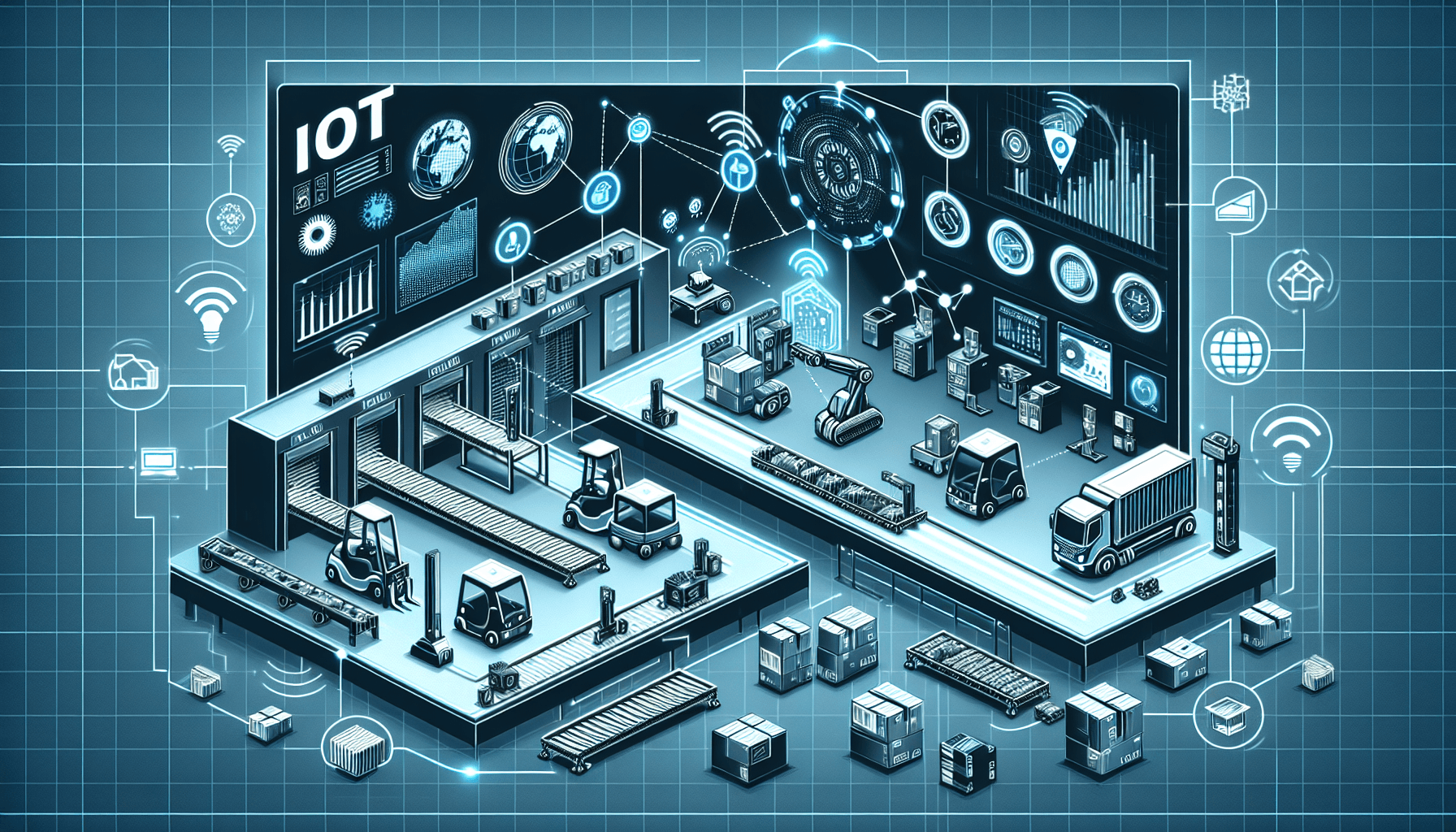

With the ever-evolving landscape of warehouse operations, it becomes crucial for businesses to seek innovative solutions that enhance safety, productivity, efficiency, and cost-effectiveness. One of the transformative technologies that have revolutionized the warehouse industry is the Internet of Things (IoT).

The Impact of IoT on Material Flow Management

The efficient management of material flow is a key component of warehouse optimization. It involves the movement of goods through various stages of the supply chain, from receiving to storage, picking, packing, and shipping. Traditionally, these processes required manual labor and were prone to errors and inefficiencies. However, with the implementation of IoT in warehouse operations, material flow management has reached new heights of efficiency and effectiveness.

The IoT refers to a network of interconnected devices embedded with sensors, software, and connectivity, enabling them to collect and exchange data. In the context of warehouse operations, IoT devices include sensors, RFID tags, beacons, and other smart devices that gather real-time data on inventory, equipment, and environmental conditions. This data can then be analyzed and used to optimize material flow management.

One of the significant advantages of IoT in material flow management is improved visibility and tracking. By deploying IoT devices throughout the warehouse, businesses can gain real-time insights into the exact location and status of each item in their inventory. This eliminates the need for manual tracking, reduces the risk of errors, and allows for prompt decision-making.

Furthermore, the IoT enables businesses to automate various processes in material flow management. For instance, IoT-enabled sensors can monitor inventory levels and automatically trigger replenishment orders when stock reaches a certain threshold. This automation reduces manual intervention, streamlines operations, and prevents stockouts, ultimately contributing to improved customer satisfaction.

The utilization of IoT in material flow management also enhances safety within the warehouse. With real-time data on environmental conditions such as temperature, humidity, and air quality, businesses can proactively address any potential risks or hazards. This ensures the quality and integrity of products and protects the well-being of warehouse personnel.

Another notable benefit of IoT is predictive maintenance. By equipping equipment and machinery with sensors, businesses can monitor their performance in real-time and detect any anomalies or signs of malfunction. This allows for proactive maintenance and reduces the likelihood of unexpected breakdowns or costly repairs. Ultimately, predictive maintenance helps optimize uptime, extend the lifespan of equipment, and minimize operational disruptions.

It is also important to highlight the role of data analytics in optimizing material flow management through IoT. The vast amount of data collected by IoT devices can be processed and analyzed to identify patterns, trends, and areas for improvement. By leveraging advanced analytics and machine learning algorithms, businesses can gain actionable insights to optimize workflows, reduce bottlenecks, and optimize resource allocation.

However, it is crucial for businesses to carefully plan and implement IoT solutions for material flow management. This involves considering factors such as the compatibility of existing systems, the scalability of IoT infrastructure, and cybersecurity measures to protect sensitive data.

At HCO Innovations, we recognize the immense potential of IoT in transforming warehouse operations. With our expertise in warehouse optimization, we can assist businesses in harnessing the power of IoT for material flow management. Our team of professionals can conduct a comprehensive material flow evaluation, identifying opportunities for improvement and implementing tailored IoT solutions to streamline operations and drive business growth.

If you are interested in enhancing your warehouse’s material flow management with IoT, contact us today to schedule a consultation.

In conclusion, the integration of IoT in material flow management brings numerous benefits to warehouse operations. From improved visibility and tracking to automation, safety enhancements, predictive maintenance, and data analytics, IoT revolutionizes the way businesses optimize their material flow processes. By leveraging the power of IoT, businesses can enhance productivity, efficiency, and cost-effectiveness, ultimately gaining a competitive edge in the rapidly evolving warehouse industry.