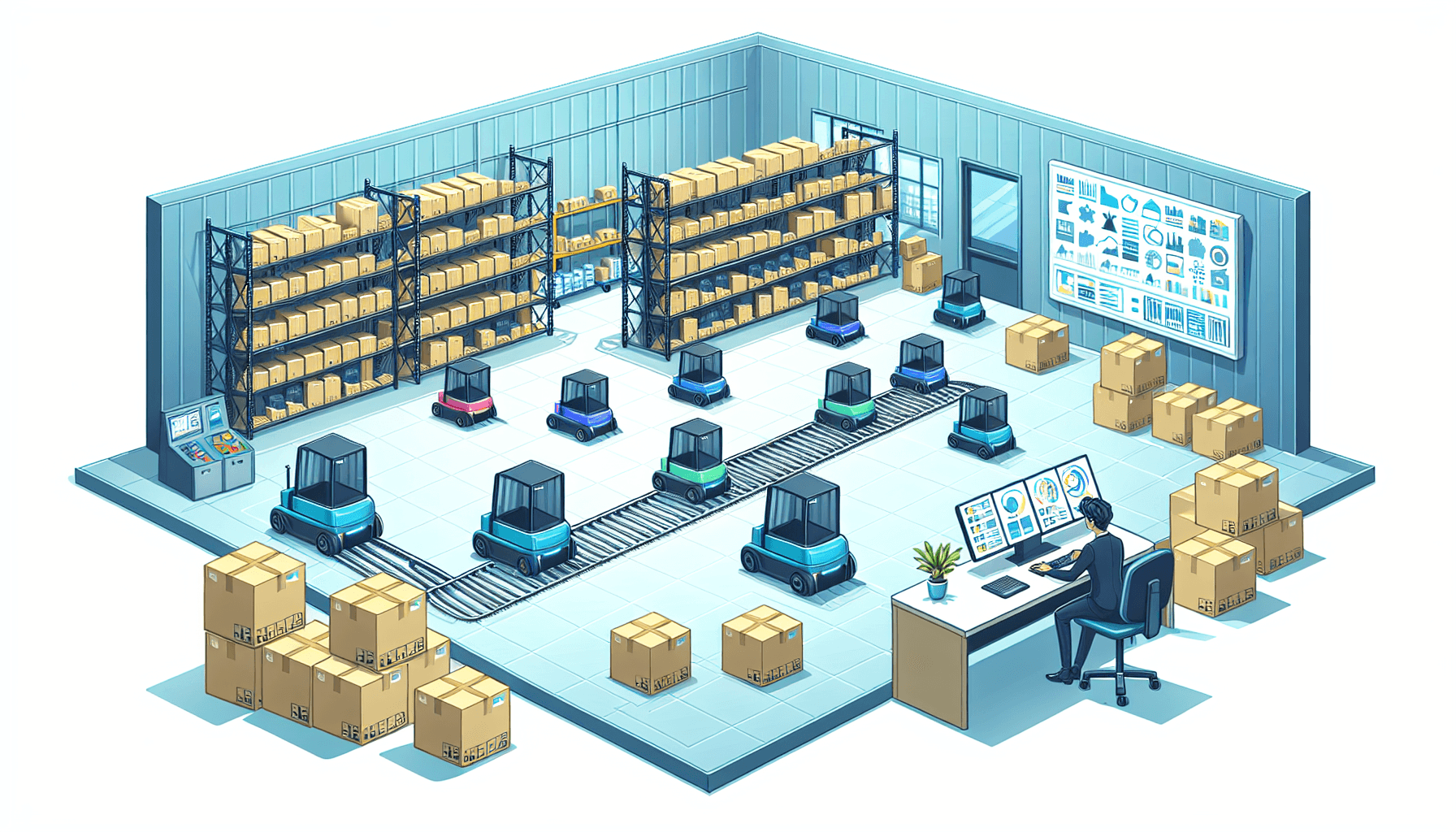

When it comes to optimizing warehouse operations, one technology that has gained significant popularity is Automated Guided Vehicles (AGVs). These intelligent machines have revolutionized the way warehouses operate, improving efficiency, productivity, and safety. If you are considering implementing AGVs in your warehouse, there are several key considerations you should keep in mind.

1. Warehouse Layout and Infrastructure

The first step in choosing the right AGVs for your warehouse is to thoroughly assess your warehouse layout and infrastructure. AGVs operate within predefined routes and require a well-designed layout to navigate efficiently. Consider factors such as aisle width, floor space, and any potential obstacles that AGVs may encounter.

It is also important to evaluate your warehouse infrastructure, including the condition of the floors, the availability of charging stations, and any necessary modifications or upgrades that may be required to accommodate AGVs.

Warehouse optimization solutions offered by HCO Innovations can assist in analyzing your warehouse layout and infrastructure to determine the best AGV deployment strategy.

2. Payload and Weight Capacity

Consider the types of products and materials that will be transported by the AGVs in your warehouse. AGVs come in various sizes and have different weight capacity limits. It is crucial to select AGVs that can handle the payload requirements of your operations. Overloading AGVs can lead to inefficiencies, increased maintenance costs, and potential safety hazards.

Work closely with a reputable AGV provider like HCO Innovations to accurately assess your payload requirements. They will help you choose AGVs that can handle the weight of your products while maximizing efficiency.

3. Navigation and Safety Features

The navigation and safety features of AGVs are critical factors to consider when selecting the right AGVs for your warehouse. AGVs use various technologies for navigation, such as lasers, cameras, or magnetic strips. Each technology has its advantages and limitations.

Consider the complexity of your warehouse environment and the level of precision required for AGV navigation. For example, if you have narrow aisles or require AGVs to work in close proximity to humans, you will need AGVs with advanced collision avoidance systems and reliable safety features.

HCO Innovations specializes in providing AGVs with advanced navigation and safety features to ensure smooth and safe operations within your warehouse.

4. Integration with Warehouse Management System

AGVs are most effective when seamlessly integrated with your Warehouse Management System (WMS). When choosing AGVs, consider their compatibility with your existing WMS or the potential to integrate them with a new WMS.

An integrated system allows for real-time communication between the AGVs and the WMS, enabling efficient coordination, tracking, and optimization of warehouse tasks. This integration improves overall productivity and enables better decision-making based on accurate data.

The experts at HCO Innovations can assist you in selecting AGVs that are compatible with your WMS and provide seamless integration.

5. Scalability and Future Growth

When choosing AGVs, it is crucial to consider the scalability of your operations and any potential future growth. AGVs are a long-term investment, and it is essential to select AGVs that can adapt to your evolving business needs.

Consider the flexibility of the AGVs in terms of route changes or payload adjustments. Additionally, ensure that the AGVs can easily accommodate any expansion plans or changes in warehouse layout.

HCO Innovations can help you select AGVs that are scalable and can grow alongside your business, providing you with long-term value.

In conclusion, choosing the right AGVs for your warehouse requires careful consideration of factors such as warehouse layout, payload and weight capacity, navigation and safety features, integration with your WMS, and scalability for future growth. By partnering with a knowledgeable and experienced AGV provider like HCO Innovations, you can ensure a successful AGV deployment that enhances safety, productivity, efficiency, and cost-effectiveness within your warehouse operations.

What are AGVs and how do they work?

AGVs, or Automated Guided Vehicles, are robotic vehicles designed to perform tasks in a warehouse or industrial environment without direct human intervention. They typically use sensors, cameras, or laser guidance systems to navigate and make decisions, allowing them to move materials or products from one location to another efficiently.

What are the benefits of using AGVs in a warehouse?

There are several benefits to using AGVs in a warehouse. They can increase productivity by automating material handling tasks, reduce labor costs by eliminating the need for manual labor, improve safety by minimizing accidents and injuries, optimize space utilization by efficiently utilizing storage areas, and enhance accuracy by reducing human errors in product movement.

How do I determine the right type of AGV for my warehouse?

Choosing the right type of AGV for your warehouse requires careful consideration of several factors. You need to assess your warehouse layout, including the size, shape, and accessibility of the aisles and storage areas. Additionally, you should evaluate the types of materials or products that need to be transported, the weight and dimensions of the loads, and the required speed and throughput. It is also essential to consider your budget, infrastructure requirements (such as charging stations or wireless communication), and future scalability needs.

What safety features should I look for in AGVs?

When selecting AGVs for your warehouse, it is crucial to prioritize safety features. Look for AGVs equipped with collision avoidance systems, such as sensors or cameras, to detect obstacles and avoid collisions. Emergency stop buttons, sound alarms, or flashing lights should also be present to ensure immediate action can be taken if necessary. Additionally, AGVs with clear visual indications, like warning signs or lights, can help alert nearby employees to their presence.

What maintenance is required for AGVs?

AGVs require regular maintenance to ensure optimal performance and durability. This can include routine cleaning of the vehicle and sensors, inspecting and replacing worn parts as necessary, calibrating sensors and navigation systems, and monitoring battery health. It is essential to follow the manufacturer's recommended maintenance schedule and procedures for each specific AGV model to maximize their lifespan and functionality.

How can AGVs integrate with existing warehouse management systems?

AGVs can seamlessly integrate with existing warehouse management systems (WMS) through various methods. This integration enables real-time communication between the AGVs and the WMS, allowing for efficient task assignment, tracking, and inventory management. AGVs can use technologies such as wireless communication protocols or APIs to exchange data with the WMS, ensuring accurate and synchronized information flow between the AGVs and other warehouse operations.

What are the key cost factors to consider when investing in AGVs?

When investing in AGVs, several cost factors need to be considered. These include the initial purchase or lease cost of the AGVs themselves, any required infrastructure modifications or additions (such as charging stations or navigation markers), ongoing maintenance and repair expenses, training costs for employees, and potential productivity gains and labor cost reductions over time. It is crucial to conduct a thorough cost-benefit analysis to determine the long-term financial impact of adopting AGVs in your warehouse.

Warehouse AGV Implementation Success Stories

Warehouse AGV Implementation Success Stories

Introduction

In today's fast-paced and highly competitive business environment, warehouse operations play a crucial role in ensuring smooth and efficient supply chain management. With the increasing volume of materials to be handled and the need for improved productivity, many companies are turning to innovative solutions to optimize their warehouse operations. One of the most significant advancements in warehouse automation is the implementation of Automated Guided Vehicles (AGVs).

What are AGVs?

AGVs are autonomous vehicles that are designed to move and transport materials within a warehouse or distribution center, without the need for human intervention. They are equipped with advanced sensors and control systems that allow them to navigate through the warehouse, avoiding obstacles and following pre-defined paths. AGVs can be used to perform a wide range of tasks, including picking and placing products, transporting pallets, and even sorting and loading items onto trucks.

AGVs offer several advantages over traditional manual material handling methods. They are highly efficient, capable of working 24/7 without breaks, reducing the time needed for material transportation. AGVs also improve safety by minimizing the risk of accidents caused by human error. Additionally, AGVs can be easily integrated with other warehouse automation technologies, such as conveyor systems and robotic arms, further enhancing operational efficiency.

Real-Life Success Stories

Let's explore some real-life examples of companies that have successfully implemented AGVs in their warehouse operations:

1. XYZ Manufacturing

XYZ Manufacturing, a leading player in the automotive industry, faced several challenges in their warehouse operations, primarily related to material handling inefficiencies and workforce allocation. They implemented AGVs to automate their material transportation tasks, such as moving heavy components from the storage area to the production line. The AGVs significantly improved efficiency by reducing the time required for material movement and eliminating the need for manual labor for such repetitive tasks. This allowed the workers to focus on more value-added activities and increased productivity. The successful implementation of AGVs resulted in a significant reduction in material handling costs and improved overall warehouse operations.

2. ABC Distribution

ABC Distribution, a large e-commerce player, was struggling with a high volume of orders and an increasing number of returns. They implemented AGVs to optimize their order fulfillment process. The AGVs were used to pick and transport products from the storage area to the packing stations. With the help of advanced software integration, the AGVs were able to prioritize and optimize the picking routes, resulting in faster and more accurate order fulfillment. This not only reduced the order processing time but also improved customer satisfaction by ensuring timely deliveries. The implementation of AGVs helped ABC Distribution cope with their growing business demands and achieve significant cost savings.

3. DEF Logistics

DEF Logistics, a third-party logistics provider, faced challenges in managing their warehouse operations efficiently, primarily due to the complexity of handling a wide range of products for different clients. They implemented AGVs to streamline their inventory management and sorting processes. The AGVs were used to transport items from receiving docks to the designated storage locations, ensuring accurate inventory tracking and reducing the risk of misplaced or damaged goods. Additionally, the AGVs were utilized to sort and consolidate orders for outbound shipments, reducing order processing time and improving overall operational efficiency. The implementation of AGVs helped DEF Logistics provide faster and more reliable services to their clients, enhancing customer satisfaction and gaining a competitive edge in the market.

Conclusion

Warehouse AGV implementation has proven to be a game-changer for companies across industries. By leveraging the power of automation, companies can transform their warehouse operations, achieving significant cost savings, improving productivity, and enhancing customer satisfaction. As the technology continues to advance, we can expect even more innovative applications of AGVs in the future. If you are interested in optimizing your warehouse operations and reducing material handling costs, consider partnering with a trusted management consulting firm like HCO Innovations. They specialize in warehouse optimization and forklift fleet management, providing comprehensive services tailored to your specific needs. Visit their website here to learn more about how they can help you achieve operational excellence.