Forklifts don’t lie, but they don’t talk either. If they’re sitting too long, running too hot, breaking down too often—you won’t know unless you’re looking. And that’s the whole deal with utilization metrics. They’re not for show. They’re for control. If you don’t know what your fleet is doing, you’re not managing it. You’re just watching it happen.

Some warehouses run too many lifts. Others not enough. Most aren’t sure. One operator burns through propane in a day, the next barely scratches the tank. Why? Could be routes. Could be habits. Could be downtime nobody’s tracking. You won’t catch any of that without the numbers. And I mean the real numbers—not guesses, not clipboards, not “Jim said it was fine.”

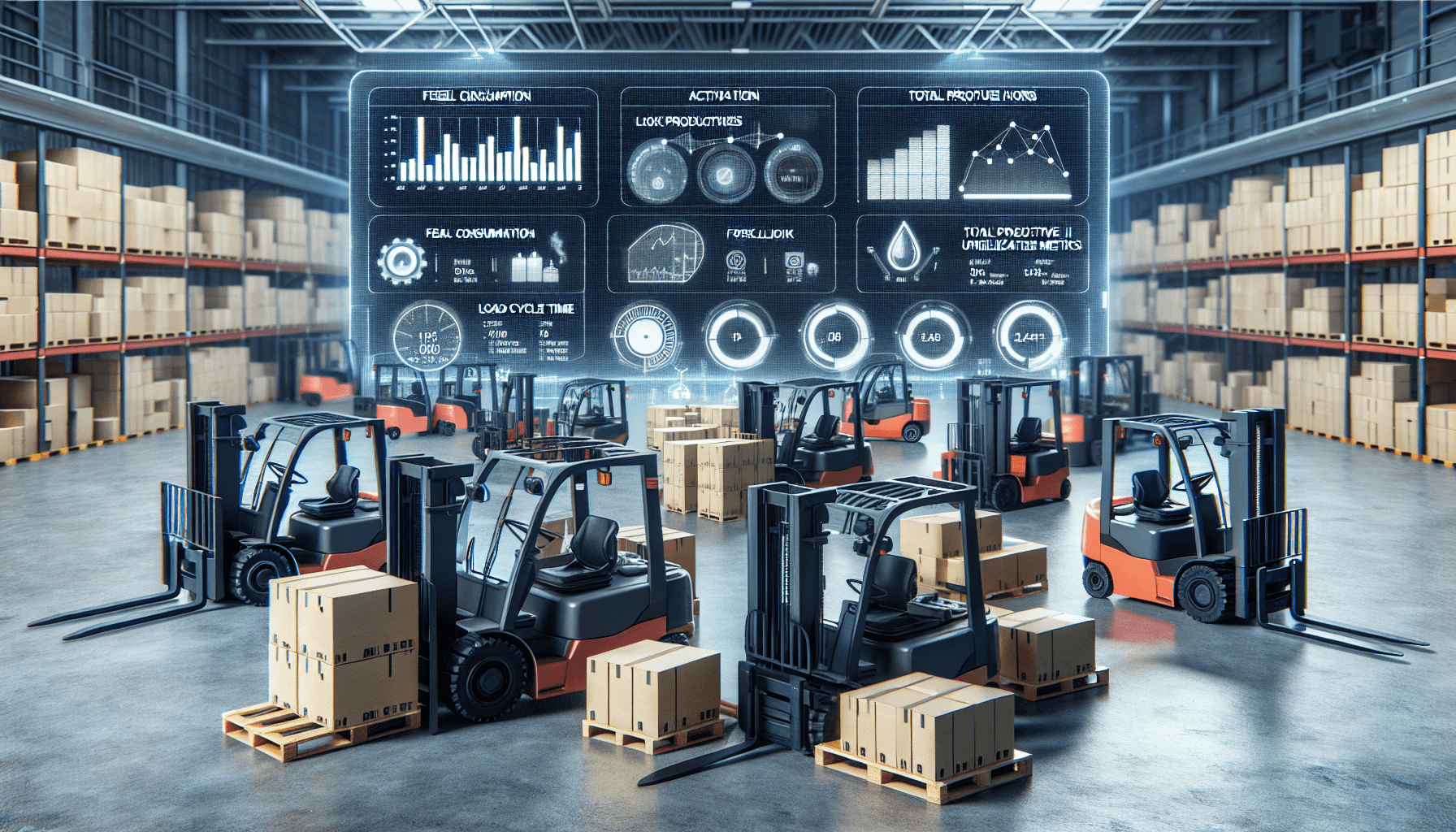

What to Track—And Why It Matters

These metrics aren’t fancy. They’re basic. But basic works:

- Utilization Rate – How much time is the forklift actually in use? Not parked, not idling. Working. Low numbers here? You’ve got excess iron sitting around draining insurance.

- Idle Time – Nobody likes to admit it, but half the fleet might be napping half the day. Track it. Trim the fat.

- Fuel Usage – Spikes mean something’s wrong. Could be overuse. Could be an engine working harder than it should. Could be someone revving through the aisles like it’s a drag race. You won’t know unless you see the trend.

- Maintenance Logs – Every breakdown leaves a trail. The patterns are there—if you’re willing to dig.

And don’t forget labor. Machines are part of it, but so are the people running them. Are they sitting around waiting on equipment? Or are the lifts waiting on them? Either way, you’re bleeding time.

How to Actually Use the Data

Getting metrics is easy. Every software vendor will promise you charts and dashboards. The hard part? Using them. Here’s what that looks like in the real world:

Step one: Decide what problem you’re solving. Too many forklifts? Too much fuel spend? Missed ship times? Pick one. Start there.

Step two: Choose a few key metrics. Not everything. Just the ones tied to that one problem. Keep it tight, or the data becomes noise.

Step three: Get the right tools. You don’t need some monster platform if all you want is runtime and idle time. But you do need something that captures it without operator input. Trust me—manual logs die in three weeks.

Step four: Train your people. If they don’t get it, they won’t care. If they don’t care, they’ll ignore the tools. Then you’re back to step zero.

Step five: Review regularly. I mean actually sit down and look. Every two weeks. Monthly at worst. Find the weird stuff. Question it. Fix it. Repeat.

Is it perfect? No. It never is. You’ll miss things. You’ll chase the wrong problem now and then. That’s okay. What matters is movement. Improvement. Looking at numbers, making a call, trying something different. Again and again and again.

Utilization metrics aren’t about being high-tech. They’re about being dialed in. You want fewer surprises. Fewer “what happened?” moments. You want to look at a number and say, “Yeah, that tracks.” When the data lines up with what you see on the floor, you’re doing it right.

And if the numbers surprise you? Even better. That means you’re learning something. That means it’s working.