Warehouse layout design plays a crucial role in the overall efficiency and productivity of a warehouse operation. It involves organizing the physical space in a way that maximizes storage capacity, enhances workflow, and promotes safety. An effective warehouse layout can significantly improve operational processes, minimize errors, and increase cost-effectiveness.

The Benefits of Effective Warehouse Layout Design

A well-designed warehouse layout offers numerous benefits to businesses. Let’s explore some of the key advantages:

- Optimized Space Utilization: Efficient warehouse layout design allows for better utilization of available space. By arranging storage racks, shelving, and other equipment in an organized and strategic manner, businesses can maximize their storage capacity. This means being able to store more products within the same square footage, reducing the need for additional warehouse space.

- Improved Workflow: The layout of a warehouse directly impacts the flow of materials and products. By designing a layout that minimizes the distance between different workstations, storage areas, and picking stations, businesses can streamline their operations and reduce unnecessary movement. This leads to faster turnaround times, increased productivity, and improved order fulfillment.

- Enhanced Safety: Warehouse safety is of paramount importance. A well-designed layout takes into account safety measures such as clear paths for forklifts, properly marked pedestrian walkways, and designated areas for hazardous materials. By optimizing the layout for safety, businesses can reduce the risk of accidents, injuries, and damage to products or equipment.

- Reduced Costs: An effective warehouse layout can lead to cost savings in various ways. By improving workflow and minimizing the distance traveled by employees and equipment, businesses can save on labor costs. Additionally, optimized space utilization reduces the need for additional storage space, saving on rent or construction expenses. Ultimately, a well-designed warehouse layout can contribute to overall cost-effectiveness.

Click here to learn more about warehouse layout evaluation.

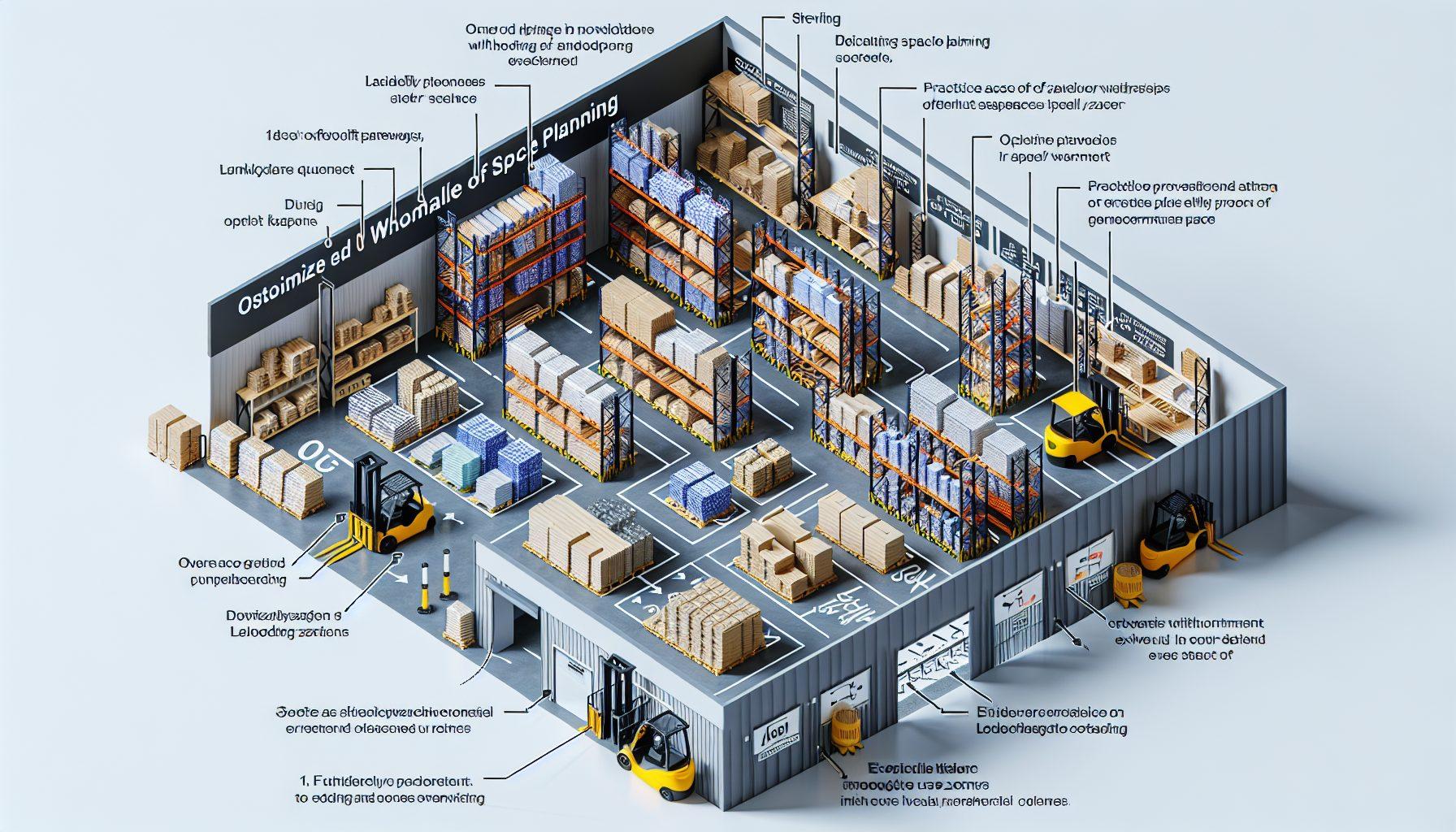

Space Planning Considerations in Warehouse Layout Design

When it comes to designing an efficient warehouse layout, space planning is a critical aspect. Space planning involves carefully considering various factors to ensure optimal space utilization. Let’s look at some key considerations:

- Product Accessibility: One of the primary objectives of space planning is to ensure easy access to products. High-velocity items that are frequently accessed should be strategically located near the shipping area or picking stations to minimize travel time. Slower-moving items can be placed further away to avoid congestion and ensure efficient use of space.

- Storage Equipment: The choice of storage equipment has a significant impact on warehouse layout design. Different types of storage systems, such as pallet racks, mezzanine floors, or automated systems, have unique space requirements. It’s essential to select the right storage equipment based on factors such as the type of products, their dimensions, weight, and handling requirements.

- Future Scalability: When designing a warehouse layout, it’s crucial to consider future growth and scalability. Businesses should account for potential expansion or changes in product lines and plan the layout in a way that allows for easy adjustments. This flexibility helps avoid the need for major layout changes down the line, saving both time and money.

- Ergonomics: Ensuring ergonomic workspaces is vital for employee well-being and productivity. Space planning should consider factors such as aisle widths, workstation heights, and the placement of equipment to minimize strain and fatigue. A well-designed layout takes into account ergonomic principles to create a comfortable and safe working environment.

- Compliance with Regulations: Warehouses must comply with various safety and regulatory standards. Space planning should consider these requirements, including fire safety codes, building regulations, and environmental regulations. Adhering to these guidelines ensures the warehouse operates within legal parameters while prioritizing the well-being of employees and the environment.

Effective space planning is crucial for optimizing warehouse layout design. It requires a deep understanding of the business’s specific requirements, products, and operational processes. Investing in professional warehouse optimization solutions, such as those offered by HCO Innovations, can provide businesses with expert guidance and innovative strategies to achieve an efficient and cost-effective warehouse layout.

Conclusion

Warehouse layout design is a critical component of optimizing warehouse operations. By implementing an effective layout, businesses can maximize space utilization, enhance workflow, improve safety, and reduce costs. Through strategic space planning considerations and professional warehouse optimization solutions, businesses can unlock the full potential of their warehouse operations.