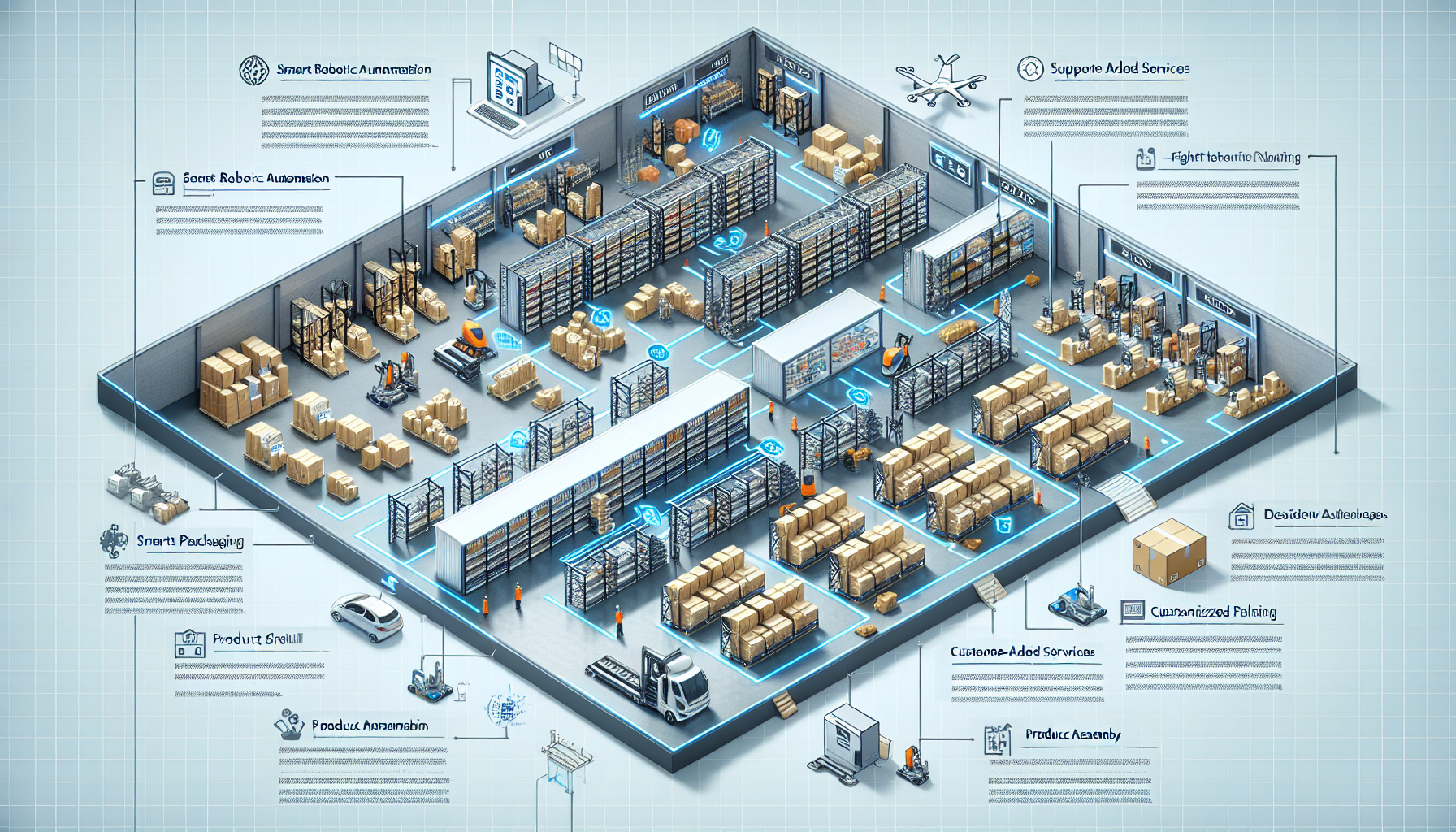

Creating an efficient warehouse layout is crucial for businesses looking to optimize their operations and provide value-added services to their customers. A well-designed warehouse layout not only enhances safety and productivity but also improves efficiency and cost-effectiveness. In this article, we will explore how to create a warehouse layout that supports value-added services.

Understanding Value-Added Services

Value-added services are additional services offered by businesses to provide added benefits to their customers. In the context of warehousing, value-added services can include packaging, labeling, kitting, assembly, customization, and more. These services go beyond the basic storage and distribution of goods and can help businesses differentiate themselves from the competition.

When designing a warehouse layout to support value-added services, it’s essential to have a comprehensive understanding of the services you plan to offer. This includes identifying the specific requirements for each service, such as space, equipment, and manpower. Once you have a clear understanding of the services, you can optimize your warehouse layout to accommodate them effectively.

Optimizing Space Allocation

One of the key elements in creating a warehouse layout for value-added services is optimizing space allocation. Efficient space utilization allows for seamless workflow and reduces the risk of bottlenecks or congestion. Here are some strategies to consider:

- Categorize products based on their storage requirements, such as temperature-controlled areas for perishable goods or secure areas for high-value items.

- Implement a bin location system to easily locate and retrieve specific products, reducing the time wasted searching for items.

- Designate specific zones for value-added services, ensuring there is enough space for activities like packaging, labeling, or assembly.

- Implement vertical storage solutions, such as mezzanine floors or high-rise racking, to make the most of the available vertical space.

Streamlining Workflow

To provide efficient value-added services, it’s essential to streamline the workflow within your warehouse. This involves careful planning and organization to ensure smooth and timely execution of tasks. Consider the following strategies:

- Design a logical flow for goods, from receiving to storage, value-added services, and outbound shipping.

- Implement a barcode or RFID system for inventory management, enabling accurate and real-time tracking of products throughout the warehouse.

- Arrange workstations strategically, placing value-added service areas close to the storage areas to minimize unnecessary movement.

- Invest in automation technologies, such as conveyor systems or robotic pickers, to streamline processes and reduce human error.

Ensuring Safety Measures

Creating a warehouse layout that supports value-added services must prioritize safety measures to protect both employees and products. Here are some important considerations:

- Ensure proper lighting and ventilation throughout the warehouse to create a safe working environment.

- Implement safety protocols and train employees on proper handling procedures to prevent accidents and injuries.

- Designate separate areas for hazardous materials, following all relevant safety regulations and guidelines.

- Install safety equipment, such as fire extinguishers and emergency exit signs, at easily accessible locations.

By prioritizing safety, businesses can create a conducive environment for employees to perform value-added services effectively while minimizing the risk of accidents or damages.

Constant Evaluation and Improvement

Creating a warehouse layout that supports value-added services is an ongoing process that requires regular evaluation and improvement. As your business grows and evolves, so will your warehouse requirements. Here are some practices to follow:

- Regularly evaluate the efficiency of your warehouse layout and make necessary adjustments to optimize space utilization and workflow.

- Seek feedback from employees involved in value-added services to identify potential bottlenecks or areas for improvement.

- Stay updated on industry trends and advancements in warehouse management technology to leverage new tools and techniques.

- Consider partnering with a warehouse optimization solutions provider, like HCO Innovations, to receive expert advice and assistance in creating a tailored warehouse layout.

HCO Innovations can help businesses create a warehouse layout that optimizes space, streamlines workflow, and ensures safety while supporting value-added services. With their expertise in warehouse optimization solutions, businesses can enhance their operations and provide exceptional services to their customers.

In conclusion, creating a warehouse layout that supports value-added services requires careful planning, optimization, and constant evaluation. By allocating space efficiently, streamlining workflow, prioritizing safety, and continually seeking improvement, businesses can create a warehouse layout that drives value and sets them apart from the competition.