In today’s fast-paced supply chain industry, efficiency and optimization are crucial factors for success. Warehouse operations play a vital role in ensuring smooth and streamlined supply chain processes. However, warehouses often face challenges such as bottlenecks that can hinder productivity and result in delays and increased costs.

The Impact of Bottlenecks in Warehouse Operations

A bottleneck can be defined as a point in the warehouse operations where the flow of materials or information is constrained, causing a slowdown in overall efficiency. These bottlenecks can occur at different stages of the supply chain, including receiving, picking, packing, and shipping.

When bottlenecks occur, several negative consequences can arise. Firstly, it can lead to delays in order processing and fulfillment, resulting in dissatisfied customers. Secondly, bottlenecks can create inefficiencies in labor utilization, as workers may be idle or unable to perform their tasks effectively. Moreover, bottlenecks can also impact the accuracy of inventory management and increase the risk of inventory shortages or overstocks.

To address these challenges, warehouse operators need to implement solutions that can optimize their operations and reduce the occurrence of bottlenecks. One such solution is the effective management of material handling equipment (MHE).

The Role of Material Handling Equipment (MHE) in Reducing Bottlenecks

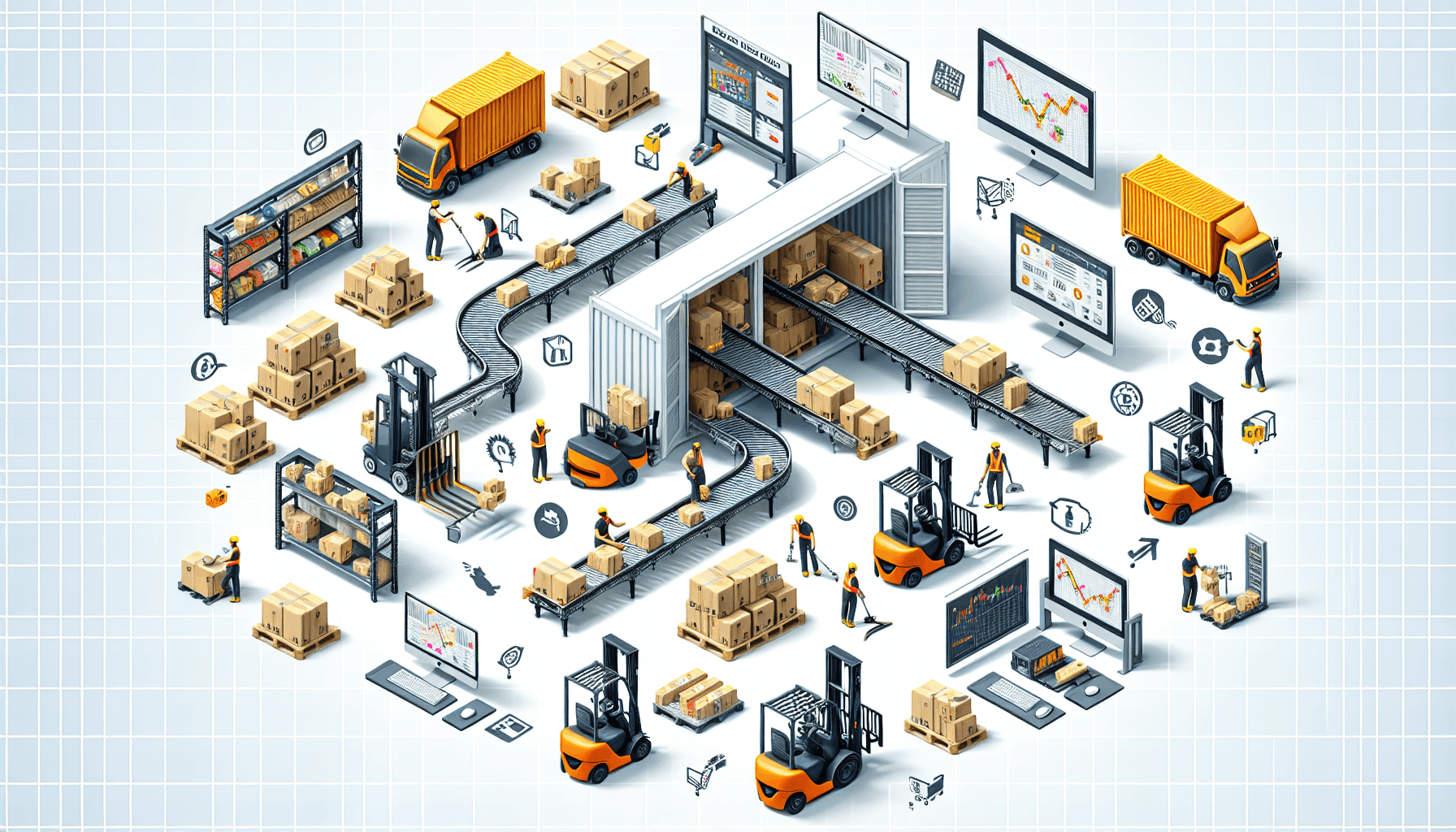

Material handling equipment encompasses a variety of tools and machinery used to move, store, and transport goods within a warehouse. Efficient management of MHE can significantly contribute to reducing bottlenecks and improving overall warehouse performance. Here’s how:

1. Streamlined Inventory Flow

By utilizing the right MHE, warehouse operators can ensure the smooth flow of inventory from one location to another. This includes equipment such as forklifts, pallet jacks, conveyors, and automated guided vehicles (AGVs). These tools enable faster and more efficient movement of goods, reducing the time spent on manual handling and minimizing the risk of errors or damage during transportation.

MHE can also enable optimal space utilization by facilitating efficient stacking and storage of inventory. By utilizing vertical space effectively and implementing well-organized racking systems, warehouses can maximize their storage capacity and minimize congestion, leading to streamlined inventory flow.

2. Improved Warehouse Layout and Design

Efficient utilization of MHE requires careful planning of warehouse layout and design. By analyzing the flow of goods, warehouse operators can strategically position MHE and storage systems to minimize travel distances and eliminate or reduce bottlenecks. This includes identifying optimal locations for receiving, picking, packing, and shipping areas, as well as implementing efficient pathways to ensure smooth movement of goods.

A well-designed warehouse layout combined with the effective placement of MHE can significantly enhance productivity and reduce the time required for material handling operations.

3. Automation and Robotics

Automation and robotics have revolutionized warehouse operations by introducing advanced technologies that can further eliminate bottlenecks. Automated systems, such as conveyor systems and robotic picking systems, can handle repetitive tasks efficiently and accurately, reducing the reliance on manual labor and minimizing the risk of errors and delays.

By implementing automation and robotics, warehouse operators can increase throughput, improve order accuracy, and enhance overall operational efficiency. These technologies can handle large volumes of orders and perform tasks round the clock, ensuring faster turnaround times and reducing the chances of bottlenecks occurring.

4. Real-time Data and Analytics

Another way MHE helps in reducing bottlenecks is by providing real-time data and analytics. Modern equipment is equipped with sensors and tracking systems that capture valuable data about operations, such as equipment utilization rates, inventory levels, and order fulfillment metrics.

By leveraging this data, warehouse operators can gain insights into their operations, identify potential bottlenecks, and make informed decisions to optimize processes. Intelligent MHE management systems coupled with data analytics can facilitate predictive maintenance, demand forecasting, and inventory optimization, further reducing the chances of bottlenecks occurring.

Implementing comprehensive MHE management solutions can streamline warehouse operations, reduce bottlenecks, and ultimately lead to improved safety, productivity, efficiency, and cost-effectiveness.

If you’re looking for professional guidance and solutions for effective MHE management, HCO Innovations can help. With their expertise in warehouse optimization solutions, they offer innovative technologies and strategies to enhance safety, productivity, and efficiency within warehouse operations. Check out their MHE management solutions to discover how they can assist your organization in reducing supply chain bottlenecks and optimizing your warehouse operations.