Material handling equipment plays a significant role in warehouse operations. From forklifts to conveyor systems, these tools and technologies are essential for ensuring the smooth flow of goods within a warehouse. As technology continues to advance at a rapid pace, the material handling equipment industry is not far behind. In this article, we will explore the top trends in material handling equipment technology that are shaping the industry today.

1. Automation

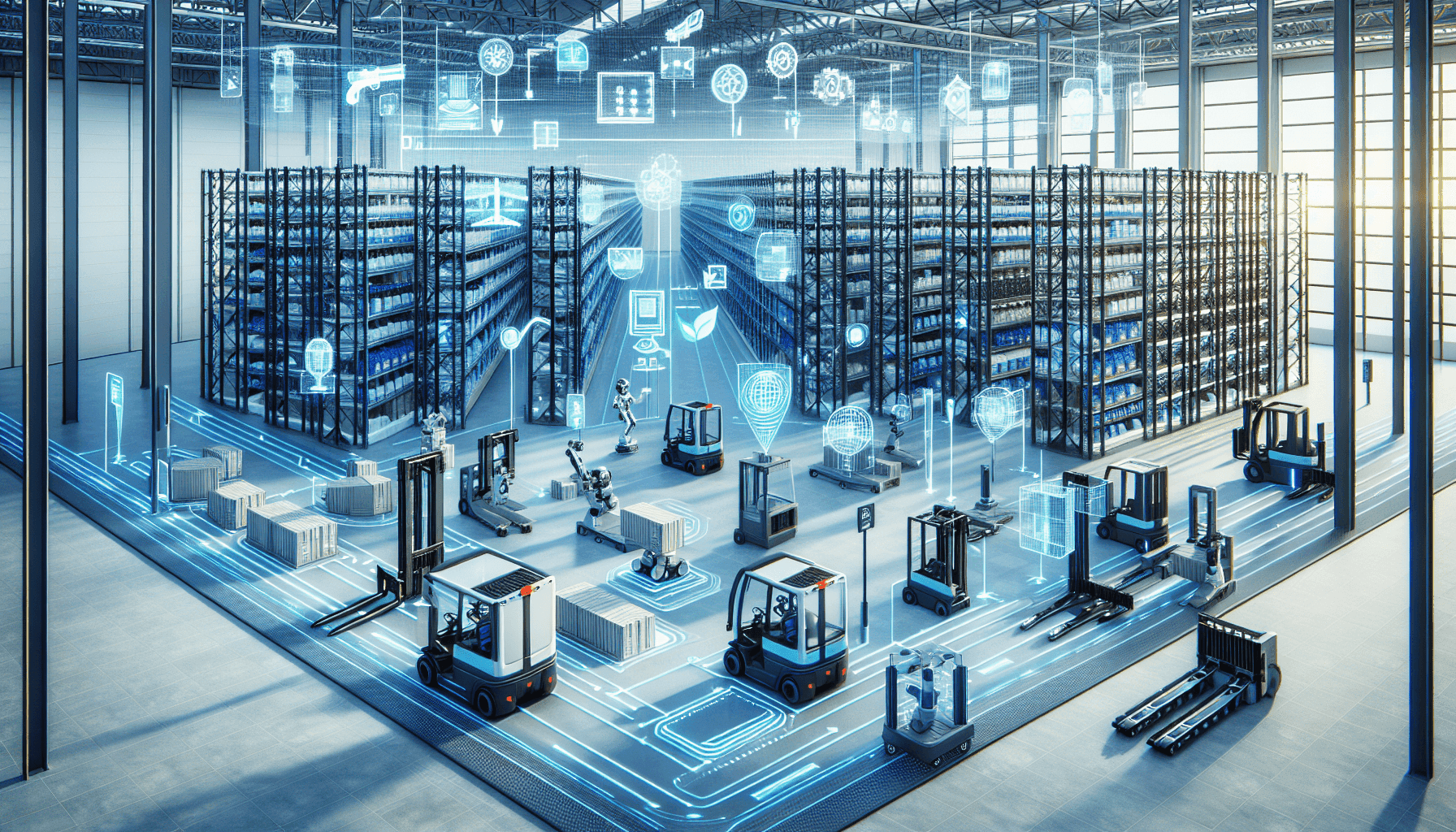

Automation has been a game-changer in various industries, and material handling is no exception. With the advent of advanced robotics and AI-powered systems, warehouses are becoming more automated than ever before. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are replacing manual labor in tasks such as picking, packing, and transportation. These machines can navigate through the warehouse using advanced sensors and algorithms, optimizing efficiency and reducing human error.

Additionally, warehouse management systems (WMS) are being integrated with automation technologies, allowing for seamless coordination and control over various material handling equipment. This integration leads to improved productivity, reduced costs, and enhanced safety in warehouse operations.

2. Internet of Things (IoT)

The Internet of Things (IoT) has revolutionized many industries, and it is now making its mark in material handling equipment technology. IoT-enabled devices and sensors are being integrated into forklifts, shelving units, and other equipment, enabling real-time tracking and monitoring of inventory and equipment performance.

Connected material handling equipment can provide valuable data on usage patterns, operational efficiency, and maintenance needs. This data can be analyzed to identify opportunities for improvement and preventive maintenance. Warehouse managers can make data-driven decisions to optimize fleet performance, reduce downtime, and enhance overall warehouse productivity.

3. Augmented Reality (AR)

Augmented Reality (AR) is not just limited to gaming and entertainment; it is also finding applications in the material handling industry. AR technology can be used to provide warehouse operators with real-time information and visual guidance, enhancing their efficiency and accuracy.

For example, AR glasses can display information about the location of inventory, pick-lists, and navigation routes to warehouse workers. This information is superimposed onto the worker’s field of view, allowing them to keep their hands free and reduce the time required to locate items. AR technology can also assist in training new employees by providing interactive tutorials and simulations.

4. Predictive Analytics

Predictive analytics is becoming increasingly important in material handling equipment management. By leveraging machine learning algorithms, warehouse managers can analyze historical and real-time data to predict equipment failures and maintenance needs.

For example, sensors embedded in forklifts can monitor variables such as temperature, vibration, and energy consumption. By analyzing patterns in this data, predictive maintenance models can identify potential issues before they escalate into major breakdowns. This helps reduce the risk of costly downtime and extends the lifespan of equipment.

5. Cloud Computing

Cloud computing is playing a crucial role in the evolution of material handling equipment technology. Cloud-based warehouse management systems (WMS) allow for centralized data storage and real-time access from anywhere, improving collaboration and decision-making.

Warehouse managers can monitor inventory, track equipment performance, and generate reports remotely through web-based interfaces. Cloud-based systems also facilitate integration with other enterprise systems such as ERP, ensuring seamless data flow across the organization.

Learn more about material handling equipment management solutions.

In conclusion, the material handling equipment industry is embracing various technological advancements to enhance productivity, efficiency, and cost-effectiveness in warehouse operations. From automation and IoT to augmented reality and predictive analytics, these trends are shaping the future of material handling. By adopting and implementing these technologies, warehouse managers can stay ahead of the competition and optimize their operations for success.