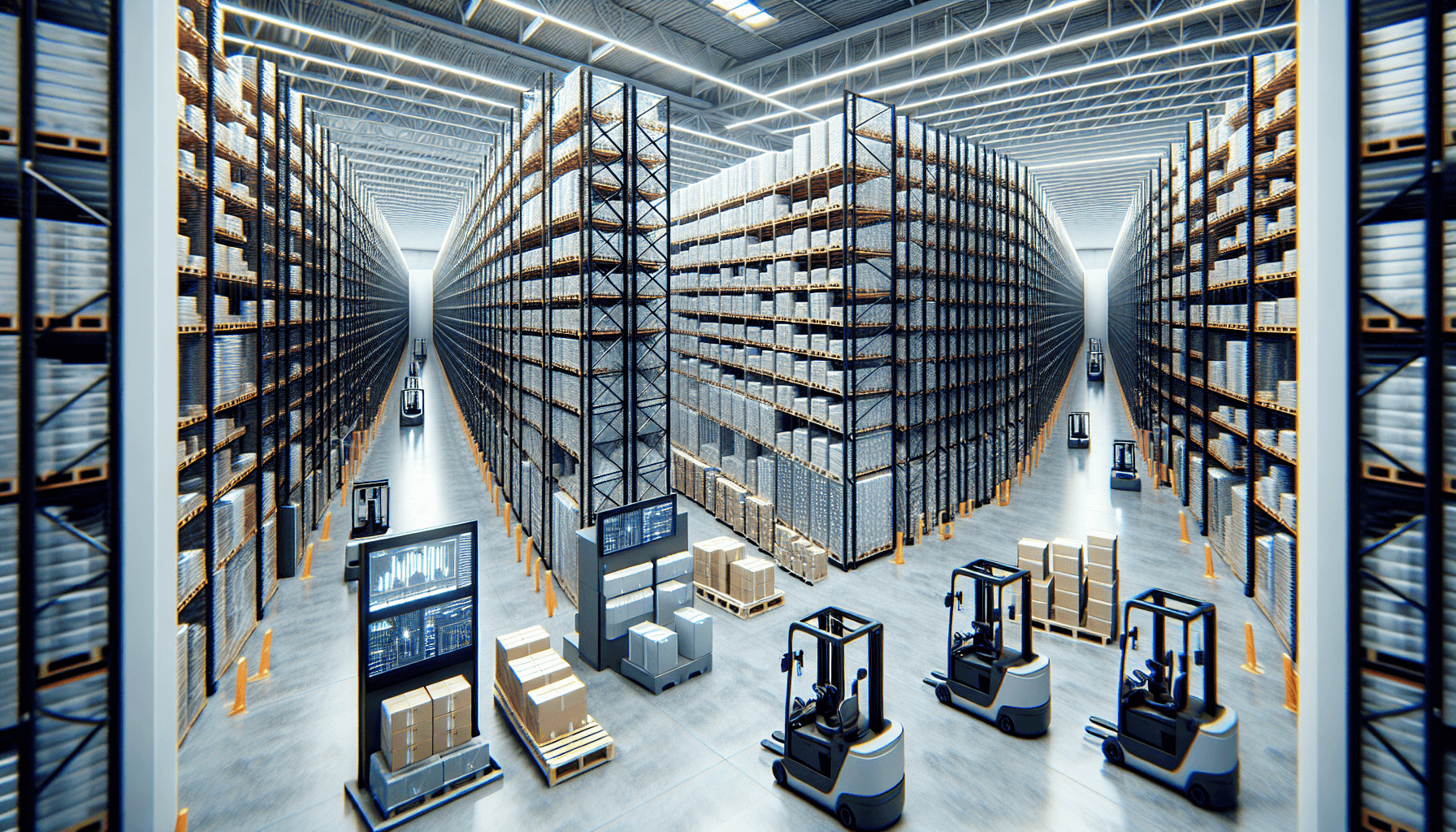

Optimizing material flow is essential for the efficient functioning of high-density warehouses. In these busy and fast-paced environments, it is crucial to streamline the movement of goods to maximize productivity and ensure timely order fulfillment. HCO Innovations, a leading provider of warehouse optimization solutions in Raleigh, NC, specializes in helping businesses enhance material flow within their warehouses. Through a combination of advanced technologies, strategic planning, and operational expertise, HCO Innovations helps businesses achieve seamless material flow and improve overall warehouse performance.

The Importance of Material Flow Optimization

Efficient material flow is vital for several reasons. Let’s explore some of the key benefits of optimizing material flow in high-density warehouses:

- Improved Productivity: By optimizing material flow, businesses can reduce the time spent on tasks such as picking, packing, and shipping. This leads to increased throughput and improved productivity within the warehouse.

- Enhanced Safety: Effective material flow optimization ensures that goods are properly stored and handled, minimizing the risk of accidents and injuries. It includes strategies to prevent congestion, maintain clear aisleways, and utilize proper equipment, contributing to a safer working environment.

- Increased Customer Satisfaction: Smooth material flow enables faster order processing and fulfillment, resulting in improved customer satisfaction. Customers receive their orders promptly, leading to positive feedback, repeat business, and customer loyalty.

- Reduced Costs: Material flow optimization helps businesses minimize handling and storage costs. By eliminating unnecessary movements and utilizing space more efficiently, companies can reduce labor and operational expenses.

- Maximized Space Utilization: High-density warehouses require efficient space utilization to accommodate a large volume of goods. Material flow optimization strategies, such as intelligent racking systems, automated storage, and retrieval systems, and optimized picking paths, help maximize the utilization of available space.

With HCO Innovations, businesses can take advantage of specialized expertise and innovative solutions to optimize material flow in their warehouses. Let’s explore some key strategies that HCO Innovations implements to enhance material flow:

Key Strategies for Optimizing Material Flow

HCO Innovations employs a comprehensive approach to optimize material flow within high-density warehouses. By combining best practices and cutting-edge technologies, they help businesses achieve seamless operations and improved warehouse performance. Some of the key strategies they employ include:

- Warehouse Layout Optimization: HCO Innovations evaluates the existing warehouse layout to identify opportunities for improvement. They consider factors such as product demand, order frequency, and storage requirements to design an efficient layout that minimizes travel time and maximizes material flow.

- Advanced Storage Solutions: HCO Innovations offers advanced storage solutions, such as automated systems, vertical carousels, and dynamic slotting, to optimize storage density and accessibility. These solutions ensure that products are stored in the most appropriate locations, reducing picking time and improving overall efficiency.

- Intelligent Inventory Management: HCO Innovations helps businesses implement intelligent inventory management systems that provide real-time visibility of stock levels. This enables accurate demand forecasting, optimal replenishment, and efficient order fulfillment.

- Optimized Picking Paths: HCO Innovations analyzes the picking paths within the warehouse and identifies the most efficient routes. By minimizing travel distance and optimizing picking sequences, they help businesses streamline the picking process and reduce order processing time.

HCO Innovations also offers material flow evaluation services to assess the current state of warehouse operations and identify areas for improvement. Through data analysis, process mapping, and operational assessments, they provide valuable insights that form the basis for targeted optimization strategies.

Conclusion

Efficient material flow is a crucial aspect of high-density warehouse operations. By optimizing material flow, businesses can achieve improved productivity, enhanced safety, increased customer satisfaction, reduced costs, and maximized space utilization. With HCO Innovations’ warehouse optimization solutions, businesses can leverage advanced technologies and strategic planning to streamline material flow and achieve operational excellence. To get started on transforming your warehouse operations, click here to connect with HCO Innovations.