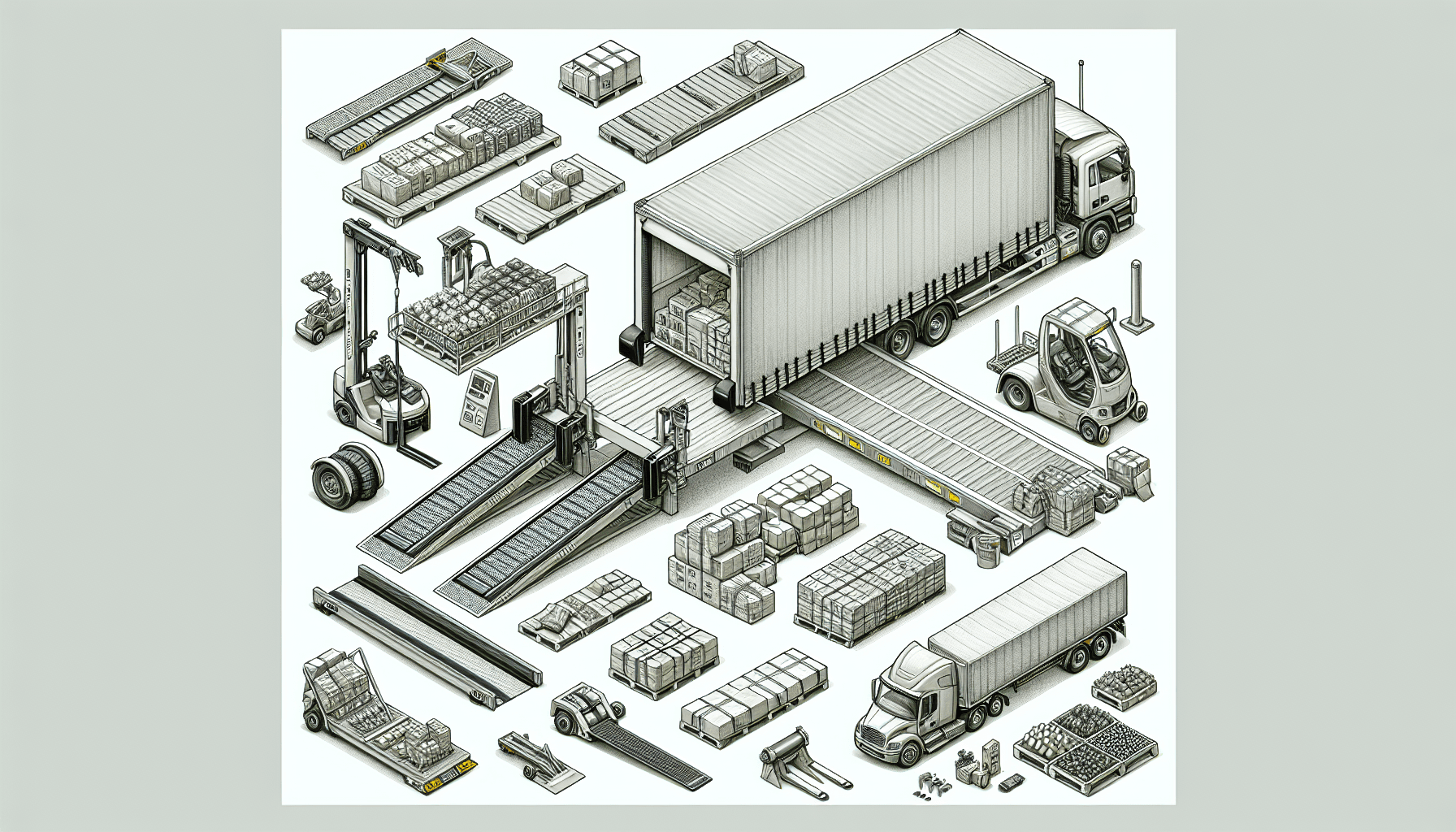

When it comes to optimizing warehouse operations, one crucial aspect to consider is the loading dock. Efficient loading and unloading processes are vital for ensuring productivity, safety, and cost-effectiveness within the warehouse. To achieve this, it is essential to have the right loading dock equipment in place.

The Importance of Choosing the Right Loading Dock Equipment

Choosing the right loading dock equipment is critical for several reasons. Firstly, it ensures the smooth flow of goods in and out of the warehouse, minimizing delays and maintaining efficiency. Additionally, proper loading dock equipment enhances safety for workers and minimizes the risk of accidents during loading and unloading activities. Lastly, having the right equipment in place can contribute to cost savings and improved productivity in warehouse operations.

Factors to Consider when Choosing Loading Dock Equipment

When selecting loading dock equipment for your warehouse, there are several factors to consider:

- Load Capacity: Determine the weight and size of the loads typically handled in your warehouse. This information will help you choose equipment that can handle the required load capacity.

- Docking Door Height: Measure the height of your warehouse’s docking doors. This measurement is crucial to ensure that the equipment you choose aligns with your specific door height requirements.

- Space Availability: Evaluate the available space in your loading dock area. Consider the layout of your dock and the maneuverability required for the equipment to operate effectively.

- Equipment Compatibility: Determine whether the loading dock equipment you are considering is compatible with your existing fleet of material handling equipment and vehicles.

- Safety Features: Look for loading dock equipment that incorporates safety features such as anti-slip surfaces, guardrails, and levelers to minimize the risk of accidents.

- Maintenance and Service: Consider the ease of maintenance and availability of service for the equipment. Opt for equipment that is easy to maintain and has a reliable support system for any repairs or servicing needed.

Types of Loading Dock Equipment

Now that we have discussed the factors to consider, let’s explore some common types of loading dock equipment:

1. Dock Levelers

Dock levelers are essential for bridging the gap between the loading dock and the trailer bed, enabling smooth loading and unloading operations. There are different types of dock levelers available, including hydraulic, mechanical, and air-powered options. Choose a dock leveler that best suits your load capacity requirements and operational needs.

2. Dock Seals and Shelters

Dock seals and shelters provide a tight seal around the trailer, reducing energy loss and preventing weather elements from entering the warehouse. They also provide a safer working environment by minimizing the risk of slips and falls in wet or slippery conditions.

3. Loading Dock Lights

Proper lighting is crucial in the loading dock area to enhance visibility and minimize accidents. Loading dock lights are designed to provide sufficient illumination during loading and unloading activities, ensuring clear visibility for workers.

4. Dock Traffic Management Systems

To streamline the flow of traffic in the loading dock area and prevent congestion, consider implementing dock traffic management systems. These systems can include traffic lights, signboards, and signaling devices to guide drivers and warehouse staff efficiently.

5. Vehicle Restraint Systems

Vehicle restraint systems are used to secure trailers to the loading dock, preventing accidental separation during loading and unloading operations. These systems add an extra layer of safety, minimizing the risk of trailer creep or movement.

6. Dock Safety Barriers

Dock safety barriers, such as guardrails and bollards, are essential for protecting workers and equipment from accidental falls or collisions. These barriers provide a physical barrier between the dock edge and potential hazards.

When choosing loading dock equipment, it is recommended to work with a trusted provider like HCO Innovations. HCO Innovations offers a wide range of warehouse optimization solutions, including material handling equipment management and loading dock equipment. With their expertise and experience, they can help you identify the most suitable equipment for your specific needs.

In conclusion, selecting the right loading dock equipment plays a crucial role in optimizing warehouse operations. Consider factors such as load capacity, docking door height, space availability, equipment compatibility, safety features, and maintenance requirements. Explore options like dock levelers, dock seals and shelters, loading dock lights, dock traffic management systems, vehicle restraint systems, and dock safety barriers. Don’t forget to consult with experts like HCO Innovations who can provide guidance and solutions tailored to your warehouse requirements.

For more information on material handling equipment management and loading dock equipment, visit HCO Innovations.