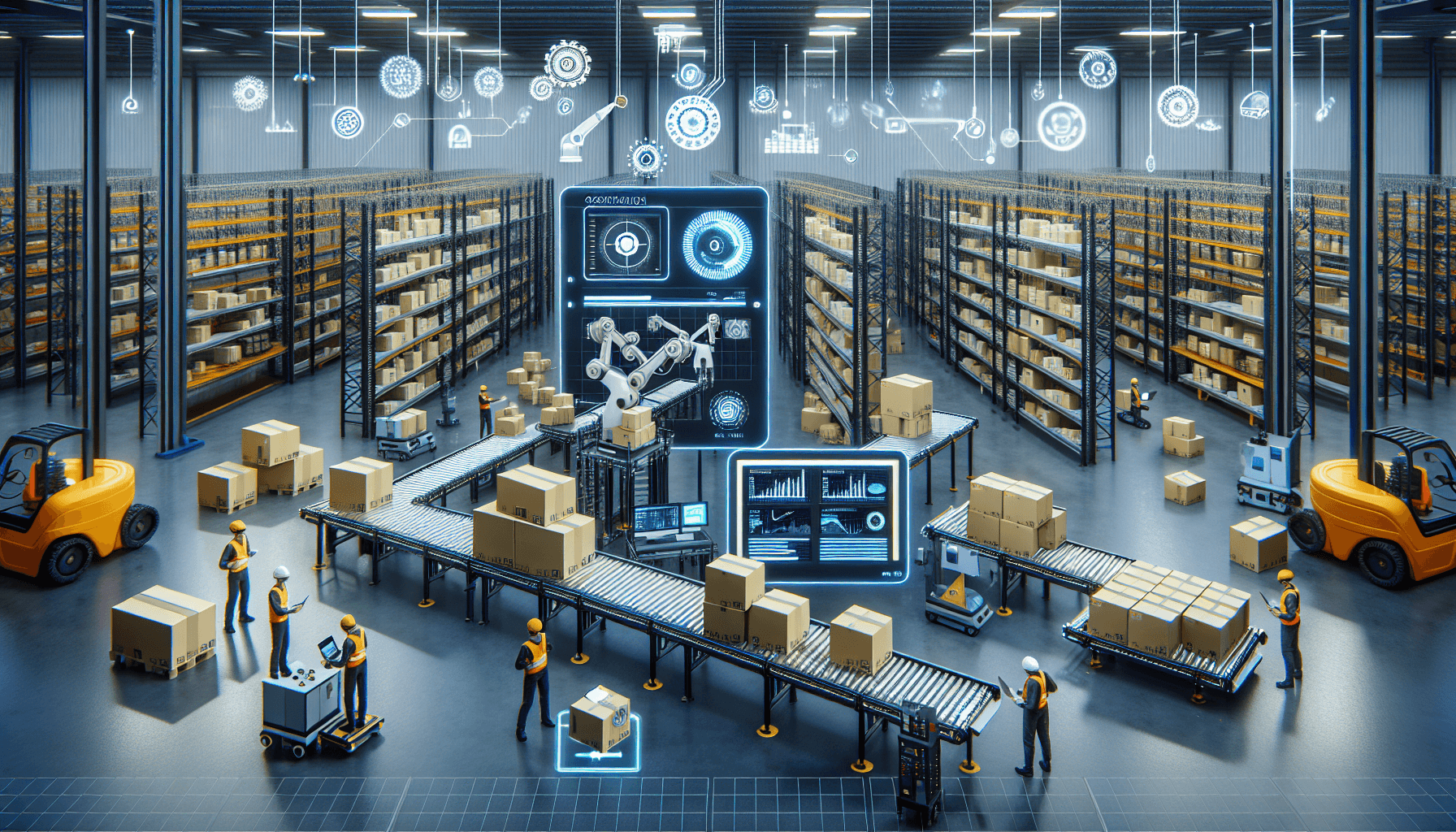

Warehouse operations are a critical component of supply chain management. Efficient and effective warehouse operations can have a significant impact on a company’s overall productivity and profitability. One of the key aspects of optimizing warehouse operations is the implementation of integrated material handling systems. In this article, we will explore the benefits of integrating material handling systems within warehouses and how it can enhance safety, productivity, efficiency, and cost-effectiveness.

Improved Safety

When it comes to warehouse operations, safety should always be a top priority. Integrated material handling systems can greatly contribute to improving safety within the warehouse environment. These systems are designed to streamline and automate various material handling tasks, reducing the need for manual interventions. By minimizing manual handling of heavy and bulky items, the risk of accidents and injuries can be significantly reduced.

Additionally, integrated material handling systems often incorporate safety features such as sensors, alarms, and emergency stop buttons. These features help prevent collisions, identify potential hazards, and provide immediate alerts to operators. Furthermore, by utilizing automation technologies like robotics and conveyor systems, workers can be relieved from physically demanding tasks, reducing the risk of strains and musculoskeletal injuries.

The implementation of integrated material handling systems enables warehouse operators to create a safer working environment for their employees, reducing the occurrence of accidents and enhancing overall warehouse safety.

Enhanced Productivity

Another significant benefit of integrated material handling systems is the improvement in productivity levels within the warehouse. These systems automate various material handling tasks, eliminating or minimizing time-consuming and repetitive manual processes. Instead of relying solely on manual labor, workers can focus on more value-added activities such as inventory management, picking, and packing.

Integration of material handling systems with warehouse management software allows for seamless communication and optimized coordination between different processes. This means that inventory levels, order fulfillment, and picking processes can be continuously updated and monitored in real-time, enhancing overall productivity. With the help of barcode scanning, RFID technology, and automated sorting systems, material handling systems can significantly reduce order processing times and increase order accuracy.

Furthermore, the implementation of automated guided vehicles (AGVs) or robotic systems for material movement enables warehouses to operate 24/7 without interruptions. These systems can efficiently carry out material handling tasks, reduce idle time, and eliminate human errors, contributing to increased productivity levels.

Improved Efficiency

Integrated material handling systems also offer improved efficiency within warehouse operations. By automating various processes, these systems eliminate bottlenecks and streamline workflows. For example, automated conveyor systems can facilitate the smooth flow of goods, minimizing delays and congestion.

Additionally, material handling systems can optimize space utilization within the warehouse. Utilizing technologies such as automated storage and retrieval systems (AS/RS) allows for efficient vertical storage and retrieval of items, maximizing the use of available space. This not only increases storage capacity but also reduces the time spent on searching for items, improving efficiency and order fulfillment.

Moreover, integrated material handling systems often come with advanced analytics capabilities, providing valuable insights into warehouse operations. By analyzing data on inventory levels, order patterns, and operational performance, warehouses can identify areas for improvement and make data-driven decisions to enhance overall efficiency.

Cost-Effectiveness

Implementing integrated material handling systems can lead to significant cost savings for warehouses. By improving safety and reducing the risk of accidents and injuries, businesses can minimize costly workers’ compensation claims and potential legal liabilities. Additionally, with automated processes and efficient workflows, labor costs can be optimized as workers can focus on higher-value tasks, rather than spending time on manual material handling activities.

Furthermore, integrated material handling systems contribute to reducing operational costs associated with errors and inefficiencies. By automating picking, packing, and sorting processes, accuracy levels can be significantly improved, reducing the likelihood of incorrect shipments or missed orders. This minimizes costs associated with returns, re-shipping, and customer dissatisfaction.

Additionally, optimized space utilization and improved inventory management made possible by material handling systems can help reduce costs associated with excess inventory, storage rental, and wastage. With real-time visibility into inventory levels, businesses can manage inventory more efficiently, avoiding overstocking or stockouts.

In conclusion, the integration of material handling systems offers a wide range of benefits for warehouses. From improved safety and enhanced productivity to increased efficiency and cost-effectiveness, these systems play a crucial role in optimizing warehouse operations. To explore HCO Innovations’ material handling equipment management solutions, visit our website.