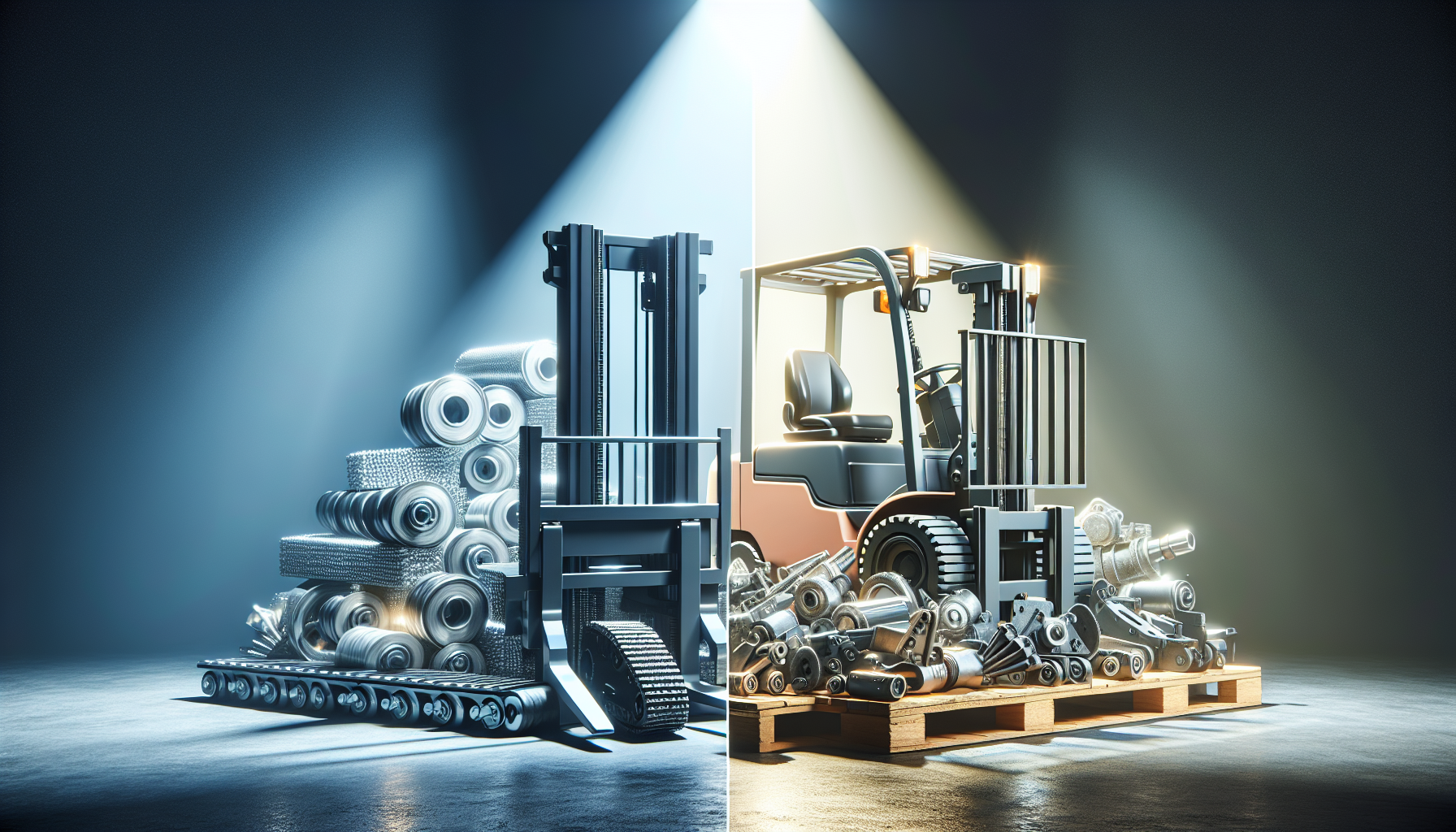

When it comes to optimizing your warehouse operations, one crucial aspect to consider is the choice between new and used material handling equipment. Material handling equipment plays a vital role in ensuring the smooth flow of goods within your warehouse, enhancing productivity and efficiency. However, deciding whether to invest in new or used equipment can be a challenging decision. In this article, we will explore the key factors to consider when choosing between new and used material handling equipment to help you make an informed decision for your warehouse.

Reliability and Performance

Reliability and performance are crucial considerations when it comes to choosing material handling equipment. New equipment offers the advantage of being brand new and unused, typically backed by a manufacturer’s warranty. This assurance of quality and reliability can be beneficial in ensuring smooth operations and minimizing downtime. New equipment is also likely to offer the latest technological advancements, which can enhance performance and efficiency.

On the other hand, used equipment may have a lower upfront cost but may come with the risk of potential wear and tear. It is important to thoroughly inspect used equipment and understand its maintenance history before making a purchasing decision. By choosing a reputable provider like HCO Innovations, who specializes in warehouse optimization solutions, you can ensure that any used equipment you purchase has been properly tested and inspected, minimizing the risk of reliability issues.

Cost Considerations

Cost is another major factor to consider when choosing between new and used material handling equipment. New equipment generally comes with a higher upfront cost compared to used equipment. However, it is important to consider the long-term costs and potential return on investment.

New equipment tends to have a longer lifespan and can offer better efficiency, reducing operating costs in the long run. In addition, new equipment may require less frequent maintenance and repairs, saving on ongoing expenses. Used equipment, although offering a more affordable initial cost, may require more frequent maintenance and repairs, which can add up over time.

It is crucial to evaluate your specific needs, budget, and projected usage before making a decision. By analyzing factors such as expected lifespan, maintenance costs, and potential resale value, you can determine whether the upfront cost of new equipment outweighs the potential savings of used equipment.

Availability and Customizability

Another consideration when choosing material handling equipment is availability and customizability. New equipment is generally readily available from manufacturers and suppliers, offering a wide range of models, sizes, and features to choose from. This allows you to select equipment that specifically meets your warehouse needs and requirements. Additionally, new equipment can often be customized or tailored to fit your unique warehouse layout and operations.

Used equipment, on the other hand, may have more limited availability and customization options. The selection of used equipment can vary depending on the market and availability of pre-owned equipment. However, with a reputable provider like HCO Innovations, you can still access a wide range of high-quality used equipment that has been refurbished and fully tested.

It is important to assess your specific warehouse requirements and weigh the availability and customizability options before making a decision. Consider factors such as the size of your warehouse, the type of goods being handled, and any specific features or functionalities that are essential for your operations.

Environmental Considerations

In recent years, sustainability and environmental considerations have become increasingly important for businesses. Choosing used material handling equipment can contribute to sustainability efforts by reducing the demand for new manufacturing and limiting waste. By investing in refurbished and properly maintained equipment, you are extending its lifespan and minimizing environmental impact.

However, it is important to note that new equipment may incorporate the latest energy-efficient technologies, reducing energy consumption and carbon footprint. It is essential to balance your environmental goals with other factors such as reliability, performance, and long-term costs to make the best decision for your warehouse operations.

In conclusion, choosing between new and used material handling equipment requires careful consideration of various factors. While new equipment offers the benefits of reliability, performance, and customizability, used equipment can be a cost-effective option with potential sustainability advantages. By assessing your specific needs, budget, and long-term goals, you can make an informed decision that aligns with your warehouse optimization objectives. For a wide range of material handling equipment options and expert advice, visit HCO Innovations, where they specialize in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations.