When it comes to warehouse operations, one of the key factors that directly impacts delivery times is the efficiency of material flow. A well-optimized material flow system can significantly reduce delays, improve productivity, and ultimately enhance customer satisfaction. In this article, we will explore the importance of material flow and how it can have a positive impact on delivery times.

The Flow of Materials

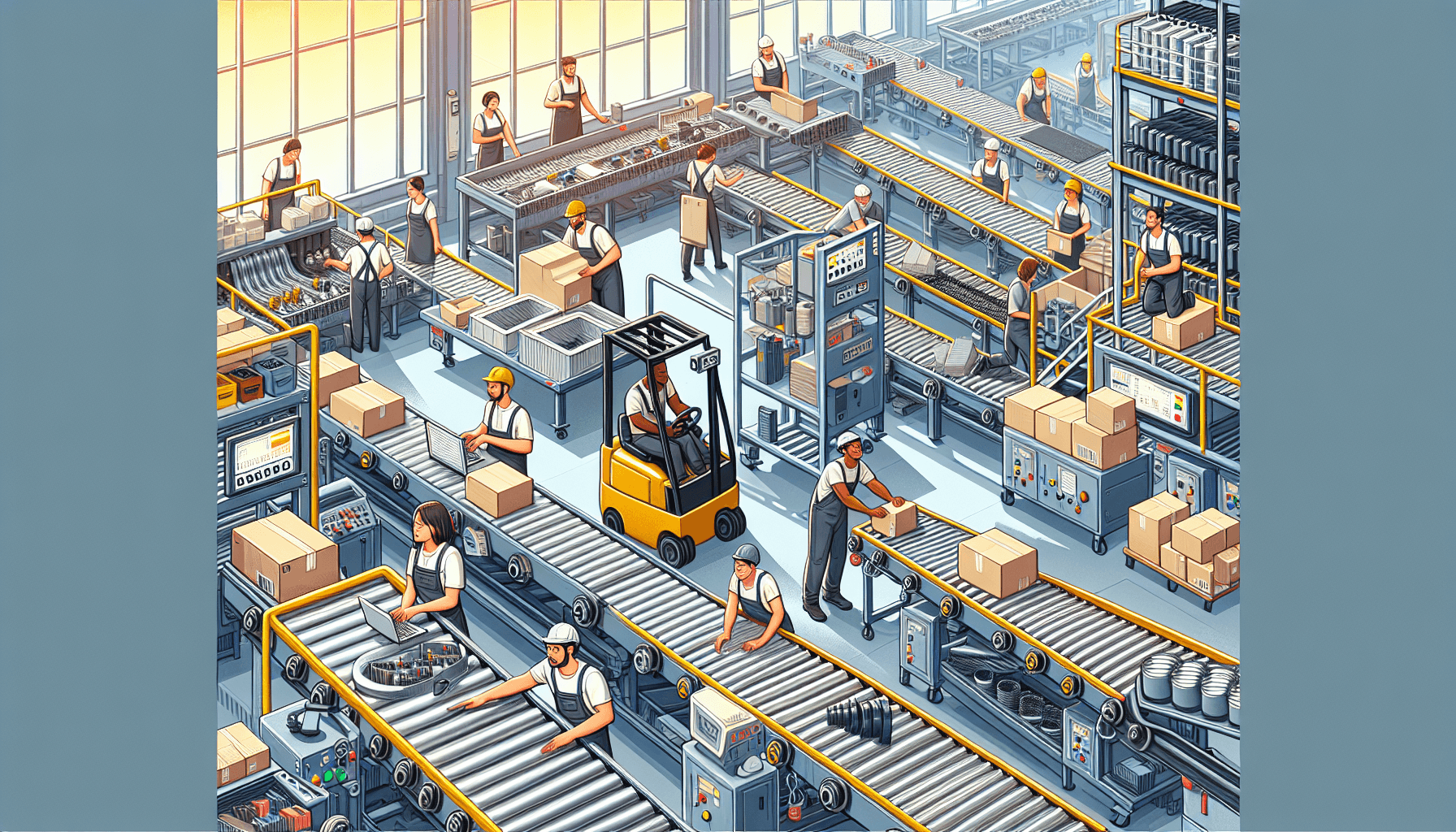

In a warehouse environment, the flow of materials refers to the movement of goods and inventory from the receiving area to the storage areas, order picking, packing, and finally to the shipping area. It involves various processes such as unloading, put-away, retrieval, and loading. A streamlined material flow ensures that products move seamlessly through these processes, minimizing bottlenecks and reducing the time taken to fulfill orders.

Efficient material flow is crucial for meeting customer demands within the specified timeframes. When materials are flowing smoothly, it allows for faster order processing, reducing lead times and ensuring timely deliveries. On the other hand, inefficient material flow can result in delays, errors, and increased costs.

The Impact on Delivery Times

Optimizing material flow has a direct impact on delivery times. Here are some ways that an efficient material flow system can help expedite deliveries:

Reduced Processing Time

A well-designed material flow system eliminates unnecessary steps and reduces the time it takes to process orders. By minimizing travel distances, eliminating double handling, and organizing inventory for easy access, warehouse operators can significantly shorten the time required to pick and pack orders. This leads to faster order fulfillment and shorter delivery times.

Improved Order Accuracy

An optimized material flow system reduces the chances of errors during order picking and packing. By implementing efficient processes such as batch picking and using technology like barcode scanners and automated systems, warehouse operators can improve order accuracy. This helps avoid the time-consuming task of correcting errors and re-shipping incorrect orders, ultimately resulting in improved delivery times.

Enhanced Visibility and Tracking

Implementing a robust material flow system can provide real-time visibility and tracking of inventory throughout the warehouse. This enables warehouse managers to monitor the status and location of items at any given time. Improved visibility allows for better planning, coordination, and proactive management of potential delays. It also enables better communication with customers regarding the status of their orders, leading to increased customer satisfaction.

Better Utilization of Resources

Efficient material flow allows for better utilization of resources within the warehouse. This includes optimizing space, labor, and equipment. By arranging product placement strategically and minimizing unnecessary movements, warehouse operators can maximize the use of available space and reduce congestion. This, in turn, improves the efficiency of operations, reduces costs, and enables faster movement of goods, ultimately contributing to shorter delivery times.

Continuous Improvement

An effective material flow system is not a one-time implementation, but a continuous improvement process. Warehouse operators should regularly evaluate and analyze their material flow processes to identify areas for optimization. By conducting periodic material flow evaluations (learn more here), warehouse operators can uncover bottlenecks, inefficiencies, or areas that could benefit from automation or improved workflows. Making necessary adjustments based on these evaluations helps to streamline operations further and reduce delivery times.

Conclusion

In summary, material flow plays a vital role in warehouse operations and has a direct impact on delivery times. By streamlining processes, improving order accuracy, enhancing visibility, optimizing resource utilization, and continually striving for improvement, warehouse operators can significantly reduce lead times and provide faster and more reliable deliveries. Investing in warehouse optimization solutions, like those offered by HCO Innovations, can help businesses achieve a well-designed and efficient material flow system, positively impacting their delivery times and overall operational success.