouse.

Here are some of the benefits of using a WMS for hazardous material handling:

1. Enhanced Safety

Safety is the top priority when dealing with hazardous materials. WMS provides warehouse staff with real-time visibility into the location, handling procedures, and storage requirements of hazardous materials. By streamlining processes and providing accurate information, a WMS helps reduce the risk of accidents, injuries, and exposure to hazardous substances.

Through the use of barcode or RFID labeling, WMS can ensure that hazardous materials are handled and stored correctly, minimizing the chances of mishaps due to human error. It can also track expiration dates, enforce proper storage guidelines, and provide alerts for any potential safety concerns.

2. Improved Compliance

Managing hazardous materials involves strict compliance with various regulations, including those set by government agencies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA). Non-compliance can lead to severe penalties, legal issues, and reputational damage for the warehouse.

A WMS can help warehouse operators adhere to these regulations by providing built-in compliance checks and automation. It can enforce proper storage and handling guidelines, ensure accurate documentation and reporting, and streamline the auditing process. By maintaining compliance with regulations, warehouses can avoid fines, penalties, and potential disruptions to their operations.

3. Efficient Inventory Management

Managing hazardous materials inventory requires careful monitoring and control. A WMS can significantly improve inventory management by providing real-time visibility into stock levels, locations, and movement of hazardous materials within the warehouse.

By utilizing features such as barcode scanning or RFID technology, a WMS enables accurate and efficient inventory tracking. It allows for easier identification of expired or soon-to-expire materials, preventing the use of outdated or potentially unsafe substances. Additionally, a WMS can optimize storage space, ensuring efficient use of the warehouse and minimizing the risk of incompatibilities or accidental mixing of hazardous materials.

4. Streamlined Processes and Increased Productivity

Manual processes can be time-consuming and prone to errors. With a WMS, warehouse operators can automate and streamline various aspects of hazardous material handling, resulting in increased productivity and efficiency.

Tasks such as order fulfillment, picking, packing, and shipping can be optimized through the use of a WMS. It can provide accurate instructions to warehouse staff, reducing the time spent searching for or handling hazardous materials. This not only improves overall productivity but also minimizes the risk of mistakes or accidents caused by human error.

Conclusion

Hazardous material handling requires careful attention to detail, adherence to safety protocols, and compliance with regulations. Incorporating a Warehouse Management System (WMS) into a hazardous material handling operation can bring numerous benefits.

From improving safety and ensuring compliance to optimizing inventory management and streamlining processes, a WMS is a valuable tool for warehouse managers and operators. With its ability to provide real-time visibility, automate tasks, and increase efficiency, a WMS from HCO Innovations can help warehouses effectively and safely handle hazardous materials, minimizing risks and maximizing productivity.