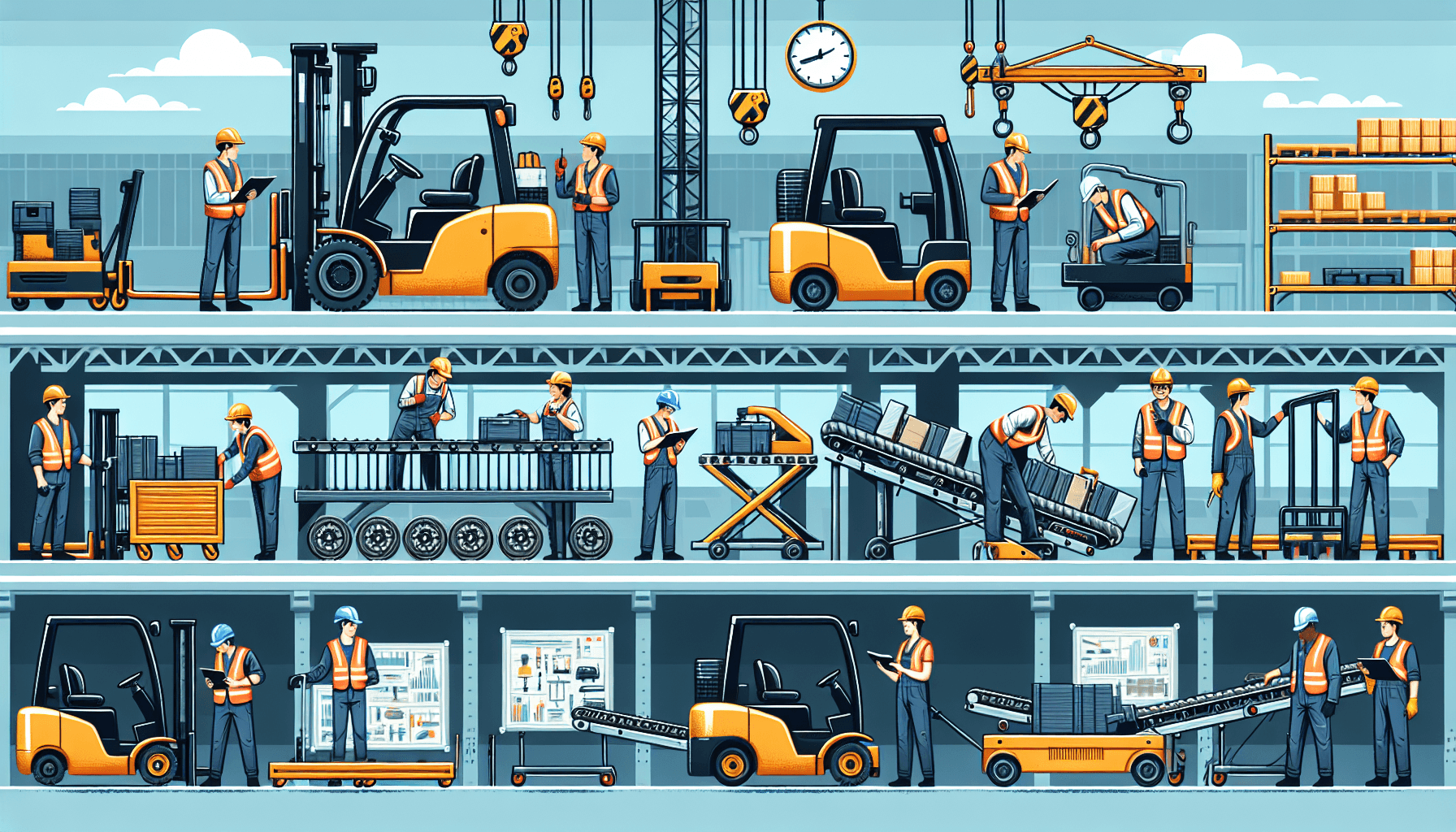

Warehouse optimization is crucial for businesses that rely on efficient and streamlined operations. One of the key components of an optimized warehouse is the proper management of Material Handling Equipment (MHE). MHE includes a wide range of equipment such as forklifts, pallet jacks, and conveyors that are essential for moving, storing, and organizing inventory within a warehouse. In this article, we will explore how to optimize maintenance for different types of MHE.

Regular Maintenance for Forklifts

Forklifts are one of the most commonly used types of MHE in warehouses. Regular maintenance is essential to ensure their optimal performance and longevity. Here are some key steps to optimize maintenance for forklifts:

- Perform routine inspections: Implement a regular inspection schedule to identify any potential issues and address them promptly. Inspections should include checking the tires, hydraulic systems, brakes, and other critical components.

- Follow manufacturer’s guidelines: Adhere to the manufacturer’s recommended maintenance schedule, including periodic servicing and replacement of parts. This will help prevent breakdowns and extend the lifespan of the forklift.

- Promote operator training: Properly trained operators can minimize accidents and damage caused by forklift misuse. Conduct regular training sessions to ensure operators are aware of best practices and safety protocols.

By following these maintenance practices, businesses can significantly reduce the risk of forklift downtime and costly repairs. Regular maintenance also contributes to a safer working environment for warehouse personnel.

Optimizing Conveyor Maintenance

Conveyors play a crucial role in warehouse operations by efficiently moving goods from one area to another. To optimize maintenance for conveyors, consider the following strategies:

- Implement a preventive maintenance program: Develop a schedule for routine inspections and maintenance tasks such as lubrication, belt tension adjustment, and motor cleaning. This proactive approach can help identify potential issues before they escalate.

- Train maintenance personnel: Ensure that personnel responsible for conveyor maintenance are well-trained on best practices and safety guidelines. This will enable them to perform maintenance tasks effectively and safely.

- Monitor performance: Make use of sensors and monitoring systems to track the performance and condition of the conveyor system. This data can be used to identify trends, optimize maintenance intervals, and predict possible failures.

- Address issues promptly: When issues are identified, it’s crucial to address them promptly to prevent disruptions in the workflow. Regularly communicating with maintenance personnel and promptly addressing any reported issues will contribute to a smoother operation.

Optimizing conveyor maintenance not only minimizes downtime but also improves overall productivity and efficiency within the warehouse. Taking proactive steps towards maintenance can lead to significant cost savings in the long run.

Maintaining Pallet Jacks for Optimal Performance

Pallet jacks are widely used for short-distance material handling operations in warehouses. To ensure their optimal performance and longevity, the following maintenance practices can be implemented:

- Clean and inspect regularly: Regularly clean pallet jacks to remove dust, dirt, and debris that can impact their performance. Inspect the wheels, forks, and hydraulic systems to identify any signs of wear or damage.

- Lubricate moving parts: Apply appropriate lubrication to the moving parts of the pallet jacks to minimize friction and ensure smooth operation. Follow the manufacturer’s guidelines for the proper lubrication intervals.

- Train operators on proper usage: Educate operators on proper handling techniques and weight limits to prevent overloading and potential damage to the pallet jacks. Regular training sessions can help reinforce these best practices.

Proactive maintenance of pallet jacks not only extends their lifespan but also reduces the risk of operational disruptions and accidents. Implementing a preventive maintenance program ensures that pallet jacks are always in optimal condition for warehouse operations.

In conclusion, optimizing maintenance for different types of Material Handling Equipment is crucial for a well-functioning warehouse. By implementing regular inspections, following manufacturer’s guidelines, promoting operator training, and addressing issues promptly, businesses can ensure the optimal performance, safety, and longevity of MHE. For comprehensive material handling equipment management services, visit HCO Innovations. Their solutions are designed to enhance safety, productivity, efficiency, and cost-effectiveness within warehouse operations.