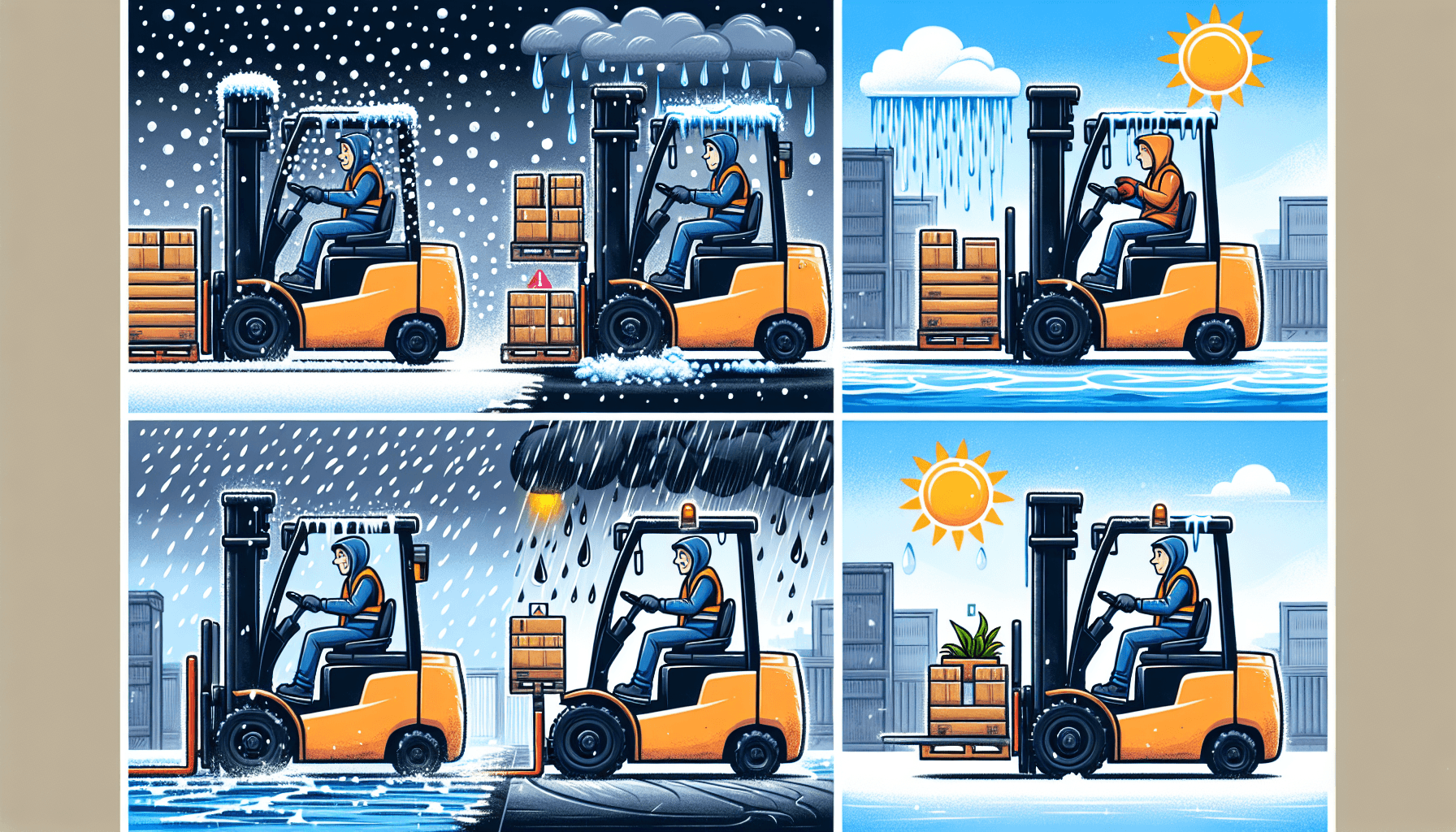

Weather conditions can have a significant impact on the safety of forklift operations in warehouses. Forklifts play a crucial role in warehouse operations, handling heavy loads and moving them efficiently. However, adverse weather conditions can pose additional challenges and risks to forklift operators and other warehouse personnel. In this article, we will explore the various ways in which weather conditions can affect forklift safety and discuss strategies for mitigating these risks.

1. Rain and Wet Surfaces

One of the most common weather conditions that can impact forklift safety is rain. When it rains, the warehouse floor surfaces can become wet and slippery, which increases the risk of forklifts skidding or losing traction. This can lead to accidents such as tip-overs or collisions with other equipment or warehouse structures.

To mitigate the risks associated with wet surfaces, it is essential to have proper drainage systems in place to prevent water accumulation on the warehouse floor. Implementing non-slip floor coatings or installing anti-skid mats in high-risk areas can also improve traction and reduce the likelihood of accidents.

Furthermore, forklift operators should receive training on safe operating practices in wet conditions, including maintaining a safe speed, increasing braking distance, and using appropriate caution when turning or reversing on slippery surfaces.

Regular warehouse safety evaluations can help identify areas that require additional precautions or improvements to ensure optimal safety in various weather conditions, including rain and wet surfaces.

2. Extreme Temperatures

Extreme temperatures, whether extreme heat or extreme cold, can also impact forklift safety. In excessively hot conditions, forklift operators may experience discomfort, fatigue, and dehydration, which can affect their concentration and decision-making abilities. On the other hand, extremely cold temperatures can cause materials and surfaces to become brittle, increasing the risk of accidents and equipment damage.

To address extreme temperatures, it is crucial to provide appropriate climate control in warehouse facilities. This can include installing insulation, ventilation systems, or air conditioning units to regulate the temperature and ensure a comfortable working environment for forklift operators. Implementing regular breaks and hydration protocols in hot conditions and providing suitable protective gear such as insulated gloves in cold conditions are also necessary measures to maintain forklift safety.

Training programs should also cover the effects of extreme temperatures on forklift operations and emphasize the importance of monitoring and responding to changes in temperature accordingly.

3. Strong Winds

Strong winds can pose a significant safety risk in outdoor warehouse areas or warehouses with open doors or windows. High winds can destabilize forklifts and cause them to tip over or deviate from their intended path. Additionally, flying debris or loose objects can be hazardous and cause injuries to both forklift operators and other personnel.

To minimize the impact of strong winds, it is important to maintain a clear and organized warehouse layout, ensuring that loose objects are properly secured or stored away. Regular inspections of outdoor areas should be conducted to identify any potential hazards such as loose signage, tree branches, or debris that can be moved by strong winds.

In extreme weather conditions, it may be necessary to limit or suspend forklift operations until the winds subside to ensure the safety of all personnel.

Conclusion

Weather conditions can significantly impact forklift safety in warehouse operations. Rain and wet surfaces increase the risk of skidding and collisions, extreme temperatures can affect operator performance, and strong winds can destabilize forklifts and cause accidents. By implementing appropriate safety measures, conducting regular evaluations, and providing comprehensive training to forklift operators, warehouse managers can mitigate the risks associated with adverse weather conditions and ensure a safer working environment for all personnel.

In need of a warehouse safety evaluation? Contact HCO Innovations, the leading provider of warehouse optimization solutions. Their expertise in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations can help you identify potential risks and implement effective solutions.