Warehouse compliance is of utmost importance for businesses operating in the logistics industry. With the increasing demand for speed, accuracy, and efficiency in warehouse operations, companies are constantly on the lookout for innovative solutions to improve compliance. One such technology that is revolutionizing warehouse operations is the use of Autonomous Guided Vehicles (AGVs).

The Role of AGVs in Enhancing Warehouse Compliance

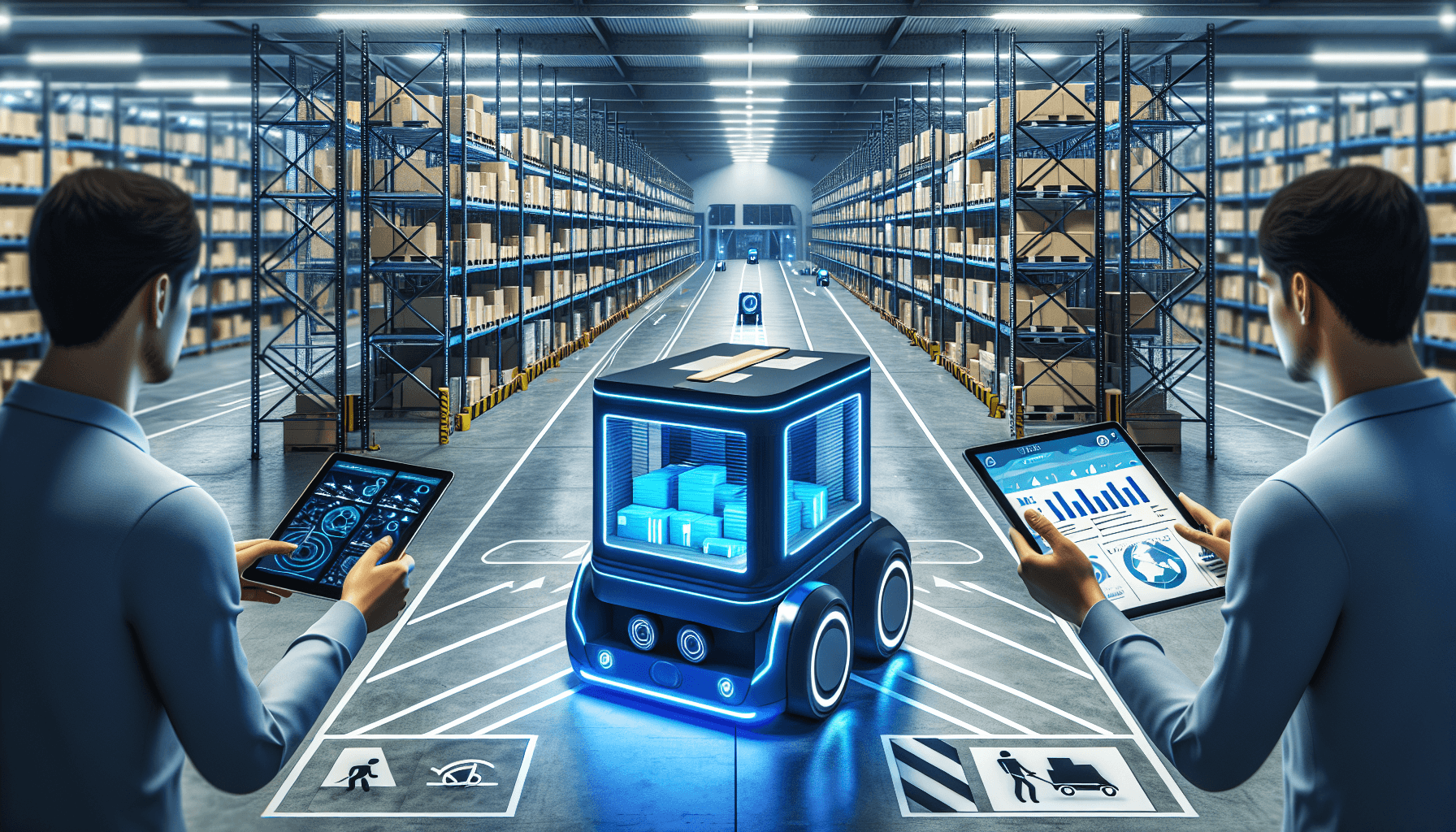

AGVs are self-driving vehicles that operate within warehouse environments to automate material handling tasks. These vehicles can navigate through the warehouse floor using a combination of sensors, cameras, and advanced software algorithms. AGVs have been widely adopted in warehouses to streamline operations, increase efficiency, and ensure compliance with various regulations and safety standards.

So, how do AGVs contribute to enhancing warehouse compliance? Let’s delve into some key areas:

1. Safety Compliance

Safety is a top priority in warehouse operations, and AGVs help ensure compliance with safety regulations. These autonomous vehicles are equipped with sophisticated safety features such as collision avoidance systems, sensor-based obstacle detection, and emergency stop mechanisms. By eliminating the need for manual material handling, AGVs reduce the risk of accidents and injuries, promoting a safer work environment.

AGVs can also be programmed to follow strict safety protocols, such as maintaining a safe distance from employees, pedestrians, and other warehouse equipment. They can navigate through narrow aisles and tight spaces with precision, minimizing the chances of collisions or damage to inventory.

2. Productivity Compliance

Warehouse productivity is crucial for meeting customer demands and maintaining a competitive edge. AGVs contribute to productivity compliance by streamlining material handling operations. These vehicles can efficiently transport goods, pallets, and containers within the warehouse, eliminating the need for manual labor and reducing processing times.

AGVs can also be integrated with warehouse management systems (WMS) and other automation technologies to optimize order fulfillment processes. By seamlessly communicating with other components of the warehouse infrastructure, AGVs ensure accurate inventory tracking, efficient picking, packing, and shipping operations.

Furthermore, AGVs operate continuously without breaks, fatigue, or human limitations, enabling round-the-clock productivity. This helps organizations meet demanding supply chain schedules and achieve higher throughput while complying with productivity targets.

3. Efficiency Compliance

Efficiency in warehouse operations is essential for minimizing costs and maximizing profitability. AGVs play a significant role in achieving efficiency compliance by optimizing material flow and space utilization within the warehouse.

AGVs are designed to make intelligent decisions while navigating the warehouse floor. They can analyze the best routes to follow, avoiding congested areas and utilizing the most efficient paths. By reducing travel distances and optimizing pick-up and drop-off locations, AGVs help minimize the time taken to complete tasks and increase overall operational efficiency.

In addition, AGVs can also assist with inventory management, ensuring accurate stock counts, and reducing the chances of stockouts or overstocks. By eliminating manual inventory checks and automating cycle counts, AGVs contribute to improved inventory accuracy and efficient replenishment processes.

4. Cost-effectiveness Compliance

AGVs offer cost-effective solutions for warehouse management. While the initial investment may seem significant, the long-term benefits outweigh the costs. AGVs eliminate the need for hiring and training manual labor for repetitive and physically demanding tasks, reducing labor costs and ensuring consistent performance.

Moreover, AGVs help optimize space utilization within the warehouse. Their compact design and ability to navigate through tight spaces allow for better utilization of storage areas. This can lead to reduced warehouse footprint requirements and lower rental or construction costs.

Furthermore, AGVs can contribute to a reduction in product damage and losses. With their advanced sensors and careful navigation, AGVs minimize the chances of collisions with inventory or equipment, resulting in fewer damaged goods.

In conclusion, AGVs play a vital role in enhancing warehouse compliance by ensuring safety, improving productivity, increasing efficiency, and achieving cost-effectiveness. If you’re interested in deploying AGVs in your warehouse operations, HCO Innovations can help. With their expertise in warehouse optimization solutions, HCO Innovations offers comprehensive AGV deployment services. Visit their website to learn more about their services and how they can help transform your warehouse into a compliant and efficient operation.