Managing a forklift fleet can quickly become a drain on time, resources, and capital. Maintenance headaches, compliance demands, and unpredictable downtime—if you’re managing all of it in-house, you already know how complex it can get. That’s why many companies are turning to outsourced forklift fleet management. And the results? Leaner operations, lower costs, and more room to focus on what matters most: growing the business.

Why Outsourcing Makes Sense

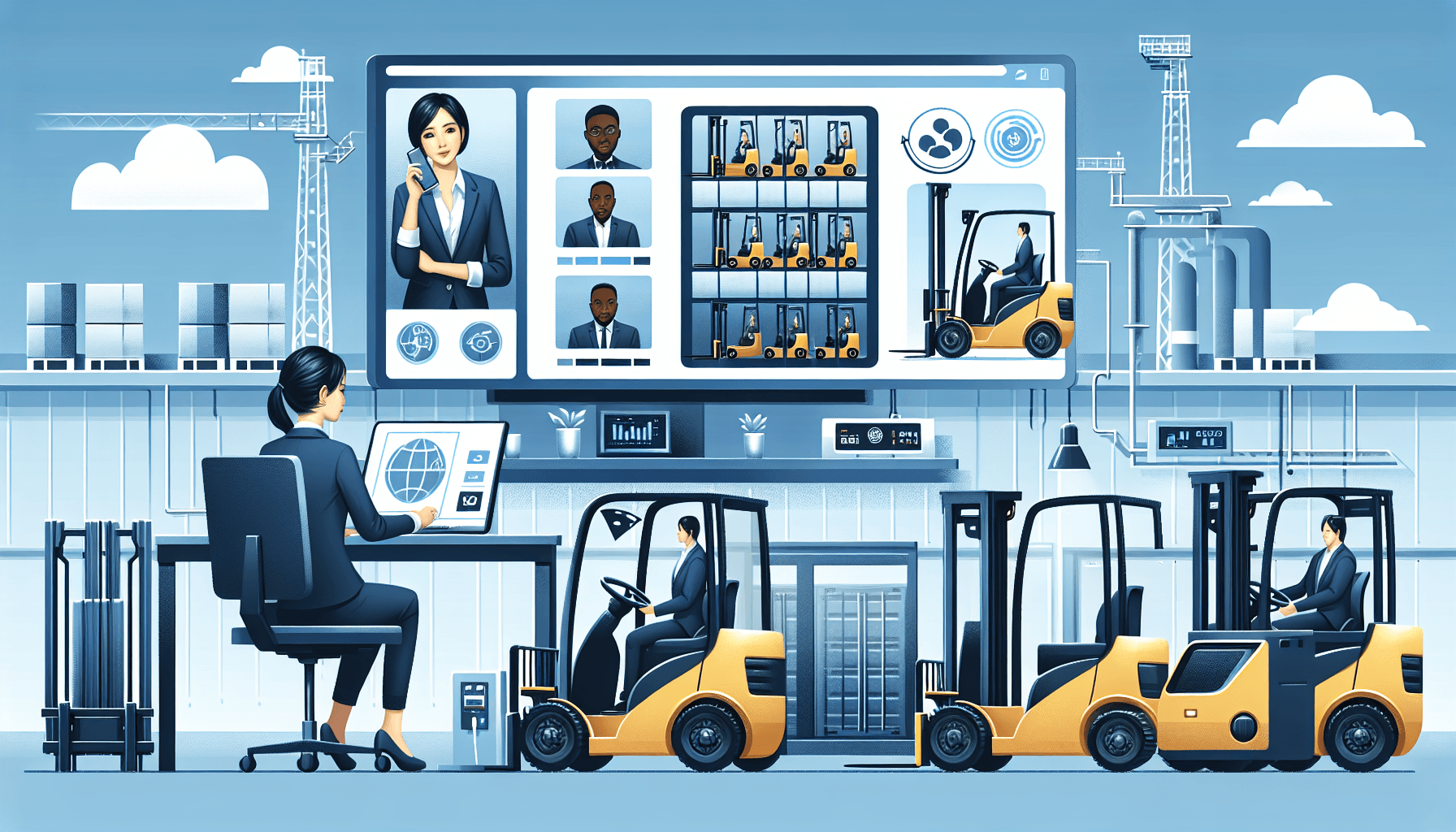

Forklift fleet management isn’t just about scheduling repairs—it’s a continuous balancing act of uptime, safety, compliance, and cost control. By partnering with a professional fleet management provider, you’re not handing off responsibility—you’re gaining a team of specialists equipped with the tools, data, and experience to manage your fleet better than ever.

Boost Efficiency. Cut Downtime.

Outsourced providers don’t guess. They use fleet analytics, real-time monitoring, and predictive maintenance systems to ensure your forklifts stay on the floor, not in the shop. Every hour of uptime matters, and with optimized scheduling and proactive service, downtime is minimized. Your team stays productive, your operations stay lean.

Reduce Operating Costs

Running an internal fleet management program can eat up your budget fast—dedicated staff, diagnostic tools, maintenance software, and unexpected repair bills all add up. When you outsource, these costs are bundled into a predictable service fee. No surprises, no scramble. Just reliable service and measurable savings.

Outsourcing also gives you access to negotiated rates on parts, equipment, and services—deals that only seasoned providers with purchasing power can secure. It’s a smarter spend, and it keeps your overhead in check.

Stay Compliant, Stay Safe

Regulations change. Safety standards evolve. Outsourced partners stay ahead of those shifts so you don’t have to. They manage training, safety inspections, and regulatory compliance, reducing risk and liability. Forklifts stay safe. Operators stay trained. You stay protected.

Keep Your Team Focused

Every minute your managers spend chasing down fleet issues is time taken away from strategic work. Outsourcing lets your team get back to doing what they do best—building your business. Let the fleet experts handle the diagnostics, maintenance, and compliance tracking, while your in-house team focuses on growth, not grease.

Conclusion

Outsourcing forklift fleet management isn’t a cost—it’s an investment in operational clarity and performance. From improved uptime and lower costs to better safety and sharper focus, the benefits ripple throughout the organization. Whether your fleet is a handful of lifts or a multi-site operation, outsourcing could be the strategic shift that takes your warehouse to the next level.

HCO Innovations specializes in full-service forklift fleet management. Their turnkey programs are designed to reduce material handling costs, increase visibility, and give you full confidence in your operations. If you’re ready to take the next step, reach out to HCO Innovations at 1-888-755-9566 or info@hcoinnovations.com.