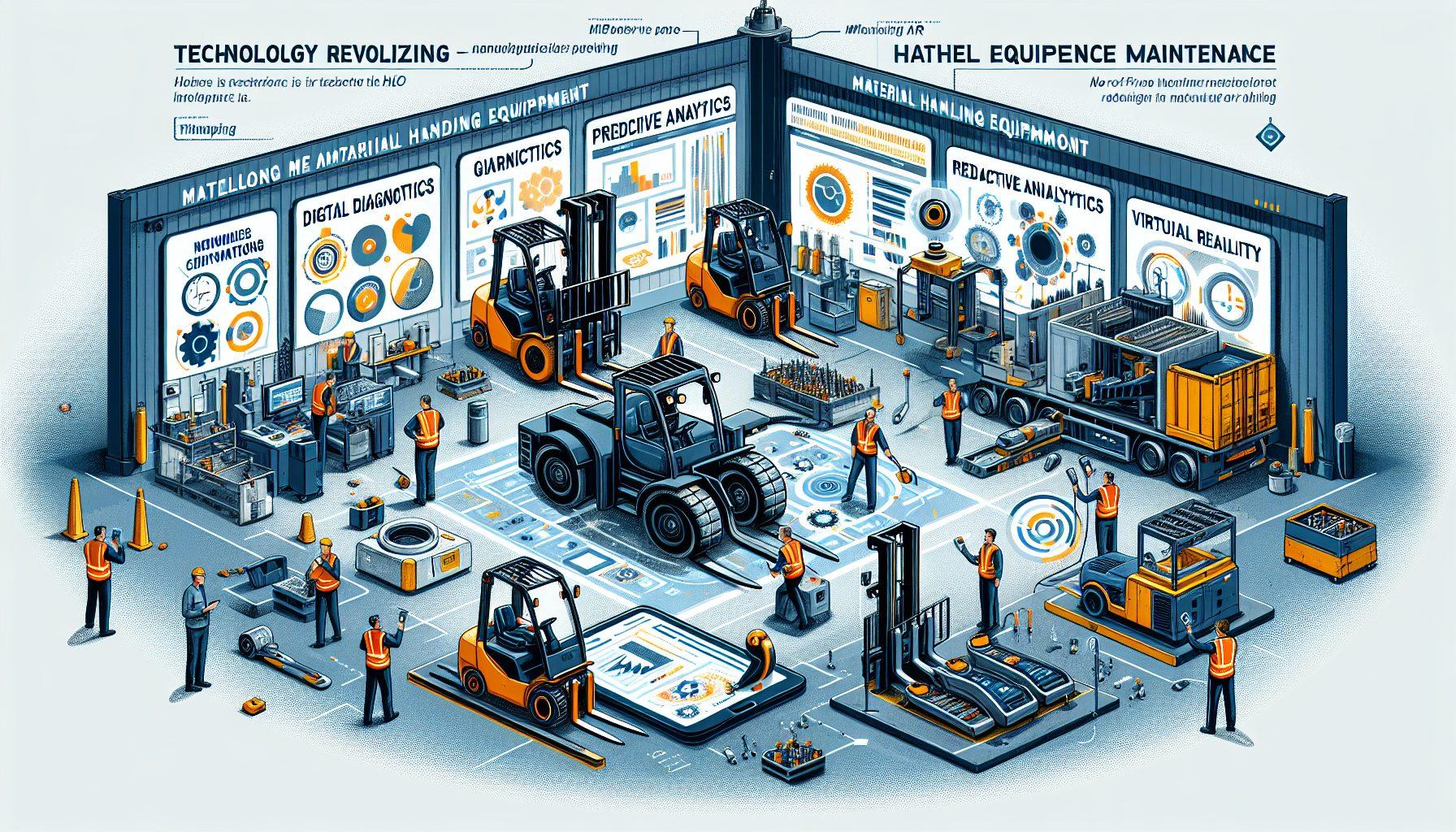

In today’s rapidly evolving warehouse industry, the role of technology in enhancing and optimizing various aspects of operations has become increasingly evident. One area where technology is making a significant impact is in Material Handling Equipment (MHE) maintenance. With advances in technology, warehouse managers and operators can now leverage innovative solutions to effectively manage and maintain their MHE fleet.

The Importance of Proper MHE Maintenance

Material Handling Equipment, such as forklifts, pallet jacks, and reach trucks, are critical to the smooth functioning of warehouse operations. They enable efficient movement and transportation of goods, contributing to increased productivity and reduced labor costs. However, like any other machinery, MHE requires regular maintenance and servicing to ensure optimal performance, longevity, and most importantly, safety.

Proper maintenance of MHE equipment offers several advantages for warehouse operations:

- Enhanced Safety: Well-maintained equipment reduces the risk of accidents, ensuring a safe working environment for employees.

- Optimized Performance: Regular maintenance helps to identify and address issues promptly, preventing breakdowns and maximizing equipment efficiency.

- Reduced Downtime: Proactive maintenance minimizes unexpected equipment failures, resulting in uninterrupted operations and increased productivity.

- Extended Lifespan: Regular servicing and inspections extend the lifespan of MHE, reducing the need for frequent replacements and associated costs.

Traditionally, MHE maintenance involved manual checklists, periodic inspections, and reactive maintenance. However, with the advent of technology, warehouse operators now have access to advanced tools and systems that streamline the entire maintenance process.

Technology-Driven MHE Maintenance Solutions

Warehouse optimization companies like HCO Innovations offer comprehensive MHE maintenance solutions powered by innovative technologies. These solutions leverage the power of data analysis, predictive algorithms, and real-time monitoring to ensure that MHE equipment operates at its highest potential.

Here are some key technology-driven solutions transforming MHE maintenance:

- Telematics and IoT: By integrating telematics and IoT (Internet of Things) devices with MHE equipment, warehouse operators can gather real-time data on equipment health, utilization, and performance. This data enables proactive monitoring, early fault detection, and predictive maintenance.

- Preventive Maintenance Software: Advanced maintenance software allows warehouse managers to schedule and track maintenance tasks, generate automated work orders, and maintain a comprehensive maintenance history for each equipment. This streamlines the maintenance process and ensures that no maintenance task is overlooked.

- Condition Monitoring: Sensor-based monitoring systems placed on MHE equipment can continuously collect data on various parameters such as temperature, vibration, and usage. This data is then analyzed to detect anomalies, identify potential issues, and trigger timely maintenance interventions.

- Remote Diagnostics: With remote diagnostic capabilities, technicians can troubleshoot and diagnose MHE equipment issues remotely, reducing the need for costly on-site visits. This saves time and allows for quicker resolution of problems, minimizing equipment downtime.

By utilizing these technology-driven solutions, warehouse operators can take a proactive approach to MHE maintenance, effectively reducing the likelihood of unexpected breakdowns and optimizing the overall performance of their equipment fleet.

The Benefits of Technology-Driven MHE Maintenance

Implementing technology-driven solutions for MHE maintenance offers numerous benefits for warehouse operators:

- Improved Cost-Efficiency: Proactive maintenance helps prevent major breakdowns and costly repairs, resulting in reduced maintenance costs over time.

- Increased Productivity: Reliable MHE equipment ensures uninterrupted operations, leading to increased productivity and streamlined workflows.

- Enhanced Compliance: Some software solutions offer compliance features that help warehouse operators stay on top of maintenance schedules and regulatory requirements.

- Optimized Resource Allocation: Data-driven insights enable warehouse managers to allocate resources effectively, ensuring that maintenance tasks are carried out efficiently without disrupting operations.

With technology-driven solutions, warehouse operators can establish a culture of proactive maintenance that saves time, reduces costs, and enhances the overall efficiency of their operations.

To conclude, it is clear that technology plays a vital role in revolutionizing MHE maintenance in warehouse operations. By embracing innovative solutions offered by companies like HCO Innovations, warehouse operators can harness the power of technology to ensure the longevity, safety, and optimal performance of their MHE fleet. To learn more about HCO Innovations’ Material Handling Equipment Management solutions, visit their website.