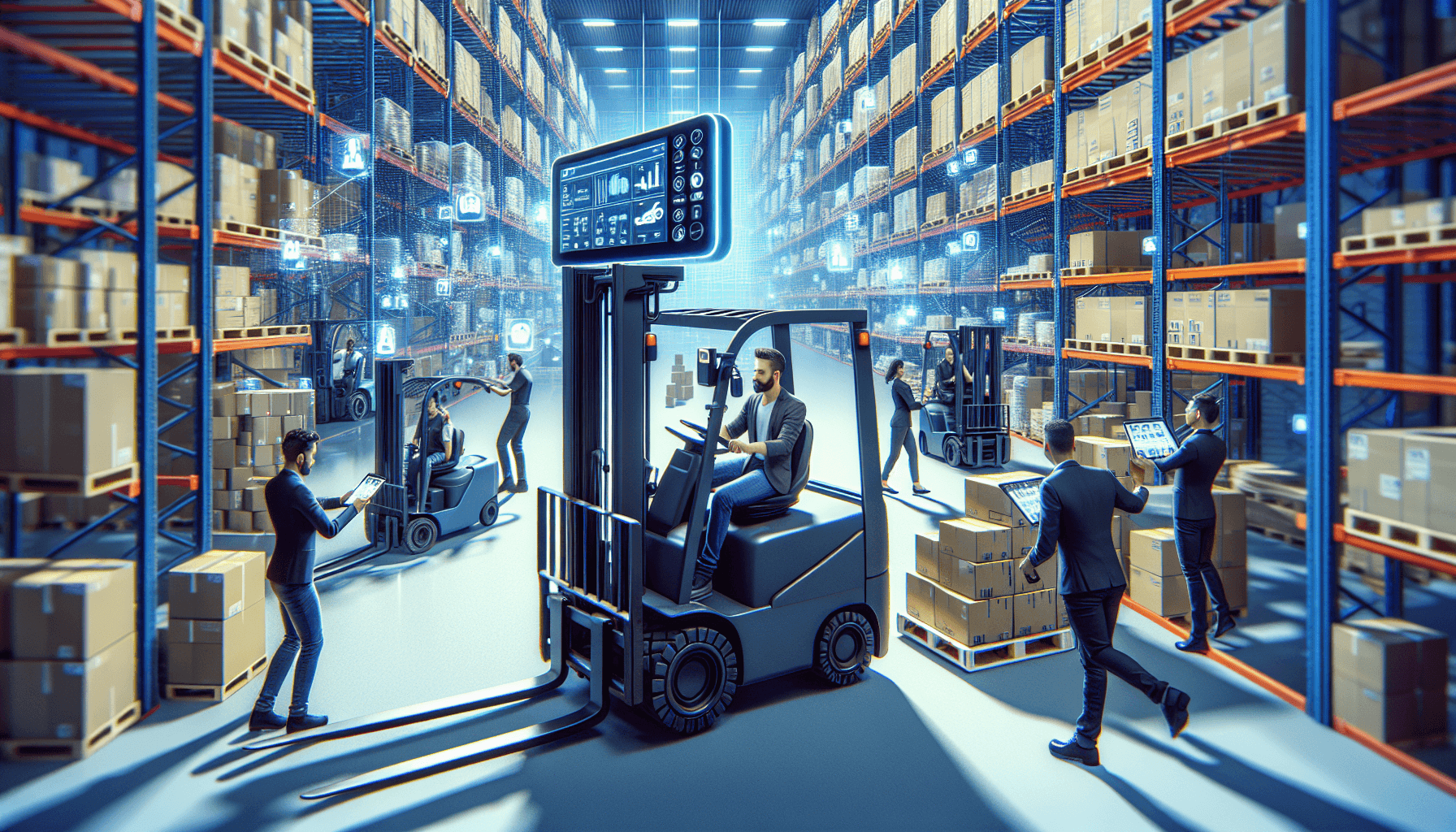

In the fast-paced world of warehouse operations, businesses are constantly seeking ways to gain a competitive advantage. One often overlooked area that plays a crucial role in achieving this advantage is forklift fleet management. Effective management of forklifts can lead to improved safety, increased productivity, and enhanced efficiency. In this article, we will delve into the importance of forklift fleet management in gaining a competitive edge.

Enhancing Safety

Ensuring the safety of employees should be the top priority for any warehouse operation. Forklifts, with their heavy loads and potential for accidents, can pose a significant safety risk. Proper forklift fleet management can help mitigate these risks and create a safer work environment.

By implementing comprehensive forklift training programs, operators can be equipped with the necessary skills and knowledge to operate the vehicles safely. Regular inspections and maintenance schedules can also help identify and address any potential safety issues before they escalate. Additionally, today’s advanced forklift fleet management systems can provide real-time monitoring of operator behaviors, such as speeding or improper usage, allowing immediate corrective action to be taken.

By prioritizing safety through effective forklift fleet management, businesses can reduce the likelihood of accidents, injuries, and potential liabilities, which can ultimately impact the bottom line.

Increasing Productivity

A well-managed forklift fleet can significantly increase productivity within a warehouse. By optimizing forklift utilization, businesses can minimize downtime and ensure that the right equipment is available when needed.

Forklift fleet management systems can track the usage and availability of each forklift, allowing managers to make informed decisions about vehicle allocation. This not only reduces waiting times for operators but also eliminates the need for excessive manual coordination, streamlining operations in the process.

Furthermore, through centralized monitoring and reporting, managers can identify areas of inefficiency, such as routes that require frequent detours or unnecessary travel distances. By addressing these inefficiencies, businesses can optimize their warehouse layout and improve overall workflow, leading to increased productivity.

Additionally, forklift fleet management systems can provide valuable data on key performance indicators, such as number of loads moved per hour or operator productivity. This data can help identify areas for improvement and implement targeted training programs to enhance productivity even further.

Optimizing Efficiency

Efficiency is a critical factor in warehouse operations. By properly managing their forklift fleet, businesses can optimize efficiency and reduce unnecessary costs.

Forklift fleet management systems can automate processes such as maintenance scheduling, reducing manual work and ensuring that vehicles are properly maintained. Regular maintenance not only extends the lifespan of forklifts but also reduces the likelihood of unexpected breakdowns that can disrupt operations.

Moreover, efficient forklift fleet management can help businesses minimize fuel consumption by identifying fuel-efficient routing and implementing preventive measures to reduce idle time. By monitoring fuel usage and implementing best practices, businesses can save significant costs in the long run.

Furthermore, by leveraging the data collected through forklift fleet management systems, businesses can gain insights into their operations and make informed decisions about fleet size and equipment upgrades. By aligning their forklift fleet with the specific needs of their business, companies can optimize efficiency and reduce unnecessary overhead expenses.

Forklift fleet management plays a critical role in securing a competitive advantage in the warehouse industry. By prioritizing safety, increasing productivity, and optimizing efficiency, businesses can elevate their operations and achieve success in an increasingly competitive marketplace.