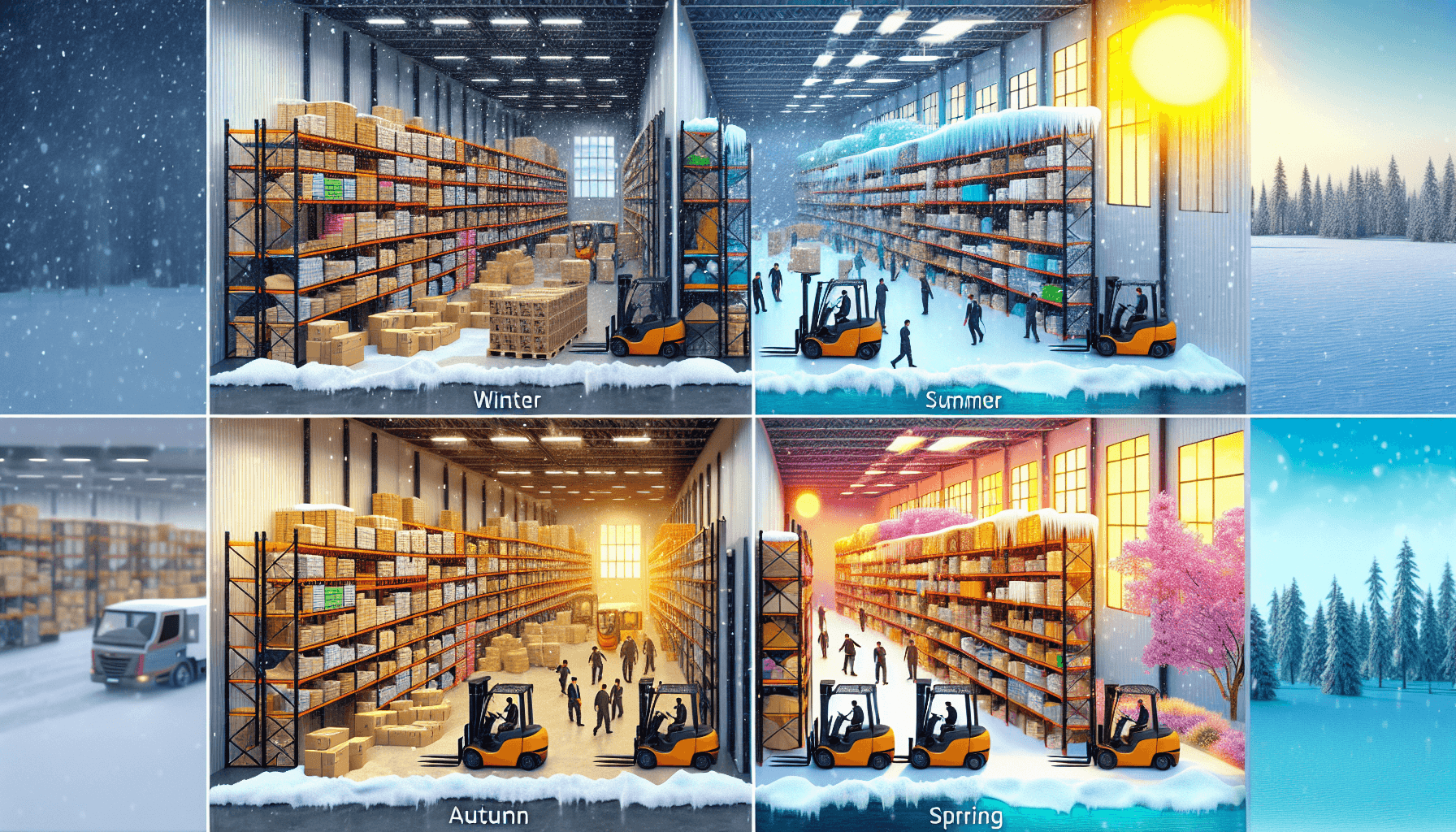

Seasonal fluctuations can have a significant impact on various aspects of business operations, and warehouses are no exception. As a prominent provider of warehouse optimization solutions, HCO Innovations understands the challenges that warehouse managers face when dealing with seasonal fluctuations. In this article, we will explore the impact of seasonal fluctuations on warehouse costs and how HCO Innovations can help warehouse operators mitigate these challenges.

Demand Variation and Inventory Management

One of the key factors affected by seasonal fluctuations is the demand for products. During peak seasons, such as holidays or special promotions, the demand for certain products may spike, requiring warehouse operators to stock up on inventory to fulfil customer orders. Conversely, during slower seasons, the demand may decrease, leading to excess inventory and unnecessary carrying costs.

Managing inventory effectively during seasonal fluctuations is crucial for warehouse cost optimization. HCO Innovations offers innovative solutions that utilize advanced data analytics and predictive algorithms to help warehouse managers forecast demand accurately. By implementing these solutions, warehouse operators can optimize their inventory levels, minimize carrying costs, and improve overall efficiency.

Workforce Planning and Labor Costs

Seasonal fluctuations can also impact workforce planning and labor costs in warehouses. During peak seasons, extra staff may be required to handle the increased workload, such as picking and packing orders, managing inventory, and fulfilling customer shipments in a timely manner. On the other hand, during slower seasons, warehouse operators may need to reduce their workforce to avoid unnecessary labor costs.

HCO Innovations offers workforce planning solutions that assist warehouse operators in efficiently managing their workforce during seasonal fluctuations. By analyzing historical data and considering factors like order volumes, HCO Innovations helps warehouse managers determine the optimal number of staff required during peak and off-peak seasons. This allows warehouse operators to keep labor costs in check without compromising on productivity or customer service.

Warehouse Layout and Storage Utilization

During seasonal fluctuations, warehouses often experience changes in the types and volumes of products they need to store. This can present challenges in terms of warehouse layout and storage utilization. Inefficient warehouse layouts can lead to wasted space, longer picking routes, and increased labor costs. Additionally, inadequate storage utilization may result in the need for additional warehouse space, adding to overall costs.

HCO Innovations specializes in warehouse optimization, assisting warehouse managers in finding the most efficient layout for their facilities. By using advanced technologies like virtual simulations and mathematical modeling, HCO Innovations designs optimized warehouse layouts that maximize storage capacity and minimize operational costs. Their expertise allows warehouse operators to adapt to seasonal fluctuations seamlessly while maintaining high levels of productivity and cost-effectiveness.

Transportation and Shipping Costs

Seasonal fluctuations can impact transportation and shipping costs for warehouses, especially when it comes to meeting customer delivery deadlines during peak seasons. Increasing shipping volumes, extra delivery routes, and the need for expedited shipping options can lead to higher transportation costs. Moreover, unreliable transportation logistics can result in delayed shipments and dissatisfied customers.

HCO Innovations offers comprehensive transportation optimization solutions that help warehouse operators streamline their shipping processes. By analyzing historical shipping data, optimizing delivery routes, and leveraging technology to track shipments in real-time, HCO Innovations enables warehouse operators to reduce transportation costs, improve delivery reliability, and enhance customer satisfaction, even during peak seasons.

Conclusion

Seasonal fluctuations can pose significant challenges for warehouses, affecting various aspects of operations, including demand variation, inventory management, workforce planning, warehouse layout, storage utilization, and transportation costs. However, HCO Innovations, with their expertise in warehouse optimization solutions, can help warehouse operators navigate these challenges and optimize costs during both peak and off-peak seasons.

To learn more about HCO Innovations’ warehouse cost analysis solutions and how they can assist your warehouse operations, visit https://www.hcoinnovations.com/warehouse-cost-analysis/.