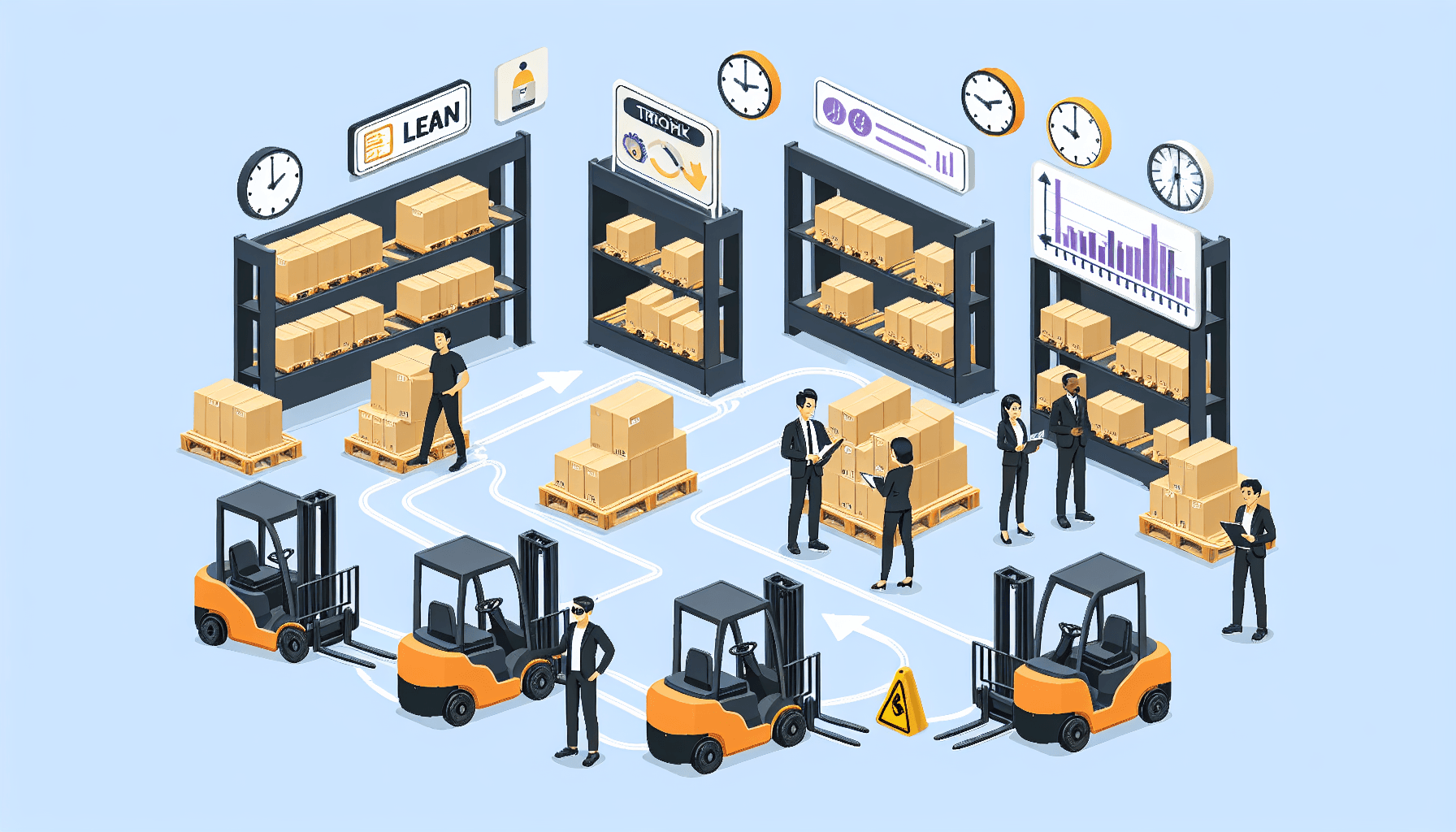

Implementing lean principles in forklift fleet management can greatly enhance operational efficiency, reduce costs, and improve overall productivity. By applying lean methodologies to the management of your forklift fleet, you can streamline processes, eliminate wasteful practices, and optimize your resources. In this article, we will explore how businesses can effectively implement lean principles in forklift fleet management.

1. Assess Current Processes

The first step towards implementing lean principles in forklift fleet management is to assess your current processes. This involves evaluating the entire lifecycle of forklift fleet management, from acquisition and maintenance to utilization and disposal. Identify any bottlenecks, inefficiencies, or areas for improvement within your current processes.

Consider conducting time and motion studies to analyze how forklifts are being used, identify any unnecessary movements or idle time, and determine the most efficient routes. This assessment will provide valuable insights into areas that need improvement and help you identify where lean principles can be applied.

2. Streamline Fleet Acquisition

One area where lean principles can be applied in forklift fleet management is in the acquisition process. Look for opportunities to streamline the purchasing process to minimize lead times, reduce paperwork, and optimize supplier relationships. Consider implementing a vendor management system to centralize vendor information, track performance, and negotiate better terms. This will help you streamline the procurement process and ensure timely availability of forklifts when needed.

Additionally, consider implementing a standardized forklift selection process based on your specific operational requirements. This will help ensure that you only acquire the necessary number and type of forklifts, avoiding overstocking and underutilization.

3. Implement Preventive Maintenance

Maintaining a healthy forklift fleet is crucial for effective fleet management. Implementing a preventive maintenance program can help minimize breakdowns, maximize uptime, and extend the lifespan of your forklifts. Adopting a proactive approach to maintenance will reduce unexpected repairs and downtime, ultimately improving productivity.

Create a detailed maintenance schedule and conduct regular inspections, checks, and servicing of your forklift fleet. Implement a robust tracking system to record maintenance activities, monitor service histories, and identify recurring issues. This will allow you to address maintenance needs promptly and avoid any potential safety hazards.

4. Optimize Utilization and Operator Efficiency

Lean principles can also be applied to optimize the utilization and efficiency of your forklift fleet operators. Ensure that all operators are properly trained and certified to operate forklifts. Implement ongoing training programs to enhance their skills and keep them up to date with the latest industry practices.

Monitor operator performance and track key metrics such as load efficiency, travel time, and fuel consumption. Use this data to identify areas for improvement and implement targeted training and coaching programs. Regularly review and optimize work schedules to ensure optimal utilization of your forklift fleet and minimize idle time.

5. Continuous Improvement and Waste Reduction

Lean principles emphasize the importance of continuous improvement and waste reduction. Encourage a culture of continuous improvement among your forklift fleet management team. Implement regular brainstorming sessions and improvement projects to identify and address any wasteful practices or inefficient processes.

Consider implementing a visual management system to track key performance indicators (KPIs) and display them in a visible location for the entire team to see. This will promote transparency, accountability, and encourage proactive problem-solving.

Conclusion

Implementing lean principles in forklift fleet management can lead to significant improvements in operational efficiency, cost reduction, and overall productivity. By assessing current processes, streamlining fleet acquisition, implementing preventive maintenance, optimizing utilization and operator efficiency, and fostering a culture of continuous improvement, businesses can reap the benefits of lean practices in their forklift fleet management.

If you need assistance with implementing lean principles in your forklift fleet management, consider partnering with a trusted provider like HCO Innovations. With their expertise in forklift fleet management, they can help you optimize your fleet, improve operational efficiency, and achieve your business goals. Learn more about their services here.