Technology is constantly evolving and transforming various industries, and the field of material handling equipment is no exception. With the advent of new technologies, warehouse operations have become more efficient, productive, and cost-effective. In this article, we will explore the impact of technology on material handling equipment efficiency and how companies can benefit from embracing these advancements.

Automation and Robotics

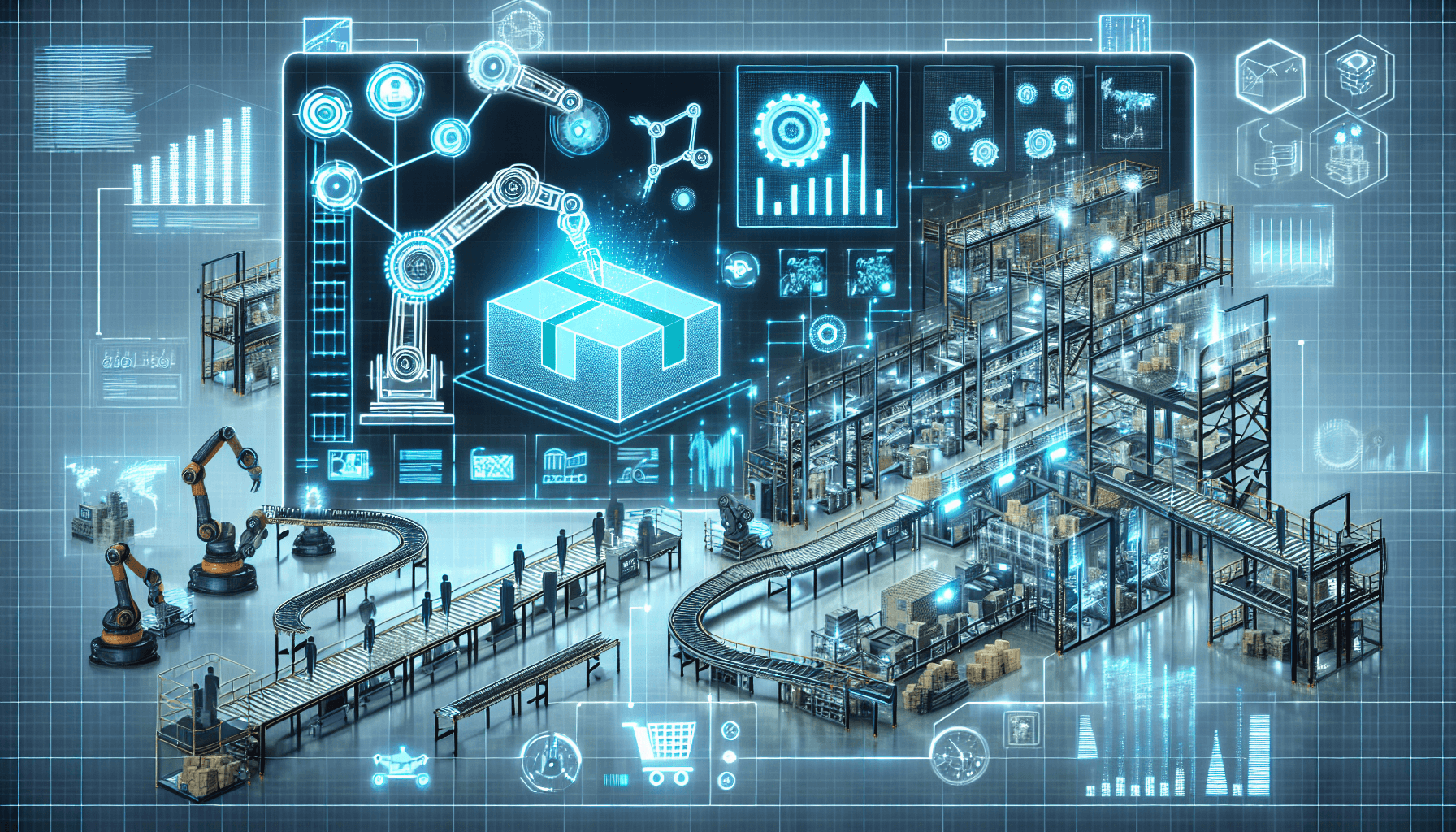

One of the key advancements in material handling equipment is the integration of automation and robotics. Automated systems such as conveyor belts, automated storage and retrieval systems (AS/RS), and robotic arms have significantly improved the speed and accuracy of material handling tasks. These technologies streamline the movement of goods within a warehouse, minimizing manual errors and reducing the risk of injuries.

The integration of robotics in material handling equipment has also brought about increased flexibility and scalability. Robots can be programmed to handle a wide range of tasks, from picking and packing to loading and unloading goods. Additionally, robots can work 24/7 without the need for breaks, resulting in improved productivity and throughput.

Software solutions have also played a crucial role in optimizing material handling equipment. Warehouse management systems (WMS) and warehouse control systems (WCS) allow for real-time tracking and monitoring of inventory, helping companies to effectively manage their stock levels and reduce the occurrence of stockouts. These software solutions also enable efficient inventory forecasting and replenishment, ensuring that the right products are available at the right time, reducing the risk of delays or shortages.

Data Analytics and Optimization

Another area where technology has made a significant impact on material handling equipment efficiency is data analytics and optimization. By collecting and analyzing data from various sources such as sensors, barcode scanners, and RFID tags, companies can gain valuable insights into their warehouse operations.

Real-time data analytics allows warehouse managers to identify bottlenecks, optimize workflows, and make informed decisions to improve overall efficiency. For example, by analyzing data on order picking time and storage utilization, managers can identify areas of improvement and implement strategies to reduce travel time, optimize pick paths, and maximize storage space.

Furthermore, predictive analytics can be used to anticipate maintenance requirements for material handling equipment. By monitoring equipment performance metrics, companies can schedule proactive maintenance tasks, minimizing downtime and reducing the risk of costly breakdowns. This ensures that equipment is always in optimal condition, leading to improved efficiency and productivity.

Training and Safety

Technology has also revolutionized training and safety in material handling equipment operations. Virtual reality (VR) and augmented reality (AR) technologies have emerged as valuable tools for training warehouse personnel in handling equipment safely and efficiently.

VR and AR simulations provide a realistic and immersive environment where employees can practice operating equipment without the risk of accidents or damage. These technologies allow for training in various scenarios, such as forklift operation, pallet stacking, or operating an AS/RS system. By training employees in a virtual environment, companies can ensure that they are competent and confident in their operations, leading to improved safety and reduced errors.

The integration of technology in material handling equipment has also introduced advanced safety features. Sensors, cameras, and proximity detection systems help prevent collisions and accidents by alerting operators to potential hazards. Automatic emergency braking systems, anti-slip surfaces, and ergonomic designs further enhance the safety of material handling equipment, reducing the risk of injuries and improving overall workplace safety.

In conclusion, the impact of technology on material handling equipment efficiency has been substantial. Automation and robotics have improved productivity and accuracy, while software solutions have enhanced inventory management and control. Data analytics and optimization enable companies to make informed decisions and optimize workflows. Training and safety have been revolutionized by VR, AR, and advanced safety features. Embracing these technological advancements can significantly benefit companies by improving safety, productivity, efficiency, and cost-effectiveness within their warehouse operations.

If you are interested in learning more about material handling equipment management, please visit HCO Innovations.